Adsorption involves the adhesion of molecules onto the surface of a solid or liquid, creating a concentrated layer, whereas absorption entails the uniform penetration of a substance throughout the bulk phase of a liquid or solid. In chemical engineering, adsorption is commonly utilized for separation and purification processes due to its selectivity and reversibility, while absorption is frequently applied for gas-liquid interactions such as solvent scrubbing. Understanding the distinct mechanisms and applications of adsorption versus absorption is critical for optimizing mass transfer operations and designing efficient reactors.

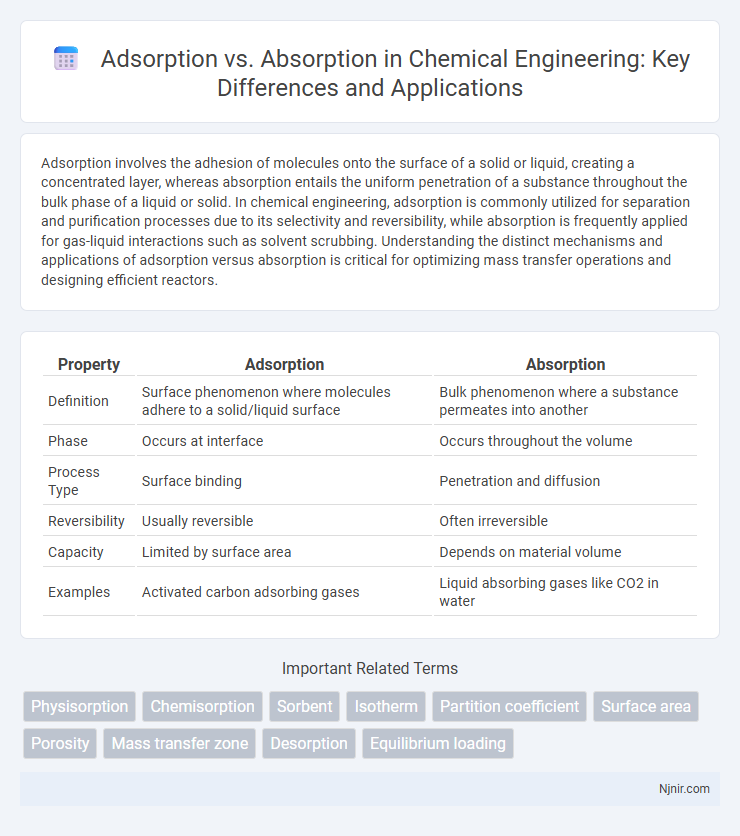

Table of Comparison

| Property | Adsorption | Absorption |

|---|---|---|

| Definition | Surface phenomenon where molecules adhere to a solid/liquid surface | Bulk phenomenon where a substance permeates into another |

| Phase | Occurs at interface | Occurs throughout the volume |

| Process Type | Surface binding | Penetration and diffusion |

| Reversibility | Usually reversible | Often irreversible |

| Capacity | Limited by surface area | Depends on material volume |

| Examples | Activated carbon adsorbing gases | Liquid absorbing gases like CO2 in water |

Definition of Adsorption and Absorption

Adsorption is the process where molecules from a gas, liquid, or dissolved solid adhere to the surface of a solid or liquid, forming a thin film on the adsorbent's surface. Absorption involves the full integration of molecules into the bulk phase of a solid or liquid, where the absorbed substance permeates or dissolves throughout the absorbing material. The key distinction lies in adsorption being a surface phenomenon, whereas absorption occurs throughout the volume of the absorbing substance.

Fundamental Differences Between Adsorption and Absorption

Adsorption is a surface phenomenon where molecules adhere only to the surface of a solid or liquid, while absorption involves the entire volume of the absorbing material, with molecules penetrating uniformly. Adsorption is typically reversible and depends on surface area and interaction forces, whereas absorption is often irreversible and depends on the material's capacity to dissolve or assimilate the substance. The fundamental distinction lies in adsorption's surface-based accumulation versus absorption's bulk integration within the material.

Mechanisms of Adsorption

Adsorption involves the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid onto a surface, creating a film of the adsorbate on the adsorbent. This process is driven by physical forces such as van der Waals interactions or chemical bonds forming between the adsorbate and the surface, categorized as physisorption or chemisorption respectively. Surface area, porosity, and the nature of the adsorbent significantly influence the adsorption capacity and efficiency, distinguishing it fundamentally from absorption, which entails the bulk uptake of substances.

Mechanisms of Absorption

Absorption involves the penetration of a substance into the bulk phase of a solid or liquid, where molecular diffusion governs the transport process. This mechanism relies on the interaction between the absorbate and absorbent, often described by Henry's law in gas-liquid systems or partition coefficients in liquid-liquid systems. Unlike adsorption, absorption results in the uniform distribution of the absorbed material throughout the absorbent's volume rather than surface accumulation.

Key Factors Influencing Adsorption

Key factors influencing adsorption include surface area, temperature, and adsorbent nature, with higher surface areas typically enhancing adsorption capacity. The adsorption process is exothermic, so lower temperatures generally favor increased adsorption. Adsorbent porosity and chemical composition affect the affinity and selectivity toward specific adsorbates, playing a critical role in adsorption efficiency.

Key Factors Influencing Absorption

Absorption efficiency depends on factors such as temperature, pressure, concentration gradients, and the physical and chemical properties of the absorbent and absorbate. Higher temperatures generally decrease gas absorption due to reduced solubility, while increased pressure enhances gas solubility and absorption rates. The nature of the absorbent, including its phase (liquid or solid), surface area, and chemical affinity for the absorbate, significantly impacts absorption performance.

Industrial Applications of Adsorption

Adsorption plays a critical role in various industrial applications such as gas purification, wastewater treatment, and catalysis due to its ability to selectively capture contaminants on solid surfaces. Activated carbon, zeolites, and silica gels serve as common adsorbents, efficiently removing volatile organic compounds, heavy metals, and harmful gases in petrochemical plants and environmental engineering. Unlike absorption, which involves the entire volume of the absorbent, adsorption's surface-specific process allows for high regeneration capacity and cost-effective pollutant removal in large-scale industrial operations.

Industrial Applications of Absorption

Absorption in industrial applications primarily involves the transfer of gases or vapors into liquids, widely used in processes like scrubbing pollutants from exhaust gases, such as removing sulfur dioxide in flue gas desulfurization. This method is critical in chemical manufacturing for separating and purifying compounds, including the absorption of ammonia or carbon dioxide in various gas processing plants. Unlike adsorption, which occurs at the surface, absorption allows deeper penetration of substances, making it essential for large-scale environmental control and chemical reactions.

Advantages and Limitations: Adsorption vs Absorption

Adsorption offers advantages such as selective separation, high efficiency at low concentrations, and easier regeneration of adsorbents, but it is limited by capacity constraints and sensitivity to temperature and pressure variations. Absorption provides deeper penetration of substances, suitability for large-scale continuous processes, and better handling of gaseous or liquid mixtures, yet it faces challenges including slower rates, potential for solvent contamination, and higher energy requirements for regeneration. Both processes are essential in industrial applications, with adsorption favoring surface-based interactions and absorption relying on volume-based uptake mechanisms.

Selection Criteria in Chemical Engineering Processes

Selection criteria for adsorption versus absorption in chemical engineering emphasize factors such as process efficiency, material compatibility, and operational conditions. Adsorption is preferred when reversible surface interactions and selective separation of specific molecules are required, benefiting applications with low material degradation and easy regeneration. Absorption is chosen for bulk mass transfer involving liquid or gas phases, favoring processes with large capacity, fast equilibrium, and where solute incorporation affects the absorbent's bulk phase properties.

Physisorption

Physisorption involves the weak van der Waals forces attaching gas molecules to a solid surface, distinguishing it from absorption which entails the penetration of substances into the bulk phase.

Chemisorption

Chemisorption involves the chemical bonding of molecules to a surface during adsorption, creating a stronger, often irreversible interaction compared to the physical process of absorption.

Sorbent

Sorbents in adsorption capture molecules on their surface without penetrating the bulk, whereas in absorption, sorbents take in substances throughout their entire volume.

Isotherm

Adsorption isotherms describe the relationship between the amount of adsorbate on the adsorbent surface and its concentration at constant temperature, while absorption involves the bulk phase uptake without such surface concentration equilibrium modeling.

Partition coefficient

The partition coefficient quantifies the distribution ratio in absorption by indicating how a substance divides between two phases, whereas adsorption involves accumulation at surfaces without a partition coefficient measurement.

Surface area

Adsorption efficiency significantly increases with larger surface area due to substance adherence on surfaces, while absorption involves bulk material uptake with less dependence on surface area.

Porosity

Adsorption occurs on the surface of porous materials where large surface area and pore volume enhance molecule adherence, whereas absorption involves penetration of substances into the bulk phase of porous structures, influenced by pore size and connectivity.

Mass transfer zone

The mass transfer zone in adsorption is typically thinner and more defined due to surface interaction, whereas in absorption it extends deeper into the bulk phase owing to diffusion-driven penetration.

Desorption

Desorption is the process where adsorbed molecules detach from a surface, contrasting absorption, which involves molecules penetrating a bulk phase.

Equilibrium loading

Equilibrium loading in adsorption refers to the maximum amount of adsorbate retained on the surface at equilibrium, whereas in absorption it denotes the quantity uniformly distributed within the bulk phase.

Adsorption vs Absorption Infographic

njnir.com

njnir.com