Machine learning offers the ability to model complex chemical processes by learning patterns from large datasets without requiring explicit physical equations, enhancing prediction accuracy in non-linear systems. Classical modeling relies on fundamental chemical engineering principles and equations derived from first-principles, providing interpretability and reliability when system behavior is well understood. Combining machine learning with classical modeling can optimize process control and design by leveraging data-driven insights alongside established theoretical frameworks.

Table of Comparison

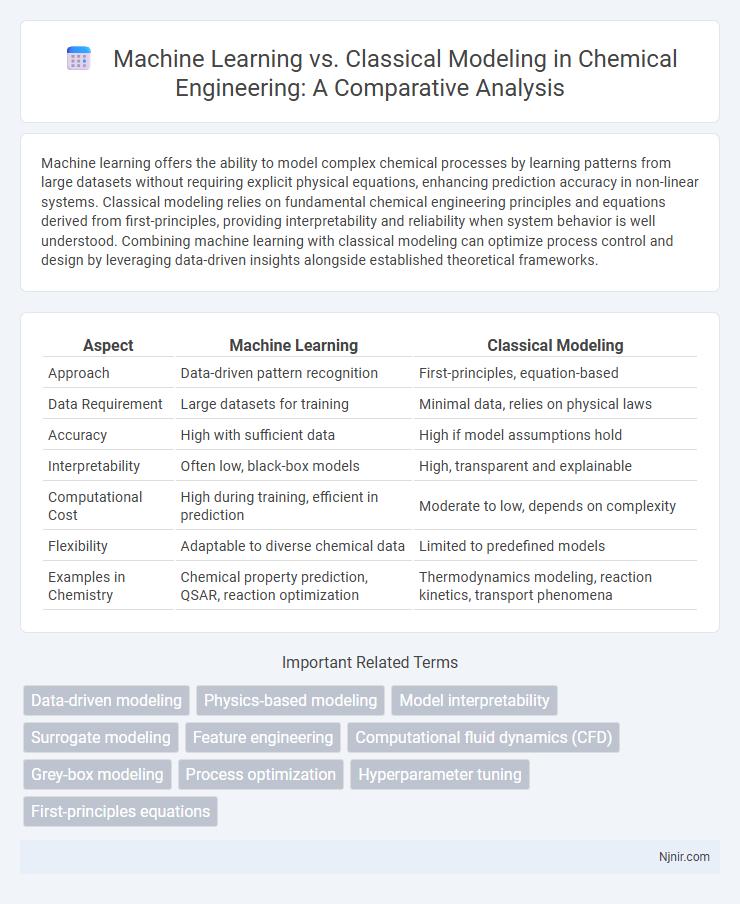

| Aspect | Machine Learning | Classical Modeling |

|---|---|---|

| Approach | Data-driven pattern recognition | First-principles, equation-based |

| Data Requirement | Large datasets for training | Minimal data, relies on physical laws |

| Accuracy | High with sufficient data | High if model assumptions hold |

| Interpretability | Often low, black-box models | High, transparent and explainable |

| Computational Cost | High during training, efficient in prediction | Moderate to low, depends on complexity |

| Flexibility | Adaptable to diverse chemical data | Limited to predefined models |

| Examples in Chemistry | Chemical property prediction, QSAR, reaction optimization | Thermodynamics modeling, reaction kinetics, transport phenomena |

Introduction to Modeling in Chemical Engineering

Machine learning offers data-driven predictive capabilities that complement classical modeling's reliance on fundamental physical and chemical principles in chemical engineering. Classical modeling uses differential equations and thermodynamics to describe process behavior, while machine learning leverages algorithms to identify patterns in experimental and process data. Integrating both approaches enhances accuracy and adaptability in simulating complex chemical systems and process optimization.

Fundamentals of Classical Modeling Techniques

Classical modeling techniques rely on mathematical equations and statistical methods to represent systems based on predefined assumptions and domain knowledge, ensuring interpretability and robustness in predictions. These models, such as linear regression, differential equations, and time series analysis, emphasize explicit relationships between variables and underlying physical processes. Their foundation in theory-driven approaches allows for clear validation and understanding, making them essential in fields requiring transparency and explainability.

Principles of Machine Learning in Chemical Engineering

Machine learning in chemical engineering leverages algorithms to automatically identify patterns and relationships within complex datasets, enabling predictive modeling without explicit programming. Unlike classical modeling, which relies on fundamental physical and chemical principles to derive mathematical equations, machine learning emphasizes data-driven approaches for optimization and process control. Key principles include feature selection, model training, validation, and iterative improvement to accurately capture nonlinear behaviors in chemical processes.

Data Requirements: Classical Models vs Machine Learning

Classical modeling relies on smaller, structured datasets with predefined features, making it suitable for scenarios where domain knowledge guides feature selection and data is limited. Machine learning demands large volumes of diverse, high-quality data to learn patterns automatically, excelling in complex problems where feature engineering is impractical. While classical models prioritize interpretability and simplicity, machine learning leverages data scale and variety to enhance predictive performance.

Predictive Performance and Accuracy Comparison

Machine learning techniques generally outperform classical modeling in predictive performance due to their ability to capture complex, nonlinear relationships within large datasets. Classical models, such as linear regression or ARIMA, often rely on strict assumptions and may struggle with high-dimensional data or subtle feature interactions, limiting their accuracy. Empirical studies demonstrate that machine learning algorithms like random forests, gradient boosting, and neural networks achieve higher accuracy and lower prediction error rates in diverse domains, including finance, healthcare, and marketing.

Model Interpretability and Explainability

Machine learning models, especially deep learning, often excel in prediction accuracy but tend to lack transparent interpretability compared to classical modeling techniques like linear regression or decision trees, which provide clear, human-understandable relationships between variables. Classical models facilitate straightforward explainability by offering coefficients and rule-based structures that domain experts can easily analyze, while machine learning models require specialized tools such as SHAP or LIME to interpret complex feature interactions. Prioritizing model interpretability and explainability is crucial in regulated industries where understanding decision rationale impacts trust, compliance, and actionable insights.

Computational Resources and Scalability

Machine learning algorithms often require significant computational resources, including high-performance GPUs and large memory capacities, to process extensive datasets and complex models, whereas classical modeling relies on simpler mathematical formulations that demand less processing power. Scalability in machine learning is enhanced by distributed computing frameworks like Apache Spark and TensorFlow, enabling efficient handling of growing data volumes and model complexity. Classical modeling scalability is limited by the exponential increase in computation time and difficulty in extending models to large, high-dimensional datasets.

Applications in Process Optimization

Machine learning excels in process optimization by leveraging large datasets to identify complex patterns and continuously improve performance in real-time, outperforming classical modeling approaches that rely on predefined equations and assumptions. Classical models provide strong theoretical insights and are highly effective for well-understood systems, but they often struggle with nonlinearities and dynamic changes inherent in industrial processes. Machine learning applications in industries such as chemical manufacturing and energy production demonstrate superior adaptability and predictive accuracy, enabling more efficient resource utilization and reduced operational costs.

Challenges and Limitations of Both Approaches

Machine learning models often face challenges such as data dependency, overfitting, and lack of interpretability, making it difficult to generalize results beyond training datasets. Classical modeling struggles with limited flexibility, relying heavily on predefined equations and assumptions that may not capture complex systems accurately. Both approaches encounter limitations in handling noisy data, scalability issues, and the balance between model complexity and computational efficiency.

Future Perspectives and Integration of Modeling Strategies

Future perspectives in machine learning emphasize its adaptability and scalability in handling big data, enabling continuous improvement through self-learning algorithms. Classical modeling remains crucial for interpretability and incorporation of domain knowledge, providing transparent decision-making frameworks. Integration of machine learning with classical models fosters hybrid approaches, leveraging the strengths of both techniques to enhance predictive accuracy and robustness across diverse applications.

Data-driven modeling

Data-driven modeling in machine learning leverages large datasets to automatically learn patterns and improve predictions, whereas classical modeling relies on predefined mathematical assumptions and expert knowledge.

Physics-based modeling

Physics-based modeling leverages fundamental physical laws for accurate system representation, while machine learning relies on data-driven algorithms to identify patterns without explicit physical understanding.

Model interpretability

Machine learning models often trade off interpretability for predictive accuracy, while classical modeling techniques prioritize transparent, easily interpretable relationships between variables.

Surrogate modeling

Surrogate modeling leverages machine learning algorithms to efficiently approximate complex simulations, offering faster and more flexible alternatives to classical modeling techniques that rely on explicit mathematical formulations.

Feature engineering

Machine learning automates feature engineering by extracting patterns from raw data, while classical modeling relies heavily on manual feature selection and domain expertise to create meaningful predictors.

Computational fluid dynamics (CFD)

Machine learning enhances Computational Fluid Dynamics (CFD) by enabling faster and more accurate predictive modeling compared to traditional classical modeling techniques.

Grey-box modeling

Grey-box modeling integrates machine learning algorithms with classical modeling techniques to combine data-driven adaptability and physical interpretability, enhancing predictive accuracy and model transparency.

Process optimization

Machine learning enhances process optimization by automatically identifying complex patterns and adapting models in real-time, whereas classical modeling relies on predefined equations and expert-driven assumptions with limited adaptability.

Hyperparameter tuning

Hyperparameter tuning in machine learning involves automated optimization of model parameters for enhanced predictive accuracy, whereas classical modeling relies on manual parameter selection based on domain expertise and heuristic methods.

First-principles equations

Machine learning leverages data-driven algorithms to predict outcomes without explicit physical laws, whereas classical modeling relies on first-principles equations derived from fundamental physics to describe system behaviors accurately.

Machine learning vs Classical modeling Infographic

njnir.com

njnir.com