BioMEMS and NanoMEMS both revolutionize biomedical engineering by enabling precise manipulation at micro and nanoscale, respectively. BioMEMS primarily integrate biological elements with microelectromechanical systems for applications like drug delivery and biosensing. NanoMEMS push these capabilities further by operating at nanometer dimensions, enhancing sensitivity and functionality in diagnostics and cellular-level interactions.

Table of Comparison

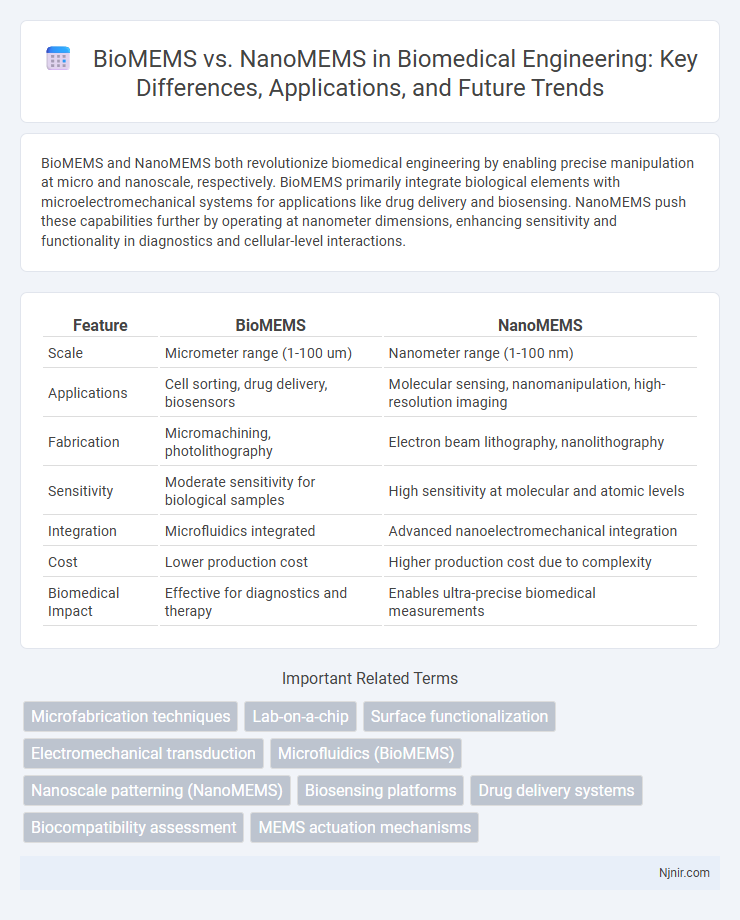

| Feature | BioMEMS | NanoMEMS |

|---|---|---|

| Scale | Micrometer range (1-100 um) | Nanometer range (1-100 nm) |

| Applications | Cell sorting, drug delivery, biosensors | Molecular sensing, nanomanipulation, high-resolution imaging |

| Fabrication | Micromachining, photolithography | Electron beam lithography, nanolithography |

| Sensitivity | Moderate sensitivity for biological samples | High sensitivity at molecular and atomic levels |

| Integration | Microfluidics integrated | Advanced nanoelectromechanical integration |

| Cost | Lower production cost | Higher production cost due to complexity |

| Biomedical Impact | Effective for diagnostics and therapy | Enables ultra-precise biomedical measurements |

Introduction to BioMEMS and NanoMEMS

BioMEMS (Biomedical Microelectromechanical Systems) integrates microscale devices with biological and medical applications, enabling advancements in diagnostics, drug delivery, and tissue engineering. NanoMEMS extends this technology to the nanoscale, offering enhanced sensitivity and precision for biomolecular sensing and nanoscale manipulation in medical research. Both BioMEMS and NanoMEMS leverage micro/nanofabrication techniques to develop innovative tools for healthcare and biotechnology.

Fundamental Differences between BioMEMS and NanoMEMS

BioMEMS integrate biological components with microelectromechanical systems for applications like medical diagnostics and drug delivery, emphasizing biocompatibility and fluidic control at the microscale. NanoMEMS operate at a smaller scale, incorporating nanotechnology to achieve higher sensitivity and precision in sensing and actuation, often targeting molecular or atomic-level interactions. The fundamental difference lies in scale and application focus: BioMEMS prioritize interaction with biological environments, while NanoMEMS leverage nanoscale features for enhanced performance in diverse technological fields.

Fabrication Techniques: Micro vs. Nano Scale

Fabrication techniques for BioMEMS typically utilize photolithography and bulk micromachining to create micro-scale structures compatible with biological environments, emphasizing biocompatibility and fluid control. NanoMEMS leverage advanced nanofabrication processes such as electron beam lithography, nanoimprint lithography, and atomic layer deposition to achieve nano-scale precision and feature sizes below 100 nanometers. The transition from micro to nano scale involves challenges in process control, material selection, and integration, enabling higher sensitivity and novel functionalities in NanoMEMS devices.

Material Selection in BioMEMS and NanoMEMS

Material selection in BioMEMS primarily involves biocompatible substances such as silicon, polymers like PDMS, and hydrogels to ensure safe interaction with biological tissues. NanoMEMS require materials with superior mechanical strength and electrical properties, including silicon nanowires, graphene, and carbon nanotubes, to achieve high precision at the nanoscale. Both fields emphasize material stability and functionality, but BioMEMS prioritize bio-integration while NanoMEMS focus on nanoscale performance and sensitivity.

Key Applications in Biomedical Engineering

BioMEMS devices excel in applications such as implantable sensors, drug delivery systems, and tissue engineering scaffolds due to their compatibility with biological environments. NanoMEMS technology enhances precision in single-cell analysis, neural interfaces, and molecular diagnostics by leveraging nanoscale fabrication techniques. Both platforms revolutionize biomedical engineering through improved sensitivity and integration in disease monitoring and personalized medicine.

Sensitivity and Precision: Nano vs. Micro Devices

NanoMEMS devices exhibit significantly higher sensitivity and precision compared to BioMEMS due to their smaller scale, allowing for detection of molecular and atomic-level interactions. The reduced size of NanoMEMS enhances their resolution and response time, making them ideal for applications requiring ultra-fine measurements, such as single-cell analysis and nanoscale chemical detection. In contrast, BioMEMS typically operate at the microscale, balancing sensitivity with robustness for biological environments but with lower spatial resolution and slower response than nano-scale counterparts.

Integration with Biological Systems

BioMEMS leverage microscale structures for seamless integration with biological tissues, enabling precise monitoring and interaction at the cellular level. NanoMEMS operate at a smaller scale, offering enhanced sensitivity and specificity for detecting molecular and nanoscale biological phenomena. Both technologies are pivotal for advanced biomedical applications, with NanoMEMS providing superior resolution for single-molecule analysis and BioMEMS excelling in tissue-level interfacing.

Challenges in Scalability and Manufacturability

BioMEMS face challenges in scalability due to biological material compatibility and the need for sterile, biocompatible environments, which complicate mass production. NanoMEMS encounter difficulties in manufacturability from the precision required at the nanoscale, including issues with lithography limits and defect control during fabrication. Both technologies struggle with integrating complex systems while maintaining cost-effectiveness and high yield in large-volume manufacturing.

Regulatory and Ethical Considerations

BioMEMS devices, designed for biological and medical applications, face stringent regulatory scrutiny due to their direct interaction with human tissues and fluids, requiring compliance with FDA or EMA guidelines focused on safety and biocompatibility. NanoMEMS, operating at the nanoscale, present unique ethical concerns related to potential toxicity, long-term environmental impact, and privacy issues in wearable or implantable technologies. Regulatory frameworks for NanoMEMS are evolving to address challenges in nanoparticle behavior, reproducibility, and risk assessment, emphasizing the need for comprehensive ethical evaluation and transparent clinical validation.

Future Prospects in Biomedical Engineering

BioMEMS leverage micro-scale technologies for applications such as implantable sensors and lab-on-a-chip devices, offering promising advances in minimally invasive diagnostics and targeted drug delivery. NanoMEMS further miniaturize these systems to the nanoscale, enabling enhanced sensitivity, molecular-level manipulation, and integration with cellular processes for personalized medicine. The future of biomedical engineering will increasingly depend on NanoMEMS to revolutionize real-time health monitoring, precision therapeutics, and regenerative medicine through their superior spatial resolution and functional versatility.

Microfabrication techniques

BioMEMS primarily utilize conventional photolithography and micromachining for microfabrication, while NanoMEMS require advanced techniques such as electron beam lithography and atomic layer deposition to achieve nanoscale precision.

Lab-on-a-chip

BioMEMS integrate microscale biological components for Lab-on-a-chip applications enabling precise biochemical analysis, while NanoMEMS leverage nanoscale features to enhance sensitivity and functionality in miniaturized Lab-on-a-chip devices.

Surface functionalization

Surface functionalization in BioMEMS leverages biomolecular coatings for enhanced biocompatibility and specificity, while NanoMEMS employs atomic-scale modifications to achieve superior sensitivity and precise molecular interactions.

Electromechanical transduction

BioMEMS utilize microscale electromechanical transduction for biomedical sensing and actuation, whereas NanoMEMS leverage nanoscale transduction mechanisms to achieve higher sensitivity and precision in detecting molecular and cellular interactions.

Microfluidics (BioMEMS)

BioMEMS leverage microfluidics to enable precise manipulation of biological fluids at the microscale for applications in diagnostics, drug delivery, and tissue engineering, while NanoMEMS operate at the nanoscale for enhanced sensitivity but with limited fluidic control.

Nanoscale patterning (NanoMEMS)

NanoMEMS utilize advanced nanoscale patterning techniques to achieve higher precision and functionality compared to traditional BioMEMS, enabling superior performance in applications requiring molecular-level manipulation.

Biosensing platforms

BioMEMS biosensing platforms leverage microscale sensors for biological detection, while NanoMEMS enhance sensitivity and resolution by utilizing nanoscale structures for improved biomolecular interaction and signal transduction.

Drug delivery systems

NanoMEMS enable more precise drug delivery systems than BioMEMS by leveraging nanoscale features for targeted cellular interaction and controlled release kinetics.

Biocompatibility assessment

BioMEMS demonstrate superior biocompatibility in medical applications due to their microscale design tailored for biological environments, whereas NanoMEMS require enhanced surface modifications to mitigate potential cytotoxicity at the nanoscale.

MEMS actuation mechanisms

BioMEMS primarily utilize micro-scale electrostatic and piezoelectric actuators for precise biofluid control, whereas NanoMEMS rely on advanced nanoelectromechanical actuation mechanisms such as electron tunneling and quantum confinement effects for ultra-sensitive manipulation.

BioMEMS vs NanoMEMS Infographic

njnir.com

njnir.com