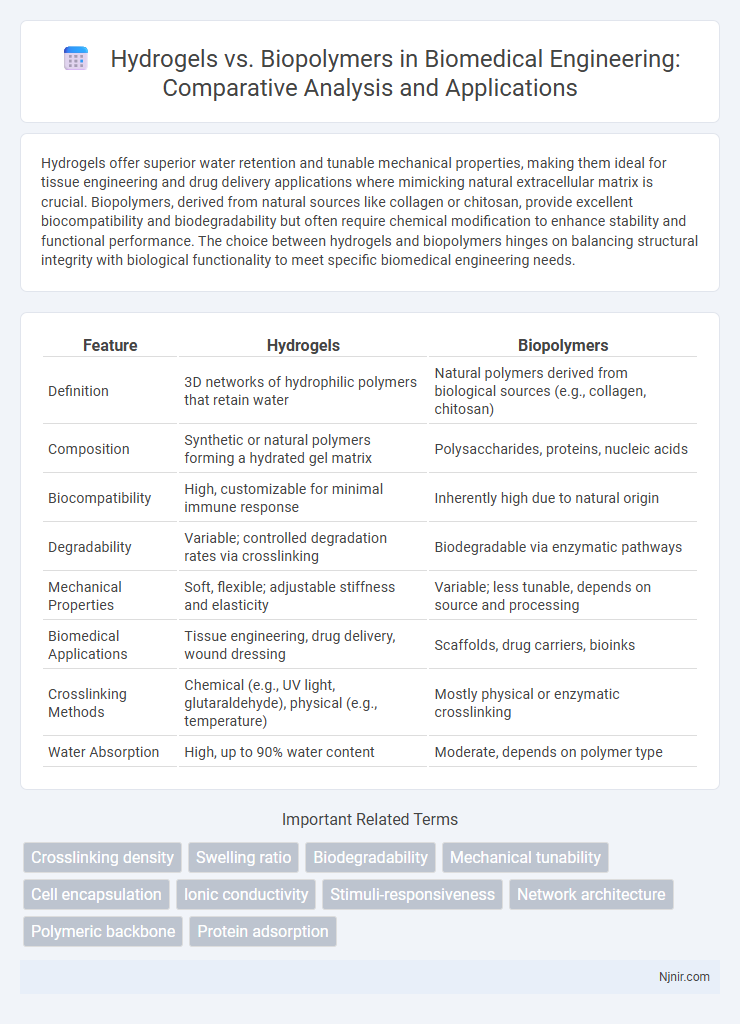

Hydrogels offer superior water retention and tunable mechanical properties, making them ideal for tissue engineering and drug delivery applications where mimicking natural extracellular matrix is crucial. Biopolymers, derived from natural sources like collagen or chitosan, provide excellent biocompatibility and biodegradability but often require chemical modification to enhance stability and functional performance. The choice between hydrogels and biopolymers hinges on balancing structural integrity with biological functionality to meet specific biomedical engineering needs.

Table of Comparison

| Feature | Hydrogels | Biopolymers |

|---|---|---|

| Definition | 3D networks of hydrophilic polymers that retain water | Natural polymers derived from biological sources (e.g., collagen, chitosan) |

| Composition | Synthetic or natural polymers forming a hydrated gel matrix | Polysaccharides, proteins, nucleic acids |

| Biocompatibility | High, customizable for minimal immune response | Inherently high due to natural origin |

| Degradability | Variable; controlled degradation rates via crosslinking | Biodegradable via enzymatic pathways |

| Mechanical Properties | Soft, flexible; adjustable stiffness and elasticity | Variable; less tunable, depends on source and processing |

| Biomedical Applications | Tissue engineering, drug delivery, wound dressing | Scaffolds, drug carriers, bioinks |

| Crosslinking Methods | Chemical (e.g., UV light, glutaraldehyde), physical (e.g., temperature) | Mostly physical or enzymatic crosslinking |

| Water Absorption | High, up to 90% water content | Moderate, depends on polymer type |

Introduction to Hydrogels and Biopolymers

Hydrogels are three-dimensional networks of hydrophilic polymers capable of retaining large amounts of water, making them ideal for applications in drug delivery, tissue engineering, and wound healing. Biopolymers, derived from natural sources such as proteins, polysaccharides, and nucleic acids, exhibit biocompatibility and biodegradability, which are essential for sustainable medical and environmental uses. Both hydrogels and biopolymers play critical roles in advancing biomedical technology by providing versatile materials that mimic biological tissues.

Chemical Structure and Composition Comparison

Hydrogels consist primarily of hydrophilic polymer networks capable of retaining large amounts of water, often synthesized from synthetic polymers like polyacrylamide or naturally derived biopolymers such as alginate and chitosan. Biopolymers, including proteins like collagen and polysaccharides like cellulose, exhibit diverse chemical structures ranging from linear to branched macromolecules with varying functional groups that influence biodegradability and bioactivity. The key difference lies in hydrogels' three-dimensional crosslinked network designed for swelling, while biopolymers present varied molecular architectures often tailored for specific biological functions.

Mechanical Properties and Biocompatibility

Hydrogels exhibit tunable mechanical properties ranging from soft and flexible to more rigid structures, making them suitable for applications requiring tissue-like elasticity, while biopolymers generally offer moderate mechanical strength with enhanced biodegradability. Both hydrogels and biopolymers demonstrate high biocompatibility due to their ability to mimic natural extracellular matrices, supporting cellular adhesion and proliferation. Advances in crosslinking techniques improve hydrogel mechanical stability without compromising biocompatibility, whereas biopolymer composites often incorporate reinforcing agents to enhance mechanical resilience for biomedical uses.

Synthesis and Fabrication Techniques

Hydrogels are typically synthesized through chemical or physical crosslinking methods involving monomers like acrylamide or natural polymers such as alginate, enabling tailored swelling and mechanical properties. Biopolymers, derived from renewable sources like cellulose, chitosan, or gelatin, are fabricated using techniques including electrospinning, solvent casting, and 3D bioprinting to create scaffolds with controlled porosity and bioactivity. Advanced fabrication approaches such as freeze-drying and microfluidic-assisted synthesis enhance the structural integrity and functionality of both hydrogels and biopolymers for biomedical and environmental applications.

Degradation and Biodegradability Profiles

Hydrogels typically exhibit controlled degradation rates influenced by their crosslinking density and polymer composition, enabling tailored biodegradability for biomedical applications. Biopolymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) generally present inherent biodegradability through enzymatic hydrolysis and microbial activity, leading to environmentally friendly breakdown products. The degradation profiles of hydrogels often involve hydrolytic or enzymatic mechanisms, whereas biopolymers predominantly rely on microbial degradation pathways in natural environments.

Applications in Drug Delivery Systems

Hydrogels exhibit superior drug delivery capabilities due to their high water content and tunable porosity, allowing controlled release and targeted therapy in wound healing and cancer treatment. Biopolymers like chitosan and alginate offer biocompatibility and biodegradability, making them ideal carriers for sustained drug release and tissue engineering applications. Combining hydrogels with biopolymers enhances mechanical strength and responsiveness to physiological stimuli, optimizing therapeutic efficacy in advanced drug delivery systems.

Tissue Engineering and Regenerative Medicine

Hydrogels and biopolymers serve crucial roles in tissue engineering and regenerative medicine by providing biocompatible scaffolds that mimic the extracellular matrix, promoting cell adhesion, proliferation, and differentiation. Hydrogels, with their high water content and tunable mechanical properties, facilitate nutrient diffusion and waste removal essential for tissue regeneration, while biopolymers like collagen, chitosan, and alginate offer natural biochemical cues that enhance tissue integration and repair. Combining hydrogels with biopolymers leverages their complementary properties, improving scaffold functionality, mechanical strength, and controlled bioactive molecule delivery to support complex tissue regeneration.

Challenges in Clinical Translation

Hydrogels face clinical translation challenges such as controlling biodegradability and ensuring consistent mechanical properties under physiological conditions. Biopolymers encounter limitations including potential immunogenicity and variability in source materials that affect reproducibility. Both materials require stringent regulatory approval processes and standardized manufacturing techniques to achieve clinical viability.

Cost, Scalability, and Manufacturing Considerations

Hydrogels typically offer lower production costs due to simpler cross-linking processes compared to biopolymers, which often require more complex extraction and purification methods. Scalability for hydrogels is generally more feasible in industrial settings, leveraging established synthetic polymer manufacturing infrastructure, while biopolymers face challenges in consistent raw material supply and batch variability. Manufacturing considerations highlight hydrogels' advantage in controlled chemical synthesis and reproducibility, whereas biopolymer production must address biodegradability and biocompatibility standards, impacting cost and process optimization.

Future Trends and Innovations

Hydrogels, known for their exceptional water retention and biocompatibility, are advancing with innovations in stimuli-responsive and smart drug delivery systems, enhancing targeted therapy and regenerative medicine. Biopolymers, derived from renewable resources, are witnessing future trends in sustainable packaging and biodegradable medical implants, driven by environmental concerns and regulatory pressures. Integration of nanotechnology with hydrogels and biopolymers is fostering next-generation composites that exhibit improved mechanical strength, controlled degradation, and multifunctionality for diverse biomedical applications.

Crosslinking density

Hydrogels typically exhibit higher crosslinking density than biopolymers, enhancing their mechanical strength and swelling control for biomedical applications.

Swelling ratio

Hydrogels typically exhibit a higher swelling ratio than biopolymers due to their crosslinked hydrophilic network structure that enables greater water absorption and retention.

Biodegradability

Biopolymers exhibit superior biodegradability compared to hydrogels, making them more environmentally sustainable for medical and packaging applications.

Mechanical tunability

Hydrogels exhibit superior mechanical tunability compared to biopolymers, enabling customizable stiffness and elasticity for diverse biomedical and engineering applications.

Cell encapsulation

Hydrogels provide a highly hydrated, biocompatible matrix with tunable mechanical properties ideal for cell encapsulation, while biopolymers offer natural extracellular matrix components that enhance cell adhesion and functional differentiation.

Ionic conductivity

Hydrogels exhibit higher ionic conductivity than traditional biopolymers due to their enhanced water retention and cross-linked polymer networks facilitating ion transport.

Stimuli-responsiveness

Hydrogels exhibit superior stimuli-responsiveness compared to biopolymers, dynamically altering their physical properties in response to environmental triggers such as pH, temperature, and light, making them ideal for advanced drug delivery and tissue engineering applications.

Network architecture

Hydrogels exhibit a three-dimensional crosslinked polymer network providing high water retention and mechanical strength, whereas biopolymers typically feature linear or branched architectures influencing their biodegradability and biocompatibility.

Polymeric backbone

Hydrogels typically feature a hydrophilic polymeric backbone that enables extensive water absorption and swelling, whereas biopolymers possess natural or synthetic polymeric backbones that provide biodegradability and biocompatibility for medical and environmental applications.

Protein adsorption

Hydrogels exhibit controlled protein adsorption due to their hydrophilic networks, while biopolymers offer tunable protein-binding properties driven by their natural molecular structures.

Hydrogels vs Biopolymers Infographic

njnir.com

njnir.com