Dry cooling in nuclear engineering utilizes air to dissipate heat, significantly reducing water consumption compared to wet cooling systems that rely on evaporative cooling with large volumes of water. This method minimizes environmental impact and is especially advantageous in arid regions where water scarcity is a concern. However, dry cooling can be less efficient and more costly due to higher energy requirements for air circulation.

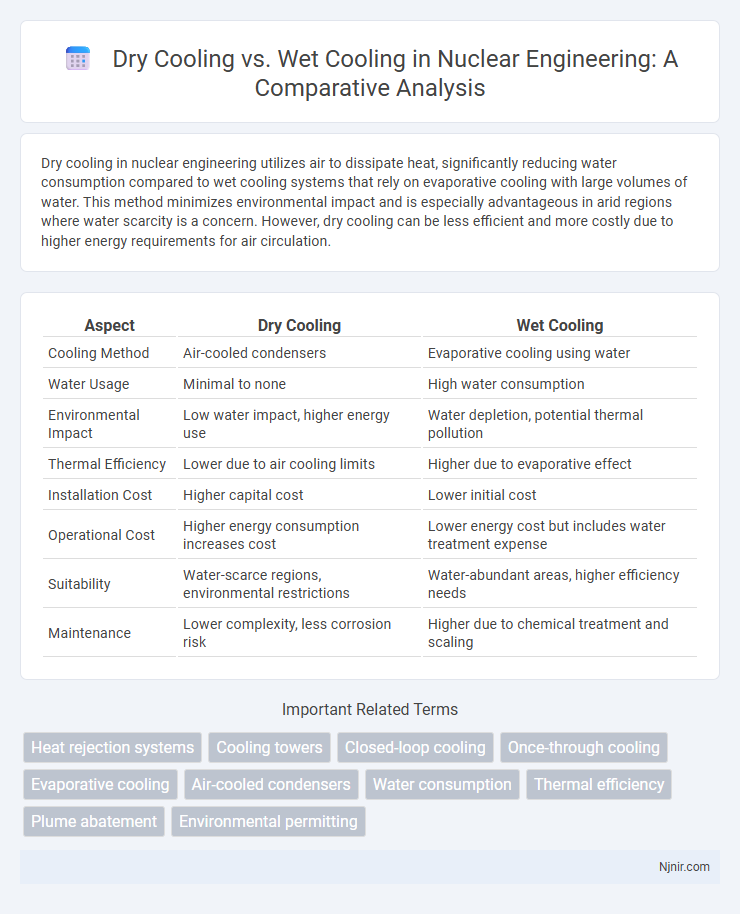

Table of Comparison

| Aspect | Dry Cooling | Wet Cooling |

|---|---|---|

| Cooling Method | Air-cooled condensers | Evaporative cooling using water |

| Water Usage | Minimal to none | High water consumption |

| Environmental Impact | Low water impact, higher energy use | Water depletion, potential thermal pollution |

| Thermal Efficiency | Lower due to air cooling limits | Higher due to evaporative effect |

| Installation Cost | Higher capital cost | Lower initial cost |

| Operational Cost | Higher energy consumption increases cost | Lower energy cost but includes water treatment expense |

| Suitability | Water-scarce regions, environmental restrictions | Water-abundant areas, higher efficiency needs |

| Maintenance | Lower complexity, less corrosion risk | Higher due to chemical treatment and scaling |

Introduction to Cooling Systems in Nuclear Engineering

Dry cooling systems in nuclear engineering use air to dissipate heat without water, reducing water consumption and environmental impact, while wet cooling systems rely on evaporative cooling through water bodies or cooling towers, offering higher thermal efficiency but increased water usage. Dry cooling is preferred in arid regions or where water availability is limited, despite being less efficient due to higher cooling air temperature sensitivity. Wet cooling systems provide better performance in heat rejection but face challenges related to water consumption, thermal pollution, and regulatory constraints.

Fundamentals of Dry Cooling Technology

Dry cooling technology relies on air-cooled heat exchangers to dissipate heat without using water, making it ideal for water-scarce environments and reducing environmental impact. Unlike wet cooling systems that rely on evaporative cooling, dry cooling maintains thermal efficiency through large surface area finned tubes and high-velocity fans to enhance heat transfer. This technology ensures consistent operation even under varying environmental conditions, emphasizing energy efficiency and sustainability in thermal power plants and industrial processes.

Fundamentals of Wet Cooling Technology

Wet cooling technology relies on the evaporation of water to dissipate heat, making it highly efficient for power plant and HVAC system applications. The process involves heat exchangers where warm air passes over water-saturated surfaces, causing water to evaporate and absorb thermal energy. This method achieves lower condenser temperatures compared to dry cooling, enhancing thermodynamic efficiency but requires significant water consumption and management.

Thermal Efficiency: Dry vs. Wet Cooling

Thermal efficiency in wet cooling systems tends to be higher than in dry cooling due to the superior heat transfer capabilities of evaporative processes, which can reduce condenser temperatures and improve turbine performance. Dry cooling systems rely on air-cooled condensers that operate at higher temperatures, resulting in reduced thermal efficiency and increased parasitic power consumption. Optimizing thermal efficiency in power plants requires balancing cooling method selection with water availability and environmental constraints.

Water Consumption and Environmental Impact

Dry cooling systems significantly reduce water consumption by using air to dissipate heat instead of evaporating water, making them ideal for arid regions facing water scarcity. Wet cooling systems rely on large volumes of water for evaporative cooling, which can deplete local water resources and impact aquatic ecosystems. Environmentally, dry cooling minimizes thermal pollution and water withdrawal impacts, while wet cooling can lead to increased water consumption and adverse effects on biodiversity due to discharge of heated water.

Capital and Operating Cost Analysis

Dry cooling systems typically incur higher capital costs due to advanced heat exchanger technology and larger surface area requirements, while wet cooling systems benefit from lower initial investments but face increased water usage costs. Operating expenses for dry cooling are generally lower as they do not rely on continuous water supply or chemical treatment, reducing variable costs and environmental impact. Wet cooling incurs ongoing costs related to water procurement, treatment, and evaporative losses, making dry cooling more economically favorable in water-scarce regions despite higher upfront expenditures.

Site Selection and Geographic Considerations

Dry cooling systems are preferred in arid or water-scarce regions as they minimize water consumption by using air to dissipate heat, making them ideal for locations with limited water resources. Wet cooling requires abundant water availability and is more suitable for sites near large bodies of water or areas with high humidity, where evaporative cooling can be efficiently utilized. Geographic factors like climate, water availability, and environmental regulations strongly influence the choice between dry and wet cooling systems for power plants and industrial facilities.

Regulatory and Safety Implications

Dry cooling systems significantly reduce water consumption compared to wet cooling, aligning with stringent environmental regulations aimed at conserving water resources in drought-prone regions. Regulatory frameworks often impose limits on thermal pollution and chemical discharge, which dry cooling inherently minimizes due to the absence of evaporative water loss and chemical additives. Safety implications favor dry cooling by eliminating risks associated with legionella bacteria proliferation and reducing exposure to hazardous cooling tower chemicals, thereby enhancing compliance with occupational health standards.

Case Studies: Dry and Wet Cooling in Nuclear Plants

Case studies of nuclear plants reveal distinct advantages and limitations of dry and wet cooling systems. Dry cooling maintains lower water consumption by using air to dissipate heat, essential for arid regions like the Palo Verde Nuclear Generating Station in Arizona, while wet cooling offers higher thermal efficiency with cooling towers, as seen in the Vogtle Electric Generating Plant in Georgia. Efficiency trade-offs in thermal performance and environmental impact influence the choice of cooling technology based on site-specific climate and regulatory requirements.

Future Trends in Nuclear Cooling Technologies

Future trends in nuclear cooling technologies emphasize dry cooling systems to reduce water consumption and environmental impact, particularly in arid regions and during drought conditions. Innovations in hybrid cooling models combine the efficiency of wet cooling with the sustainability of dry cooling, optimizing thermal performance and resource use. Advanced materials and heat exchanger designs are being developed to enhance the reliability and cost-effectiveness of dry cooling solutions in next-generation nuclear reactors.

Heat rejection systems

Dry cooling heat rejection systems use air to dissipate heat, offering water conservation benefits, while wet cooling systems rely on evaporative water loss for higher thermal efficiency.

Cooling towers

Dry cooling towers use air to dissipate heat without water evaporation, resulting in lower water consumption and suitability for arid regions, while wet cooling towers rely on evaporative cooling to achieve higher thermal efficiency but consume significant water resources.

Closed-loop cooling

Closed-loop dry cooling systems minimize water consumption by using air-cooled heat exchangers for heat rejection, contrasting with wet cooling systems that rely on evaporative water loss for thermal efficiency.

Once-through cooling

Once-through wet cooling systems use large volumes of water to absorb heat and discharge it back to the source, while once-through dry cooling systems rely on air to dissipate heat, significantly reducing water consumption but requiring larger heat exchange surfaces.

Evaporative cooling

Evaporative cooling in wet cooling systems significantly reduces energy consumption by using water evaporation to dissipate heat, unlike dry cooling systems that rely solely on air, leading to higher efficiency and lower operational costs in suitable climates.

Air-cooled condensers

Air-cooled condensers in dry cooling systems reduce water usage by utilizing ambient air for heat rejection, making them ideal for water-scarce environments despite slightly lower thermal efficiency compared to wet cooling systems.

Water consumption

Dry cooling reduces water consumption by up to 90% compared to wet cooling systems, making it a more sustainable option for power plants in water-scarce regions.

Thermal efficiency

Dry cooling systems typically exhibit lower thermal efficiency than wet cooling systems due to higher heat rejection temperatures and reduced heat transfer rates.

Plume abatement

Dry cooling significantly reduces plume formation compared to wet cooling by minimizing water vapor emissions and preventing visible steam discharge.

Environmental permitting

Dry cooling systems reduce water consumption and face fewer environmental permitting challenges compared to wet cooling systems, which require permits addressing water withdrawal, discharge, and thermal pollution.

dry cooling vs wet cooling Infographic

njnir.com

njnir.com