Bioreactor culture offers precise control over environmental conditions such as pH, temperature, and oxygen levels, enhancing cell growth and product consistency compared to suspension culture. Suspension culture provides a simpler, scalable method for growing cells in liquid media but often lacks the uniformity and efficiency achieved in bioreactors. Optimizing culture methods in biological engineering is crucial for maximizing yield and ensuring reproducibility in biopharmaceutical production.

Table of Comparison

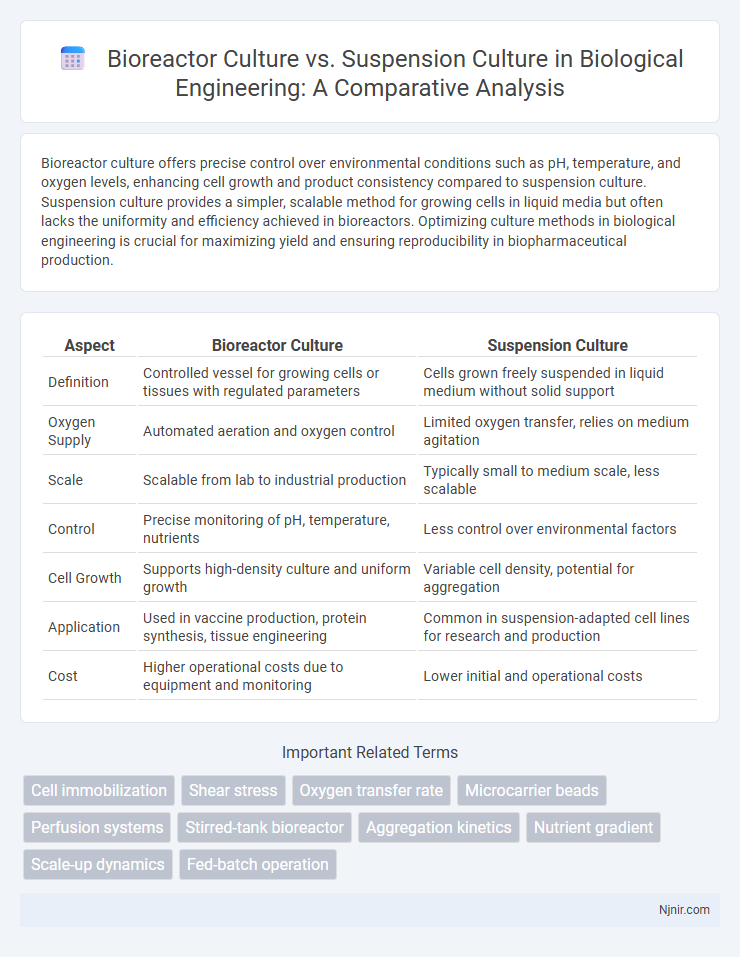

| Aspect | Bioreactor Culture | Suspension Culture |

|---|---|---|

| Definition | Controlled vessel for growing cells or tissues with regulated parameters | Cells grown freely suspended in liquid medium without solid support |

| Oxygen Supply | Automated aeration and oxygen control | Limited oxygen transfer, relies on medium agitation |

| Scale | Scalable from lab to industrial production | Typically small to medium scale, less scalable |

| Control | Precise monitoring of pH, temperature, nutrients | Less control over environmental factors |

| Cell Growth | Supports high-density culture and uniform growth | Variable cell density, potential for aggregation |

| Application | Used in vaccine production, protein synthesis, tissue engineering | Common in suspension-adapted cell lines for research and production |

| Cost | Higher operational costs due to equipment and monitoring | Lower initial and operational costs |

Introduction to Bioreactor and Suspension Cultures

Bioreactor culture involves the controlled growth of cells or microorganisms within a vessel designed to maintain optimal conditions such as pH, temperature, and oxygen levels for large-scale production. Suspension culture refers to a cell cultivation method where cells are grown freely suspended in a liquid medium, commonly used for cell lines that do not adhere to surfaces. Both methods play crucial roles in biotechnology applications, with bioreactors enabling scalable, automated processes and suspension cultures providing efficient growth environments for various cell types.

Principles of Bioreactor Culture Systems

Bioreactor culture systems operate on controlled environmental parameters such as temperature, pH, dissolved oxygen, and nutrient supply to optimize cell growth and product formation. These systems employ mixing and aeration mechanisms to maintain homogeneity and enhance mass transfer, ensuring uniform exposure of suspended cells or tissues to nutrients and gases. In contrast to static suspension cultures, bioreactors provide scalable, monitored, and reproducible conditions critical for industrial bioprocessing applications.

Fundamentals of Suspension Culture Techniques

Suspension culture techniques involve growing cells freely suspended in a liquid medium, allowing efficient nutrient distribution and gas exchange essential for high cell density and rapid proliferation. Fundamental aspects include maintaining optimal agitation speed to prevent cell damage while ensuring homogenous mixing, and controlling pH, temperature, and dissolved oxygen levels to support cell viability and productivity. Unlike bioreactor cultures that may use immobilization or microcarrier systems, suspension cultures emphasize shear force management and scalability for large-scale cell production in biotech applications.

Comparison of Growth Environments

Bioreactor culture offers a controlled environment with precise regulation of parameters like pH, temperature, dissolved oxygen, and nutrient supply, enabling optimal cell growth and metabolite production. Suspension culture allows free-floating cells in liquid media but lacks the uniform control over environmental factors compared to bioreactors. This difference affects cell density, growth rate, and product consistency, with bioreactors providing more scalable and reproducible conditions for large-scale production.

Cell Density and Productivity Analysis

Bioreactor culture enables higher cell density by providing controlled environmental parameters such as oxygen, pH, and nutrient supply, leading to enhanced cell growth compared to suspension culture. Suspension culture often faces limitations in oxygen transfer and shear stress, resulting in lower cell density and productivity. Productivity analysis shows bioreactors yield increased biomass and metabolite production due to optimized conditions, making them preferable for large-scale bioprocessing.

Scalability and Process Optimization

Bioreactor culture offers superior scalability for large-scale cell growth by providing precise control over environmental parameters such as pH, temperature, and oxygen levels, enabling consistent and reproducible results. Suspension culture facilitates efficient nutrient and gas exchange through constant agitation, making it ideal for scaling up processes involving cells or microorganisms in liquid media. Process optimization in bioreactors involves real-time monitoring and automation to maximize yield and viability, whereas suspension cultures rely on optimized agitation rates and media composition to enhance cell proliferation and product quality.

Contamination Risks and Sterility Management

Bioreactor culture offers enhanced control over contamination risks through closed systems, precise monitoring, and automated sterilization processes, reducing the likelihood of microbial invasion compared to suspension culture. Suspension culture, often performed in open or semi-closed systems, presents higher sterility management challenges due to frequent manual handling and increased exposure to contaminants. Implementing rigorous aseptic techniques and real-time contamination detection is critical for maintaining sterility in both culture methods, but bioreactors provide superior containment and environmental regulation.

Cost Efficiency and Resource Utilization

Bioreactor culture offers enhanced cost efficiency through precise control of environmental conditions, leading to higher cell densities and consistent product yield compared to suspension culture. It optimizes resource utilization by enabling automated monitoring and reduced reagent consumption, minimizing waste and operational labor. Suspension culture, while simpler and less capital-intensive initially, typically demands greater volumes of media and manual intervention, increasing long-term operational costs.

Applications in Industrial and Pharmaceutical Biotechnology

Bioreactor culture enables precise control over environmental parameters such as pH, temperature, and oxygen levels, making it ideal for large-scale production of pharmaceuticals like monoclonal antibodies and vaccines. Suspension culture is widely used for cultivating microbial and mammalian cells in industrial biotechnology, facilitating efficient biomass growth and metabolite production. Both methods are integral to biotechnological applications, with bioreactors offering scalability and suspension cultures providing flexibility for various cell types and product yields.

Future Trends in Cell Culture Technologies

Future trends in cell culture technologies highlight bioreactor culture's scalability and precise environmental control as key advantages over suspension culture, enabling high-density cell growth and consistent product quality. Integration of automation, real-time monitoring, and AI-driven analytics in bioreactor systems enhances process optimization and reproducibility. Advances in single-use bioreactors and perfusion culture methods are expected to further improve efficiency and reduce contamination risks in industrial bioproduction.

Cell immobilization

Bioreactor culture enhances cell immobilization by providing controlled environments for fixed-cell growth, whereas suspension culture supports free-floating cells without structural anchorage.

Shear stress

Bioreactor culture typically imposes higher shear stress on cells compared to suspension culture, significantly affecting cell viability and productivity in bioprocessing.

Oxygen transfer rate

Bioreactor culture achieves significantly higher oxygen transfer rates (OTR) due to controlled agitation and aeration compared to suspension culture, enhancing cell growth and productivity.

Microcarrier beads

Microcarrier beads enhance cell growth in bioreactor culture by providing a large surface area for anchorage-dependent cells, unlike suspension culture which lacks solid substrates for cell attachment.

Perfusion systems

Perfusion bioreactor systems enhance cell density and product yield in suspension cultures by continuously supplying fresh media and removing waste, optimizing nutrient availability and metabolic waste removal.

Stirred-tank bioreactor

Stirred-tank bioreactors provide enhanced oxygen transfer, precise pH control, and scalable agitation for suspension cultures, improving cell growth and productivity compared to traditional static suspension methods.

Aggregation kinetics

Bioreactor culture demonstrates controlled aggregation kinetics with uniform cell cluster formation, whereas suspension culture often results in heterogeneous aggregation rates and variable cluster sizes.

Nutrient gradient

Bioreactor culture maintains a controlled nutrient gradient ensuring uniform cell growth, while suspension culture often experiences uneven nutrient distribution leading to variable cell viability.

Scale-up dynamics

Bioreactor culture enables precise control and scalability of environmental parameters for efficient large-scale cell growth, whereas suspension culture offers simpler scaling but with less uniformity and control, impacting overall scale-up dynamics.

Fed-batch operation

Fed-batch operation in bioreactor culture enables controlled nutrient addition for higher cell density and productivity compared to traditional suspension culture.

Bioreactor culture vs Suspension culture Infographic

njnir.com

njnir.com