Hydrogels provide a highly hydrated, biocompatible environment that mimics natural extracellular matrix, promoting cell proliferation and nutrient diffusion in tissue engineering. Electrospun scaffolds offer a fibrous architecture with high surface-area-to-volume ratio, enhancing cell attachment and mechanical strength for vascular and skin tissue regeneration. The choice between hydrogels and electrospun scaffolds depends on the specific application's requirements for structural integrity and biological functionality.

Table of Comparison

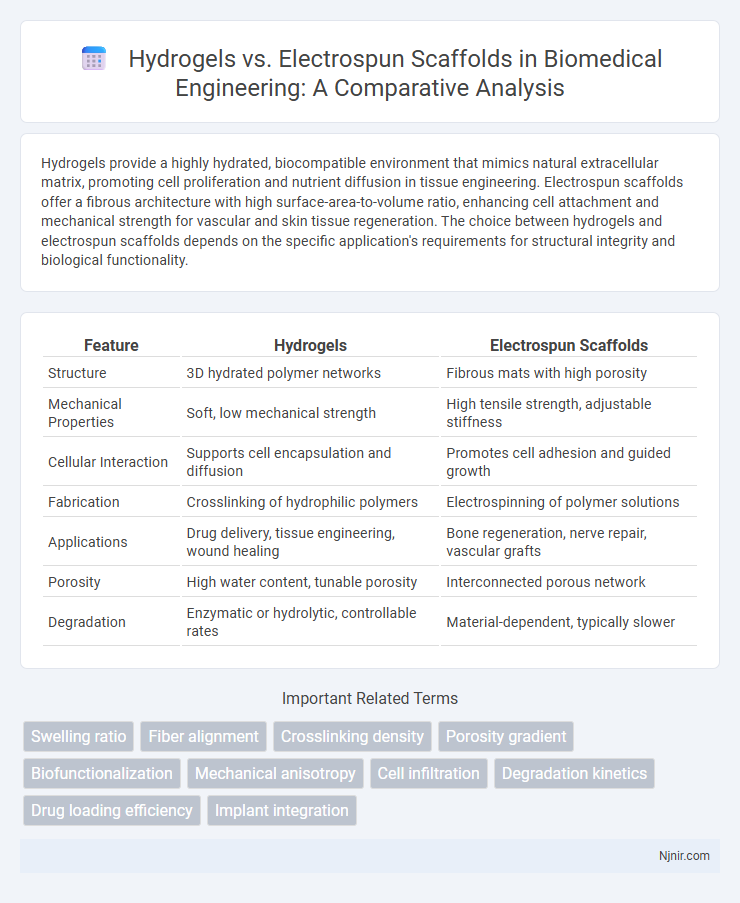

| Feature | Hydrogels | Electrospun Scaffolds |

|---|---|---|

| Structure | 3D hydrated polymer networks | Fibrous mats with high porosity |

| Mechanical Properties | Soft, low mechanical strength | High tensile strength, adjustable stiffness |

| Cellular Interaction | Supports cell encapsulation and diffusion | Promotes cell adhesion and guided growth |

| Fabrication | Crosslinking of hydrophilic polymers | Electrospinning of polymer solutions |

| Applications | Drug delivery, tissue engineering, wound healing | Bone regeneration, nerve repair, vascular grafts |

| Porosity | High water content, tunable porosity | Interconnected porous network |

| Degradation | Enzymatic or hydrolytic, controllable rates | Material-dependent, typically slower |

Introduction to Biomaterial Scaffolds in Biomedical Engineering

Hydrogels and electrospun scaffolds represent key biomaterial platforms in biomedical engineering, offering distinct advantages for tissue engineering applications. Hydrogels provide a hydrated, three-dimensional matrix facilitating cell encapsulation and nutrient diffusion, closely mimicking natural extracellular matrix properties. Electrospun scaffolds deliver highly porous, fibrous structures with tunable fiber diameters and mechanical strength, enhancing cell attachment and proliferation critical for tissue regeneration.

Fundamental Properties of Hydrogels

Hydrogels possess high water content, mimicking natural extracellular matrices, which facilitates cell proliferation and nutrient diffusion. Their viscoelastic properties and tunable mechanical strength allow customization for specific tissue engineering applications. Furthermore, hydrogels exhibit excellent biocompatibility and biodegradability, making them ideal for controlled drug delivery and wound healing scaffolds.

Core Characteristics of Electrospun Scaffolds

Electrospun scaffolds feature highly porous structures with interconnected fibers, offering a large surface area that promotes enhanced cell attachment and proliferation. Their nanofibrous architecture closely mimics the natural extracellular matrix, providing mechanical support and facilitating nutrient diffusion. Compared to hydrogels, electrospun scaffolds exhibit superior mechanical strength and tunable fiber alignment, essential for tissue engineering applications requiring directional cell growth.

Fabrication Techniques: Hydrogels vs Electrospinning

Hydrogels are fabricated using techniques such as polymerization, crosslinking, or physical gelation, allowing precise control over their swelling properties and mechanical strength. Electrospun scaffolds are produced by electrically drawing polymer solutions into fine fibers, creating nanofibrous mats with high surface area and porosity ideal for tissue engineering. While hydrogel fabrication emphasizes chemical crosslinking and tunable viscoelasticity, electrospinning focuses on fiber morphology and alignment through parameters like voltage, flow rate, and collector design.

Mechanical Strength and Structural Integrity

Hydrogels exhibit high water content and biocompatibility but often suffer from limited mechanical strength, restricting their use in load-bearing tissue engineering applications. Electrospun scaffolds provide superior mechanical strength and structural integrity due to their fibrous architecture, closely mimicking natural extracellular matrices. Optimizing fiber alignment and scaffold porosity in electrospun materials enhances mechanical properties, making them ideal for applications requiring durability and support.

Biocompatibility and Cellular Response

Hydrogels offer superior biocompatibility due to their high water content and similarity to natural extracellular matrix, promoting enhanced cell viability and proliferation. Electrospun scaffolds provide a fibrous structure that mimics native tissue architecture, supporting cellular adhesion, differentiation, and directional growth. Both materials exhibit distinct cellular responses, with hydrogels favoring soft tissue regeneration and electrospun scaffolds excelling in applications requiring mechanical strength and cellular alignment.

Controlled Drug Delivery Capabilities

Hydrogels provide a highly porous, hydrated network enabling sustained release of drugs through diffusion, ideal for controlled drug delivery in tissue engineering and wound healing. Electrospun scaffolds offer nanofibrous structures with tunable fiber diameter and surface area, enhancing drug loading capacity and enabling targeted, controlled release profiles. Combining hydrogels with electrospun scaffolds can synergistically improve drug delivery by merging the hydrophilic environment of hydrogels with the structural support and controlled degradation of nanofibers.

Tissue Regeneration Applications

Hydrogels provide a highly hydrated, biocompatible matrix that mimics the extracellular environment, promoting cell proliferation and differentiation critical for tissue regeneration. Electrospun scaffolds offer a fibrous structure with high surface area and porosity, facilitating cell adhesion and nutrient diffusion essential for effective tissue growth. Combining hydrogels with electrospun scaffolds can synergistically enhance mechanical properties and biological functionality, optimizing outcomes in regenerative medicine.

Challenges and Limitations of Each Scaffold Type

Hydrogels face challenges such as limited mechanical strength and slow degradation rates, restricting their use in load-bearing tissue engineering applications. Electrospun scaffolds exhibit limitations in cell infiltration and nutrient diffusion due to their dense fiber networks and small pore sizes. Both scaffold types require optimization to balance biocompatibility, structural integrity, and functional performance for specific regenerative medicine applications.

Future Prospects in Scaffold-Based Biomedical Engineering

Hydrogels offer excellent biocompatibility and tunable mechanical properties ideal for mimicking native tissue environments, while electrospun scaffolds provide superior structural integrity and high surface-area-to-volume ratios essential for cell attachment and proliferation. Future prospects in scaffold-based biomedical engineering involve integrating hydrogel matrices with electrospun nanofibers to create hybrid scaffolds that combine the advantages of both materials for enhanced tissue regeneration. Advances in biomaterial synthesis and 3D bioprinting technologies are expected to optimize these composite scaffolds, improving their functionality in personalized medicine and complex tissue engineering applications.

Swelling ratio

Hydrogels typically exhibit a higher swelling ratio compared to electrospun scaffolds due to their hydrophilic polymer networks, enabling greater water absorption and retention essential for tissue engineering applications.

Fiber alignment

Fiber alignment in electrospun scaffolds enhances cellular orientation and mechanical properties, whereas hydrogels typically exhibit isotropic structures with limited control over fiber orientation.

Crosslinking density

Crosslinking density in hydrogels significantly influences mechanical strength and swelling properties, whereas in electrospun scaffolds, it primarily affects fiber stability and cellular interaction.

Porosity gradient

Hydrogels exhibit a highly tunable porosity gradient that mimics natural tissue extracellular matrices, whereas electrospun scaffolds offer controlled fiber alignment but typically have less precise porosity gradients affecting cell infiltration and nutrient diffusion.

Biofunctionalization

Biofunctionalization of hydrogels enhances cell adhesion and controlled biomolecule delivery, while electrospun scaffolds offer superior structural support and surface modification for targeted tissue regeneration.

Mechanical anisotropy

Electrospun scaffolds exhibit pronounced mechanical anisotropy due to fiber alignment, whereas hydrogels typically present isotropic mechanical properties because of their homogeneous polymer networks.

Cell infiltration

Electrospun scaffolds exhibit superior cell infiltration compared to hydrogels due to their porous fiber architecture that facilitates deeper cellular penetration and tissue integration.

Degradation kinetics

Hydrogels exhibit slower and more uniform degradation kinetics compared to electrospun scaffolds, which typically degrade faster due to their higher surface area and porous fiber structure.

Drug loading efficiency

Electrospun scaffolds demonstrate higher drug loading efficiency than hydrogels due to their increased surface area and porous structure, enabling improved drug encapsulation and controlled release.

Implant integration

Hydrogels provide enhanced biocompatibility and moisture retention for implant integration, while electrospun scaffolds offer superior structural support and mimic native extracellular matrix, promoting improved cell adhesion and tissue regeneration.

Hydrogels vs Electrospun scaffolds Infographic

njnir.com

njnir.com