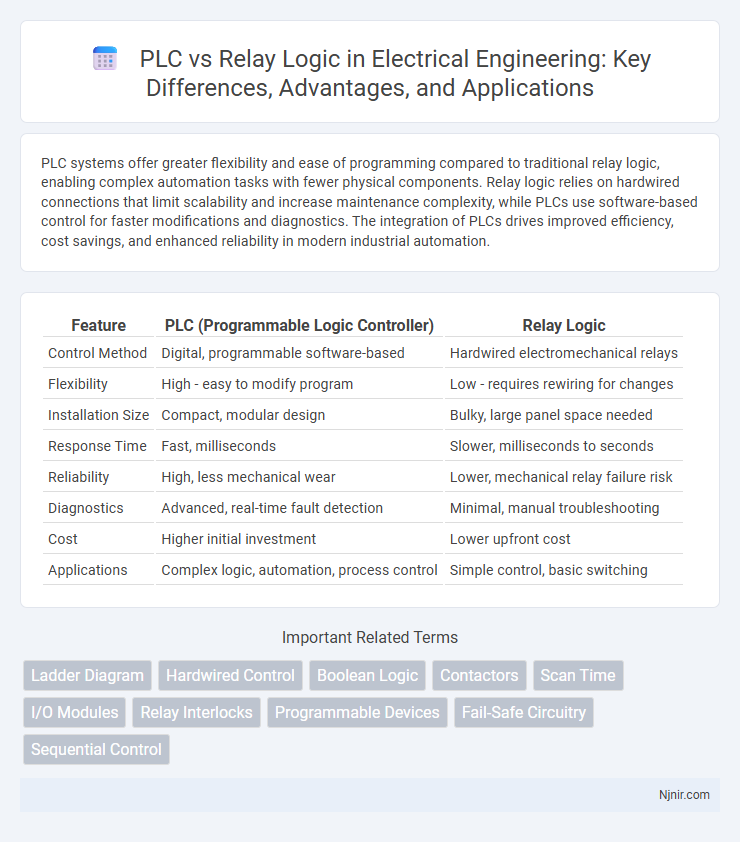

PLC systems offer greater flexibility and ease of programming compared to traditional relay logic, enabling complex automation tasks with fewer physical components. Relay logic relies on hardwired connections that limit scalability and increase maintenance complexity, while PLCs use software-based control for faster modifications and diagnostics. The integration of PLCs drives improved efficiency, cost savings, and enhanced reliability in modern industrial automation.

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | Relay Logic |

|---|---|---|

| Control Method | Digital, programmable software-based | Hardwired electromechanical relays |

| Flexibility | High - easy to modify program | Low - requires rewiring for changes |

| Installation Size | Compact, modular design | Bulky, large panel space needed |

| Response Time | Fast, milliseconds | Slower, milliseconds to seconds |

| Reliability | High, less mechanical wear | Lower, mechanical relay failure risk |

| Diagnostics | Advanced, real-time fault detection | Minimal, manual troubleshooting |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Complex logic, automation, process control | Simple control, basic switching |

Introduction to PLC and Relay Logic

Programmable Logic Controllers (PLCs) are digital computers designed for automation of industrial processes, offering flexibility and easy programming through ladder logic or other languages, making them superior to traditional relay logic. Relay logic uses electromechanical switches for control and is limited by hardware constraints, complexity, and slower response times. PLCs improve reliability, scalability, and diagnostics, which are critical advantages over relay-based control systems in modern manufacturing environments.

Historical Evolution of Control Systems

Relay logic, rooted in electromechanical relays developed in the early 20th century, laid the foundation for automated control systems in manufacturing and industrial processes. The introduction of Programmable Logic Controllers (PLCs) in the late 1960s revolutionized control by replacing complex relay-based wiring with software-based logic, enhancing flexibility, scalability, and maintenance efficiency. PLCs rapidly became the standard due to their ability to handle complex control sequences, real-time processing, and integration with digital communication protocols.

Fundamental Principles of Relay Logic

Relay logic operates on electromagnetic switches using coils and contacts to open or close circuits based on electrical input conditions, enabling simple control sequences. Its fundamental principle lies in the physical actuation of relays to perform logical operations such as AND, OR, and NOT through series and parallel wiring. Unlike PLCs, relay logic relies entirely on hardware components without software programming, making it suitable for basic, discrete control tasks but less flexible for complex automation.

PLC Architecture and Operation Basics

PLC architecture consists of a central processing unit (CPU), memory, input/output (I/O) modules, and a power supply, enabling efficient control and automation processes. The CPU executes ladder logic or other programming languages, continuously scanning inputs, processing logic, and updating outputs to control machinery in real time. Relay logic relies on physical electromechanical relays that switch circuits by energizing coils, contrasting PLCs' flexible, software-driven architecture that supports complex, adaptive control tasks.

Key Differences Between PLCs and Relay Logic

PLCs (Programmable Logic Controllers) offer flexible programming capabilities, allowing for easy modifications and complex control processes, whereas relay logic relies on hardwired physical contacts, making changes cumbersome. PLCs provide faster operation speeds, diagnostics, and integration with modern automation systems, contrasting with the slower, less efficient performance of relay logic. Maintenance and scalability favor PLCs due to software-driven configurations, eliminating the extensive wiring and component wear associated with relay logic setups.

Advantages of PLCs Over Relay Logic

PLCs offer superior flexibility and scalability compared to relay logic, allowing easy program modifications without hardware changes. They provide faster processing speeds and advanced diagnostics, reducing downtime and improving system reliability. PLCs also support complex control algorithms and integration with modern industrial networks, enhancing overall automation efficiency.

Limitations and Challenges of PLCs and Relays

PLCs face limitations such as high initial costs, complexity in programming, and vulnerability to electromagnetic interference, which can disrupt signal processing. Relay logic systems encounter challenges including slower operation speeds, mechanical wear, and limited scalability for complex processes. Both technologies present constraints in flexibility and maintenance, affecting their suitability for evolving industrial automation demands.

Application Areas: When to Use PLC or Relay Logic

PLC systems excel in complex automation environments requiring flexibility, scalability, and precise control, such as manufacturing lines, process industries, and building automation. Relay logic suits simpler, discrete control tasks with limited inputs and outputs, commonly found in basic machinery, safety circuits, and legacy equipment. Choosing PLC over relay logic enhances diagnostics, programming ease, and adaptability in dynamic or expanding applications.

Cost Analysis and Scalability Considerations

Programmable Logic Controllers (PLCs) typically offer lower long-term costs due to reduced wiring complexity and easier programming compared to relay logic, which incurs higher initial expenses from extensive hardware and maintenance. Scalability favors PLCs, as adding new functions or expanding systems requires minimal physical changes, whereas relay logic demands significant rewiring and additional components for expansion. The modular design of PLCs supports flexible growth in automation systems, making them more cost-effective and adaptable for evolving industrial applications.

Future Trends in Industrial Control Systems

Future trends in industrial control systems emphasize the widespread adoption of PLCs (Programmable Logic Controllers) due to their enhanced flexibility, scalability, and integration with IoT (Internet of Things) technologies. Advanced PLCs incorporate AI-driven diagnostics and predictive maintenance capabilities, surpassing traditional relay logic's fixed, hardware-based control limitations. The shift towards smart factories and Industry 4.0 accelerates the replacement of relay logic with PLCs that support real-time data analytics and seamless connectivity across complex automation networks.

Ladder Diagram

Ladder Diagrams in PLCs provide programmable, flexible, and easily modifiable control logic compared to fixed-function relay logic, enabling efficient automation and troubleshooting.

Hardwired Control

Hardwired control in relay logic uses fixed wiring and physical relays for automation, offering simplicity and reliability but lacking the flexibility and programmability of PLC systems.

Boolean Logic

PLC systems use programmable Boolean logic for versatile and complex control operations, whereas relay logic relies on fixed physical connections to perform basic Boolean functions.

Contactors

Contactors in PLC systems offer faster, more reliable switching with programmable control compared to the mechanical wear and limited scalability of relay logic contactors.

Scan Time

PLC scan time, typically measured in milliseconds, allows faster and more precise control cycles compared to the slower, mechanical switching speeds of relay logic systems.

I/O Modules

PLC I/O modules provide scalable, programmable input and output control with enhanced diagnostics compared to fixed-function relay logic I/O modules.

Relay Interlocks

Relay interlocks provide hardware-based safety by physically preventing conflicting machine operations, whereas PLCs offer programmable, flexible control with software-based interlocks enhancing system adaptability and diagnostics.

Programmable Devices

Programmable Logic Controllers (PLCs) offer advanced programmable devices that enable flexible, scalable, and precise control compared to traditional relay logic systems, enhancing automation efficiency across industrial applications.

Fail-Safe Circuitry

PLC systems enhance fail-safe circuitry by enabling real-time diagnostics and automatic fault isolation, whereas relay logic relies on physical wiring configurations that limit rapid fault detection and response.

Sequential Control

PLC systems enable more efficient and flexible sequential control compared to relay logic by using programmable software to manage complex sequences and reduce wiring complexity.

PLC vs relay logic Infographic

njnir.com

njnir.com