Downstream processing involves the purification, separation, and recovery of desired products from fermentation or reaction mixtures, ensuring product quality and safety. Upstream processing focuses on the preparation and cultivation of microorganisms or cells, optimizing growth conditions to maximize product yield. Both stages are essential in chemical engineering for efficient bioprocessing and product development.

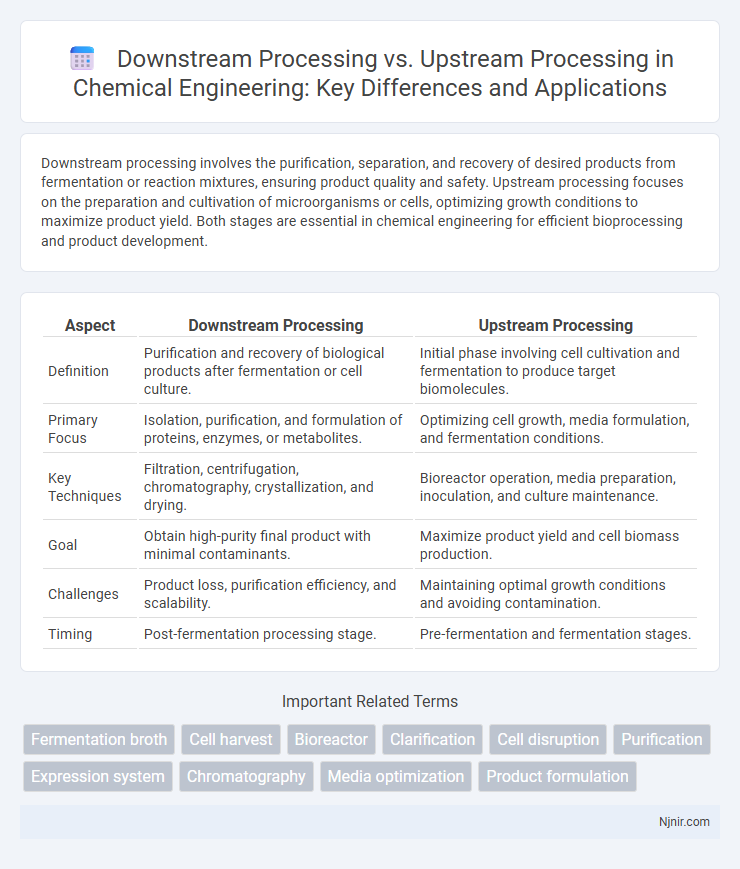

Table of Comparison

| Aspect | Downstream Processing | Upstream Processing |

|---|---|---|

| Definition | Purification and recovery of biological products after fermentation or cell culture. | Initial phase involving cell cultivation and fermentation to produce target biomolecules. |

| Primary Focus | Isolation, purification, and formulation of proteins, enzymes, or metabolites. | Optimizing cell growth, media formulation, and fermentation conditions. |

| Key Techniques | Filtration, centrifugation, chromatography, crystallization, and drying. | Bioreactor operation, media preparation, inoculation, and culture maintenance. |

| Goal | Obtain high-purity final product with minimal contaminants. | Maximize product yield and cell biomass production. |

| Challenges | Product loss, purification efficiency, and scalability. | Maintaining optimal growth conditions and avoiding contamination. |

| Timing | Post-fermentation processing stage. | Pre-fermentation and fermentation stages. |

Introduction to Upstream and Downstream Processing

Upstream processing involves the initial stages of biomanufacturing, including cell culture, fermentation, and biomass production, where biological materials are cultivated to generate target products. Downstream processing focuses on the purification and recovery of these bioproducts, employing techniques such as filtration, centrifugation, chromatography, and formulation to obtain a final, purified product. Both processes are integral to biopharmaceutical manufacturing, ensuring the efficient production and quality of biological therapeutics.

Definitions and Key Differences

Downstream processing involves the purification and recovery of biological products after fermentation or cell cultivation, including filtration, centrifugation, and chromatography. Upstream processing refers to the initial phase of bioproduction, encompassing cell line development, culture media preparation, and optimization of growth conditions for biomass or product formation. Key differences lie in their functional focus: upstream processing is centered on producing the biological material, while downstream processing concentrates on isolating and refining the final product to meet quality standards.

Major Stages in Upstream Processing

Upstream processing primarily involves the cultivation of microorganisms or cells under controlled conditions to produce desired biological products, encompassing key stages such as media preparation, inoculum development, and fermentation or cell culture. These stages ensure optimal growth and product formation by regulating factors like temperature, pH, oxygen supply, and nutrient availability. Effective upstream processing directly influences downstream efficiency, as the quality and quantity of the bioproduct depend on the conditions maintained during these major stages.

Key Steps in Downstream Processing

Downstream processing involves key steps such as cell disruption, centrifugation, filtration, chromatography, and formulation to purify biomolecules after upstream production. Techniques like ultrafiltration and lyophilization are crucial for concentrating and stabilizing the final product. These processes ensure high purity, yield, and bioactivity of pharmaceuticals or bioproducts derived from fermentation or cell culture upstream.

Equipment Used in Upstream vs Downstream Processes

Upstream processing primarily involves equipment like bioreactors, fermenters, and seed tanks designed for cell growth, culture development, and biomass production. Downstream processing utilizes centrifuges, filtration systems, chromatography columns, and dryers to purify, concentrate, and formulate the final biological product. The distinct equipment sets highlight the transition from biological synthesis in upstream to purification and refinement in downstream operations.

Quality Control in Upstream and Downstream Processing

Quality control in upstream processing emphasizes monitoring cell culture conditions, such as nutrient levels, pH, temperature, and contamination, to ensure optimal growth and product consistency. In downstream processing, quality control focuses on purification, including filtration, chromatography, and virus removal, to achieve the desired product purity, potency, and safety. Both stages implement rigorous analytical testing and process validation to meet regulatory standards and guarantee overall biopharmaceutical quality.

Challenges and Limitations

Downstream processing faces challenges such as product loss during purification, high operational costs, and difficulties in scaling up due to complex separation techniques. Upstream processing encounters limitations including contamination risks, variable cell growth rates, and the need for precise control of environmental conditions to optimize yield. Both processes demand advanced technologies and robust monitoring to overcome bottlenecks and ensure consistent bioproduct quality.

Process Optimization Strategies

Downstream processing optimization focuses on improving purification techniques such as chromatography, filtration, and centrifugation to enhance product yield and purity while reducing time and cost. Upstream processing optimization emphasizes cell culture conditions, media formulation, and bioreactor control parameters to maximize biomass and product formation. Integrating real-time monitoring and advanced control algorithms in both upstream and downstream stages drives overall bioprocess efficiency and scalability.

Industrial Applications and Case Studies

Downstream processing involves the purification and recovery of bioproducts from fermentation broth or cell cultures, essential in pharmaceuticals for producing sterile proteins and vaccines, as illustrated by Genentech's monoclonal antibody purification. Upstream processing focuses on biomass production through cell culture or fermentation, exemplified by the large-scale cultivation of E. coli in biofuel manufacturing at companies like Amyris. Industrial applications demonstrate that optimizing upstream parameters can enhance yield and quality, while efficient downstream techniques reduce production costs and improve product purity, as evidenced in case studies from the biotech and chemical industries.

Future Trends in Bioprocessing

Future trends in bioprocessing emphasize advanced integration of upstream processing techniques such as continuous fermentation with real-time monitoring and control using AI-driven algorithms to enhance cell growth and product yield. Downstream processing is evolving to incorporate novel purification technologies like membrane chromatography and single-use systems that reduce processing time and costs while ensuring higher product purity. The convergence of digital twins and automation across both downstream and upstream stages is expected to drive efficiency, scalability, and robustness in biopharmaceutical manufacturing pipelines.

Fermentation broth

Downstream processing involves purification and recovery of target products from the fermentation broth, while upstream processing focuses on optimizing microbial growth and metabolite production within the broth.

Cell harvest

Downstream processing in biomanufacturing focuses on cell harvest techniques such as centrifugation and filtration to isolate target biomolecules, whereas upstream processing involves cultivation and growth optimization of cells prior to harvest.

Bioreactor

Downstream processing involves purifying and isolating bioproducts after bioreactor cultivation, while upstream processing focuses on optimizing cell growth and product formation within the bioreactor.

Clarification

Downstream processing involves clarification techniques such as filtration and centrifugation to remove impurities and cell debris, whereas upstream processing focuses on cell growth and product expression without clarification steps.

Cell disruption

Cell disruption in downstream processing efficiently releases intracellular products following upstream cell cultivation and growth.

Purification

Downstream processing focuses on purification by isolating and refining the desired product from fermentation or cell culture, whereas upstream processing involves the initial cultivation and production of biological materials.

Expression system

Downstream processing involves purification and recovery of a product from an expression system, while upstream processing focuses on the cultivation and optimization of the expression system to maximize product yield.

Chromatography

Chromatography in downstream processing is crucial for purifying biomolecules separated during upstream processing, which focuses on cell growth and product formation.

Media optimization

Media optimization in downstream processing enhances product recovery and purification efficiency, whereas in upstream processing, it focuses on maximizing cell growth and product yield.

Product formulation

Downstream processing refines and purifies bio-products after Upstream processing, which involves the initial cultivation and product synthesis stages critical for effective product formulation.

Downstream processing vs Upstream processing Infographic

njnir.com

njnir.com