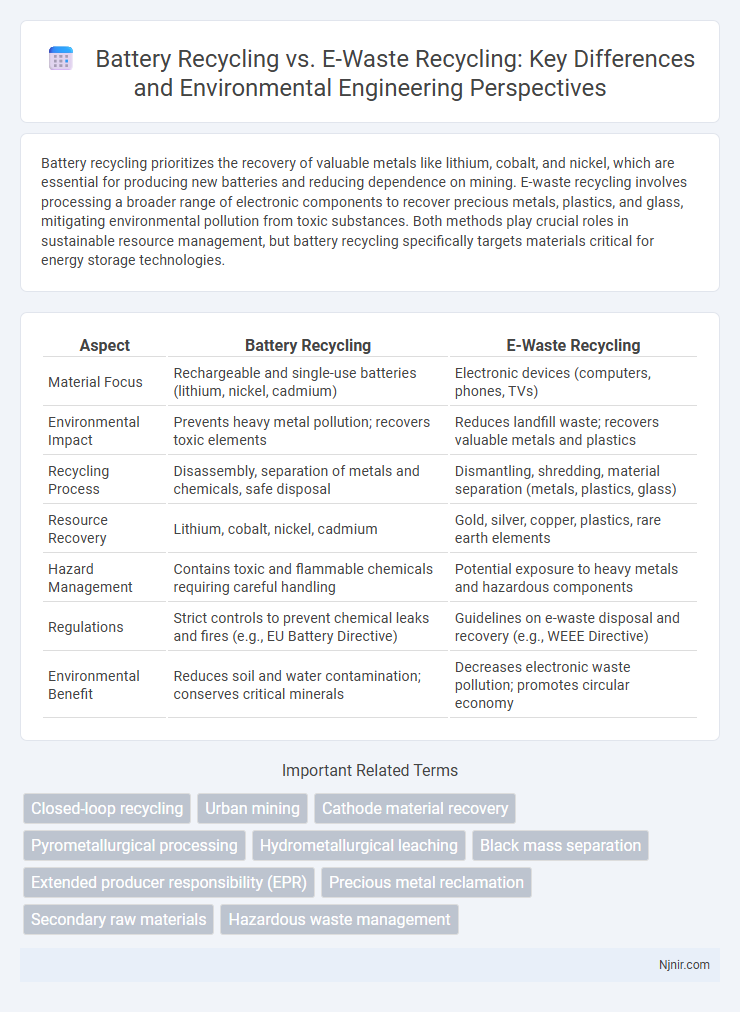

Battery recycling prioritizes the recovery of valuable metals like lithium, cobalt, and nickel, which are essential for producing new batteries and reducing dependence on mining. E-waste recycling involves processing a broader range of electronic components to recover precious metals, plastics, and glass, mitigating environmental pollution from toxic substances. Both methods play crucial roles in sustainable resource management, but battery recycling specifically targets materials critical for energy storage technologies.

Table of Comparison

| Aspect | Battery Recycling | E-Waste Recycling |

|---|---|---|

| Material Focus | Rechargeable and single-use batteries (lithium, nickel, cadmium) | Electronic devices (computers, phones, TVs) |

| Environmental Impact | Prevents heavy metal pollution; recovers toxic elements | Reduces landfill waste; recovers valuable metals and plastics |

| Recycling Process | Disassembly, separation of metals and chemicals, safe disposal | Dismantling, shredding, material separation (metals, plastics, glass) |

| Resource Recovery | Lithium, cobalt, nickel, cadmium | Gold, silver, copper, plastics, rare earth elements |

| Hazard Management | Contains toxic and flammable chemicals requiring careful handling | Potential exposure to heavy metals and hazardous components |

| Regulations | Strict controls to prevent chemical leaks and fires (e.g., EU Battery Directive) | Guidelines on e-waste disposal and recovery (e.g., WEEE Directive) |

| Environmental Benefit | Reduces soil and water contamination; conserves critical minerals | Decreases electronic waste pollution; promotes circular economy |

Introduction to Battery Recycling and E-Waste Recycling

Battery recycling involves the recovery of valuable metals such as lithium, cobalt, and nickel from used batteries, reducing environmental pollution and conserving natural resources. E-waste recycling encompasses the broader process of disassembling and processing discarded electronic devices to extract precious metals, plastics, and glass while safely managing hazardous substances like lead and mercury. Both processes play critical roles in sustainable waste management and resource recovery, addressing the growing volume of electronic and battery waste worldwide.

Environmental Impacts of Battery Waste

Battery recycling significantly reduces environmental hazards by preventing toxic substances like lead, cadmium, and lithium from contaminating soil and water sources, distinct from general e-waste recycling that addresses a broader range of materials. Improper disposal of battery waste leads to the release of heavy metals and corrosive chemicals, causing soil degradation, water pollution, and adverse effects on human health and ecosystems. Specialized battery recycling processes help recover valuable materials while minimizing greenhouse gas emissions and reducing the need for raw material extraction, contributing to a more sustainable circular economy.

Environmental Impacts of E-Waste

E-waste recycling addresses the hazardous components found in electronic devices, such as lead, mercury, and cadmium, which pose significant environmental risks if improperly disposed of. Battery recycling specifically targets the recovery of valuable metals like lithium, cobalt, and nickel, reducing the environmental footprint associated with mining and minimizing toxic leakage into soil and water. Effective e-waste recycling reduces greenhouse gas emissions and mitigates soil and water contamination, proving essential for sustainable resource management and environmental protection.

Key Differences Between Battery and E-Waste Recycling

Battery recycling primarily focuses on recovering valuable metals like lithium, cobalt, and nickel from spent batteries to reduce environmental impact and resource depletion. E-waste recycling involves processing a broader range of electronic components, including circuit boards, plastics, and glass, aiming to safely extract metals such as gold, silver, and copper while managing hazardous substances like lead and mercury. The key difference lies in the specialized techniques and regulatory requirements for handling battery chemistries versus the diverse material composition found in general electronic waste.

Collection and Sorting Processes

Battery recycling involves specialized collection points and stringent sorting processes to separate lithium-ion, nickel-metal hydride, and lead-acid batteries due to their different chemical compositions and hazardous materials. E-waste recycling requires the dismantling of diverse electronic devices to extract valuable metals like gold, copper, and rare earth elements, with sorting often aided by advanced technologies such as automated shredders, magnetic separators, and optical sorters. Efficient collection systems and precise sorting techniques in both battery and e-waste recycling are crucial for maximizing material recovery and minimizing environmental contamination.

Technological Challenges in Recycling

Battery recycling faces significant technological challenges due to the complexity of extracting valuable metals like lithium, cobalt, and nickel from diverse chemistries while ensuring safety and efficiency. E-waste recycling involves separating a wide array of materials including precious metals, plastics, and hazardous substances, requiring advanced automation and chemical processes for effective recovery. Both sectors demand innovation in sorting technology, material recovery techniques, and environmental impact mitigation to overcome current limitations and scale sustainable recycling practices.

Recovery of Valuable Materials

Battery recycling focuses on the efficient recovery of critical materials such as lithium, cobalt, nickel, and manganese, which are essential for manufacturing new batteries and reducing reliance on virgin mining. E-waste recycling targets a broader range of valuable metals including gold, silver, copper, and palladium found in electronic devices, enabling resource conservation and minimizing environmental impact. Advanced processes in both battery and e-waste recycling enhance the extraction rates of precious metals, contributing to sustainable supply chains and circular economy goals.

Regulatory Frameworks and Policies

Battery recycling is governed by specialized regulatory frameworks such as the Battery Directive in the EU and the Resource Conservation and Recovery Act (RCRA) in the US, emphasizing the safe disposal and recovery of hazardous materials like lithium and cadmium. E-waste recycling regulations, like the WEEE Directive in Europe and the Electronic Waste Management Rules in India, encompass a broader range of electronic components and mandate producer responsibility and proper dismantling processes. Both policies aim to minimize environmental impact and promote material recovery but differ in scope, with battery recycling focusing more on hazardous substance management and e-waste regulations addressing overall electronic product lifecycle.

Innovations in Recycling Methods

Innovations in battery recycling now emphasize hydrometallurgical and direct recycling techniques, enabling higher recovery rates of critical metals like lithium, cobalt, and nickel, reducing environmental impact and enhancing resource efficiency. E-waste recycling methods are increasingly integrating advanced AI-driven sorting systems and automated disassembly robots to improve material separation accuracy and reduce human exposure to hazardous components. These technological advancements contribute to more sustainable circular economies by maximizing valuable material recovery and minimizing landfill waste from both batteries and electronic devices.

Future Trends and Sustainability Potential

Battery recycling is evolving with advanced technologies targeting lithium-ion and solid-state batteries, promising higher recovery rates of critical metals like lithium, cobalt, and nickel, essential for electric vehicles and renewable energy storage. E-waste recycling encompasses a broader spectrum, focusing on recovering precious metals such as gold, silver, and palladium from discarded electronics, but faces challenges with complex material separation and hazardous substances. Future trends highlight integration of AI-driven sorting and circular economy models that maximize resource recovery, reduce environmental impact, and promote sustainable supply chains across both battery and e-waste recycling sectors.

Closed-loop recycling

Closed-loop battery recycling enables the recovery and reuse of critical materials like lithium, cobalt, and nickel, offering a more sustainable and efficient solution than traditional e-waste recycling by minimizing resource extraction and reducing environmental impact.

Urban mining

Urban mining recovers valuable metals from battery recycling more efficiently than general e-waste recycling, significantly reducing the environmental impact of extracting raw materials.

Cathode material recovery

Battery recycling prioritizes cathode material recovery to extract valuable metals like lithium, cobalt, and nickel, whereas e-waste recycling primarily targets broader material reclamation without specialized focus on cathode components.

Pyrometallurgical processing

Pyrometallurgical processing in battery recycling efficiently recovers valuable metals like lithium, cobalt, and nickel by high-temperature smelting, whereas e-waste recycling uses similar techniques but targets a broader range of metals including gold, silver, and copper from diverse electronic components.

Hydrometallurgical leaching

Hydrometallurgical leaching in battery recycling offers higher metal recovery rates and reduced environmental impact compared to conventional e-waste recycling methods.

Black mass separation

Black mass separation in battery recycling efficiently recovers valuable metals like lithium, cobalt, and nickel, offering a higher purity yield compared to general e-waste recycling processes that handle mixed material streams.

Extended producer responsibility (EPR)

Extended Producer Responsibility (EPR) mandates manufacturers to manage the collection, recycling, and safe disposal of batteries and e-waste, incentivizing sustainable product design and reducing environmental impact.

Precious metal reclamation

Battery recycling recovers significantly higher concentrations of precious metals such as lithium, cobalt, and nickel compared to general e-waste recycling, making it a more efficient source for precious metal reclamation.

Secondary raw materials

Battery recycling recovers high-value secondary raw materials such as lithium, cobalt, and nickel more efficiently than general e-waste recycling, which typically yields a broader but less specialized range of recoverable materials.

Hazardous waste management

Battery recycling effectively isolates and manages heavy metals and toxic electrolytes, reducing hazardous waste risks, whereas e-waste recycling broadly targets diverse toxic components like lead, mercury, and flame retardants, necessitating specialized hazardous waste protocols to prevent environmental contamination.

battery recycling vs e-waste recycling Infographic

njnir.com

njnir.com