Disposable microdevices in biomedical engineering offer the advantage of eliminating cross-contamination risks, making them ideal for single-use applications such as point-of-care diagnostics and sterile sampling. Reusable microdevices provide cost-efficiency over time and are designed for durability, often incorporating materials that withstand sterilization processes without compromising function. Selecting between disposable and reusable microdevices depends on factors such as application specificity, contamination control, budget constraints, and operational throughput requirements.

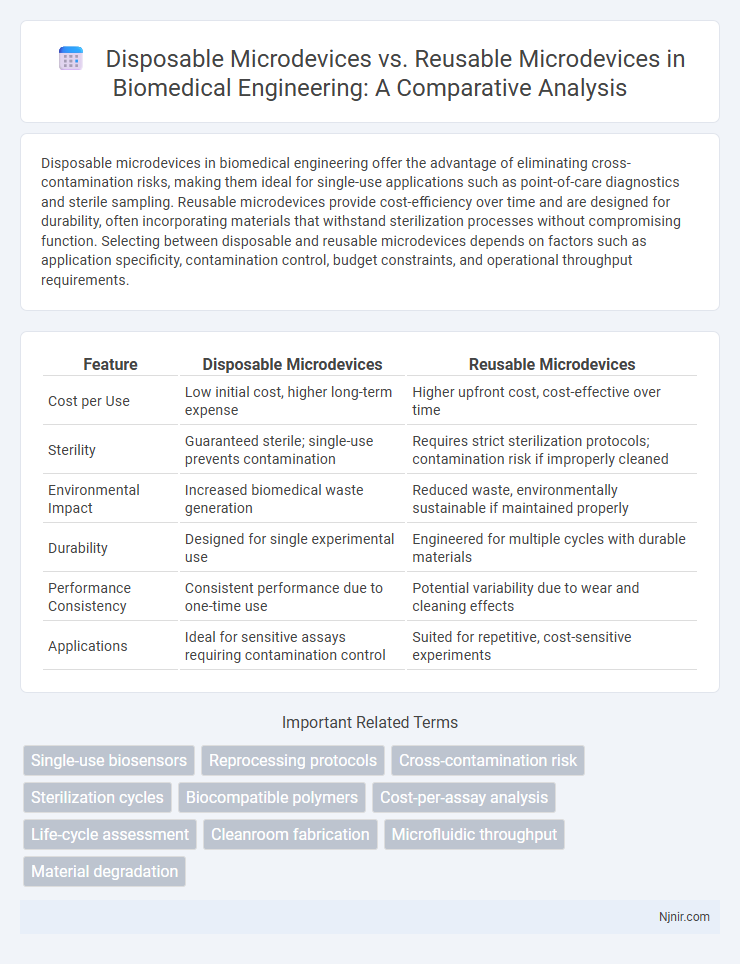

Table of Comparison

| Feature | Disposable Microdevices | Reusable Microdevices |

|---|---|---|

| Cost per Use | Low initial cost, higher long-term expense | Higher upfront cost, cost-effective over time |

| Sterility | Guaranteed sterile; single-use prevents contamination | Requires strict sterilization protocols; contamination risk if improperly cleaned |

| Environmental Impact | Increased biomedical waste generation | Reduced waste, environmentally sustainable if maintained properly |

| Durability | Designed for single experimental use | Engineered for multiple cycles with durable materials |

| Performance Consistency | Consistent performance due to one-time use | Potential variability due to wear and cleaning effects |

| Applications | Ideal for sensitive assays requiring contamination control | Suited for repetitive, cost-sensitive experiments |

Introduction to Microdevices in Biomedical Engineering

Disposable microdevices in biomedical engineering offer single-use applications that reduce contamination risks and enhance patient safety during diagnostic or therapeutic procedures. Reusable microdevices, designed for multiple cycles of use, provide cost efficiency and sustainable resource management but require rigorous sterilization protocols to maintain device integrity and performance. Both types are integral to advancing microfabrication technologies that enable miniaturized, precise biomedical interventions and real-time monitoring.

Overview of Disposable Microdevices

Disposable microdevices offer single-use functionality, ensuring sterility and minimizing cross-contamination risks in medical and analytical applications. These devices are often made from cost-effective materials such as polymer substrates, allowing mass production through techniques like injection molding or soft lithography. Their design emphasizes ease of use, rapid deployment, and elimination of cleaning protocols, making them ideal for point-of-care diagnostics and high-throughput screening.

Overview of Reusable Microdevices

Reusable microdevices offer significant cost efficiency by allowing multiple uses without performance degradation, supported by robust materials like silicon and glass. Their design prioritizes sterilizability and durability, making them ideal for long-term applications in medical diagnostics and environmental monitoring. Advanced cleaning protocols and modular components extend the lifespan while maintaining high precision and reliability in repeated experiments.

Material Selection and Manufacturing Technologies

Disposable microdevices typically utilize cost-effective materials like polymers (PDMS, PMMA) and employ manufacturing technologies such as injection molding and soft lithography to enable mass production with consistent quality. Reusable microdevices often require durable materials like silicon, glass, or metals and rely on precision manufacturing methods like photolithography and microfabrication to ensure structural integrity and resistance to chemical or thermal stresses. Material selection balances biocompatibility, mechanical stability, and cost, while manufacturing technologies are chosen based on scalability, reproducibility, and device lifespan requirements.

Cost Analysis: Disposable vs Reusable Microdevices

Disposable microdevices often incur higher long-term costs due to the need for frequent replacement, especially in high-throughput applications. Reusable microdevices require significant upfront investment and maintenance expenses but offer lower per-use costs over time, making them cost-effective for extended or repeated use. Cost analysis must factor in device lifespan, sterilization processes, and operational downtime to determine overall economic efficiency.

Sterilization and Contamination Control

Disposable microdevices eliminate risks of cross-contamination by being single-use, thereby removing the need for complex sterilization processes. Reusable microdevices require rigorous sterilization protocols such as autoclaving, chemical sterilants, or UV treatment to ensure contamination control while maintaining device integrity. Efficient sterilization methods are critical in reusable devices to prevent biofilm formation and preserve functionality over multiple cycles.

Environmental Impact and Sustainability Considerations

Disposable microdevices generate significant electronic waste, contributing to landfill accumulation and resource depletion due to their single-use nature. Reusable microdevices minimize environmental impact by reducing raw material consumption and waste generation through multiple lifecycles, promoting sustainability. Incorporating recyclable materials and energy-efficient manufacturing processes further enhances the eco-friendly profile of reusable microdevices compared to disposables.

Regulatory and Compliance Challenges

Regulatory and compliance challenges for disposable microdevices primarily involve stringent biocompatibility testing, single-use validation, and waste disposal standards outlined by FDA and ISO. Reusable microdevices require robust sterilization protocols, device durability assessments, and repeated performance validation, complicating compliance with evolving guidelines like the EU MDR. Both categories must address traceability and risk management, but reusable devices face heightened scrutiny due to potential contamination and cumulative wear risks.

Performance and Reliability in Clinical Applications

Disposable microdevices offer consistent, contamination-free performance in clinical applications, ensuring high reliability by eliminating cross-sample variability. Reusable microdevices may experience degradation in sensitivity and accuracy over multiple uses due to material wear and biofouling, potentially compromising clinical outcomes. Optimizing material properties and surface coatings in reusable devices enhances their durability, but disposable microdevices generally provide superior reliability for critical diagnostic procedures.

Future Trends in Microdevice Development

Future trends in microdevice development focus on enhancing sustainability and functionality by integrating advanced materials and intelligent sensors in both disposable and reusable microdevices. Innovations in biodegradable polymers and self-cleaning surfaces aim to reduce environmental impact for disposable devices, while reusable devices are evolving with modular designs and enhanced sterilization techniques to extend their operational lifespan. The convergence of IoT connectivity and miniaturized power sources is driving smarter microdevices capable of real-time data monitoring and adaptive performance across diverse applications.

Single-use biosensors

Single-use biosensors, a category of disposable microdevices, offer enhanced contamination control and cost efficiency compared to reusable microdevices that require sterilization and maintenance.

Reprocessing protocols

Reprocessing protocols for reusable microdevices involve rigorous sterilization and validation steps to ensure safety and functionality, contrasting with disposable microdevices that eliminate reprocessing requirements but generate more medical waste.

Cross-contamination risk

Disposable microdevices significantly reduce cross-contamination risk compared to reusable microdevices by eliminating the need for sterilization between uses.

Sterilization cycles

Reusable microdevices withstand multiple sterilization cycles without degradation, while disposable microdevices are designed for single-use to avoid contamination and eliminate the need for repeated sterilization.

Biocompatible polymers

Disposable microdevices made from biocompatible polymers reduce contamination risks and manufacturing costs, while reusable microdevices require durable, sterilizable polymers to maintain functionality and biocompatibility over multiple uses.

Cost-per-assay analysis

Disposable microdevices typically offer lower upfront costs but higher cost-per-assay due to single-use limitations, whereas reusable microdevices have higher initial investment but reduce long-term cost-per-assay through multiple uses and durability.

Life-cycle assessment

Disposable microdevices often have higher environmental impacts in life-cycle assessments due to single-use waste generation, whereas reusable microdevices reduce waste but require energy and resources for cleaning and maintenance over multiple cycles.

Cleanroom fabrication

Disposable microdevices reduce contamination risks and fabrication costs in cleanroom environments by eliminating cleaning and sterilization processes required for reusable microdevices.

Microfluidic throughput

Disposable microdevices offer high-throughput microfluidic processing with reduced contamination risk, while reusable microdevices provide cost-efficiency and sustainability but may face throughput limitations due to cleaning and maintenance requirements.

Material degradation

Disposable microdevices minimize material degradation risks by using cost-effective, single-use materials, whereas reusable microdevices require durable, corrosion-resistant materials to withstand repeated cleaning and sterilization cycles.

Disposable microdevices vs Reusable microdevices Infographic

njnir.com

njnir.com