Microfluidics enables precise manipulation of fluids at the microscale, facilitating complex biological analyses with minimal reagent consumption. Lab-on-a-chip integrates microfluidic components into a single device, allowing streamlined workflows for diagnostics, cell culture, and biochemical assays. The synergy between microfluidics and lab-on-a-chip technology revolutionizes biological engineering by enhancing automation, portability, and sensitivity in experimental procedures.

Table of Comparison

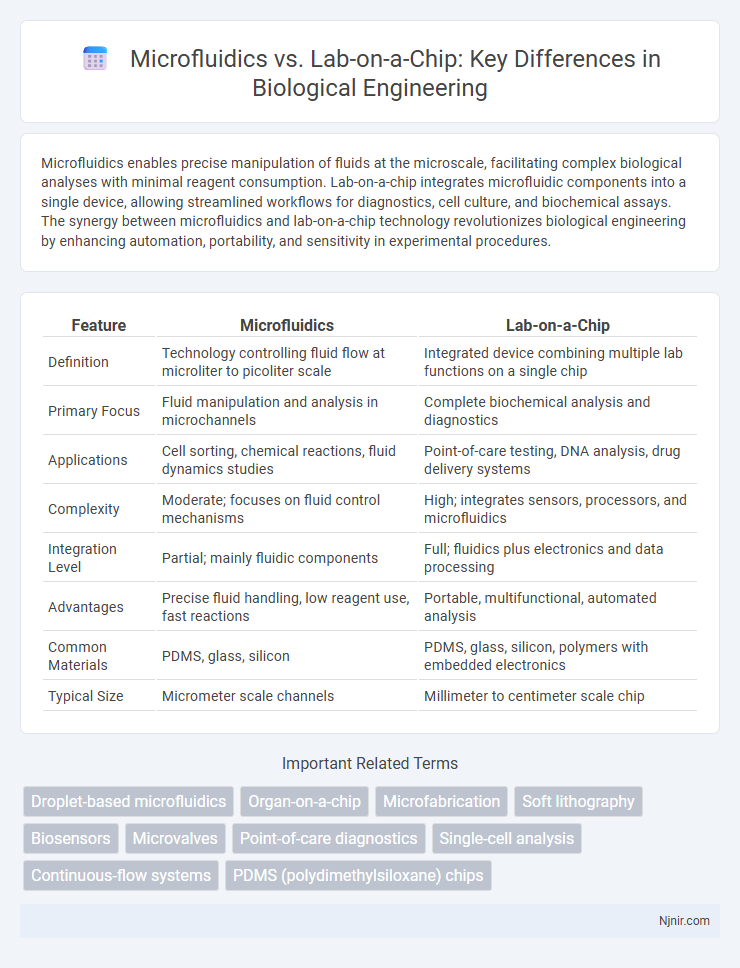

| Feature | Microfluidics | Lab-on-a-Chip |

|---|---|---|

| Definition | Technology controlling fluid flow at microliter to picoliter scale | Integrated device combining multiple lab functions on a single chip |

| Primary Focus | Fluid manipulation and analysis in microchannels | Complete biochemical analysis and diagnostics |

| Applications | Cell sorting, chemical reactions, fluid dynamics studies | Point-of-care testing, DNA analysis, drug delivery systems |

| Complexity | Moderate; focuses on fluid control mechanisms | High; integrates sensors, processors, and microfluidics |

| Integration Level | Partial; mainly fluidic components | Full; fluidics plus electronics and data processing |

| Advantages | Precise fluid handling, low reagent use, fast reactions | Portable, multifunctional, automated analysis |

| Common Materials | PDMS, glass, silicon | PDMS, glass, silicon, polymers with embedded electronics |

| Typical Size | Micrometer scale channels | Millimeter to centimeter scale chip |

Introduction to Microfluidics and Lab-on-a-Chip

Microfluidics involves the manipulation of fluids at the microscale to enable precise control of chemical and biological processes within channels smaller than a human hair. Lab-on-a-chip technology integrates multiple laboratory functions onto a single microfluidic chip, allowing for rapid, automated analysis with minimal sample volumes. This convergence enhances diagnostic capabilities in medical, environmental, and chemical applications by reducing costs and increasing throughput.

Fundamental Principles of Microfluidics

Microfluidics involves the manipulation of fluids at the microscale, utilizing principles such as laminar flow, surface tension, and diffusion to precisely control fluid behavior within channels often less than 100 micrometers in diameter. Lab-on-a-chip integrates microfluidic components to perform complex laboratory functions on a single chip, leveraging microscale device fabrication techniques and fluid dynamics for rapid biochemical analysis. Understanding microfluidic fundamentals like capillary action and electrokinetic effects enables optimization of lab-on-a-chip applications in diagnostics, drug development, and environmental monitoring.

Core Components of Lab-on-a-Chip Technology

Microfluidics involves the precise control and manipulation of fluids at the microscale, forming the foundation for lab-on-a-chip technology. Core components of lab-on-a-chip systems include microchannels for fluid transport, microvalves and micropumps for flow regulation, and integrated sensors for real-time detection and analysis. These miniaturized components enable complex biochemical assays and diagnostics within a compact platform, enhancing efficiency and reducing sample volumes.

Comparative Overview: Functionality and Design

Microfluidics involves the manipulation of fluids at the microscale to analyze and control chemical and biological processes, whereas lab-on-a-chip integrates multiple laboratory functions on a single chip to perform complex analyses efficiently. Microfluidics emphasizes precise fluid dynamics and channel design for applications like drug delivery and diagnostics, while lab-on-a-chip combines components such as sensors, pumps, and valves for automated sample processing. Both technologies enhance miniaturization and portability, but lab-on-a-chip devices offer broader functionality by integrating diverse analytical steps into a unified platform.

Material Selection: Microfluidics vs Lab-on-a-Chip

Material selection in microfluidics revolves around substrates such as glass, silicon, and polymers like PDMS due to their chemical compatibility, optical transparency, and ease of fabrication. Lab-on-a-chip devices prioritize biocompatible and flexible materials including thermoplastics and hydrogels to support integrated biological assays and mass production scalability. Differences in mechanical properties and surface chemistry between these materials significantly influence device performance, fluid dynamics, and application-specific functionality.

Applications in Biological Engineering

Microfluidics technology enables precise control and manipulation of fluids at the microscale, facilitating high-throughput screening, single-cell analysis, and biomarker detection in biological engineering. Lab-on-a-chip integrates microfluidic components into compact devices that automate complex laboratory processes, revolutionizing point-of-care diagnostics, drug development, and tissue engineering applications. Both technologies enhance experimental accuracy and reduce reagent costs while accelerating biological research and clinical testing workflows.

Fabrication Techniques and Scalability

Microfluidics fabrication techniques include soft lithography, photolithography, and injection molding, enabling precise control over microscale fluid channels suitable for prototyping and research applications. Lab-on-a-chip devices utilize similar fabrication methods but often incorporate advanced materials like PDMS, glass, and silicon to integrate multiple laboratory functions on a single chip, enhancing functionality and miniaturization. Scalability challenges in microfluidics arise from complex fabrication steps and material costs, whereas lab-on-a-chip platforms focus on mass production through automated manufacturing processes to enable widespread clinical and commercial use.

Advantages and Limitations of Each Approach

Microfluidics offers precise control of small fluid volumes, enabling high-throughput screening and reduced reagent consumption, but its complexity and fabrication costs can limit widespread adoption. Lab-on-a-chip devices integrate multiple laboratory functions on a single micro-scale chip, providing portability, faster analysis, and automation, yet they often face challenges in scalability and limited versatility for diverse applications. Both technologies complement each other, with microfluidics excelling in fluid manipulation and lab-on-a-chip focusing on system integration for point-of-care diagnostics.

Integration with Biosensing and Diagnostics

Microfluidics enables precise manipulation of fluids at the microscale, enhancing sensitivity and throughput in biosensing applications. Lab-on-a-chip platforms integrate microfluidic channels with biosensors, enabling real-time diagnostics through miniaturized, automated workflows. This integration facilitates rapid detection of biomarkers with high accuracy, transforming point-of-care testing and personalized medicine.

Future Trends and Innovations in Microfluidic Platforms

Future trends in microfluidic platforms emphasize integration of AI-driven data analysis and advanced materials for enhanced sensitivity and multiplexing capabilities. Innovations are steering towards fully automated, portable lab-on-a-chip devices enabling real-time diagnostics and personalized medicine. Emerging technologies such as 3D printing and nanofabrication are driving cost-effective production and customization of microfluidic systems.

Droplet-based microfluidics

Droplet-based microfluidics enables precise manipulation of discrete fluid volumes within Lab-on-a-chip devices, enhancing high-throughput biochemical assays and single-cell analysis with increased control and scalability.

Organ-on-a-chip

Organ-on-a-chip technology leverages microfluidics within lab-on-a-chip platforms to replicate organ-level functions for advanced biomedical research and drug testing.

Microfabrication

Microfabrication techniques such as photolithography and soft lithography enable the precise construction of microfluidic devices, distinguishing microfluidics from more integrated lab-on-a-chip systems by focusing on channel and component fabrication at the microscale.

Soft lithography

Soft lithography enables precise microfluidic device fabrication by using elastomeric molds, making it a preferred technique for developing compact, efficient lab-on-a-chip systems with complex channel architectures.

Biosensors

Microfluidics enables precise fluid manipulation at the microscale, enhancing biosensor sensitivity and integration in lab-on-a-chip devices for rapid, multiplexed biomedical diagnostics.

Microvalves

Microvalves in microfluidics precisely control fluid flow by enabling on-chip regulation, improving the functionality and integration of lab-on-a-chip systems for biomedical and chemical applications.

Point-of-care diagnostics

Microfluidics enhances point-of-care diagnostics by enabling precise fluid manipulation on lab-on-a-chip devices, which integrate multiple laboratory functions for rapid, portable, and cost-effective disease detection.

Single-cell analysis

Microfluidics enables precise manipulation of fluids on a microscale, while lab-on-a-chip integrates multiple microfluidic functions into a compact platform for high-throughput single-cell analysis.

Continuous-flow systems

Continuous-flow microfluidic systems enable precise fluid manipulation in lab-on-a-chip devices, enhancing analytical throughput and integration for biomedical and chemical applications.

PDMS (polydimethylsiloxane) chips

PDMS chips in microfluidics offer flexible, biocompatible platforms for fabricating lab-on-a-chip devices that enable precise fluid control and integration of complex biochemical assays in miniaturized formats.

Microfluidics vs Lab-on-a-chip Infographic

njnir.com

njnir.com