CFD modeling in chemical engineering offers precise simulations of fluid flow and reaction kinetics, enabling detailed predictions of process behavior under varied conditions. While experimental data provide essential validation and capture real-world complexities, CFD reduces reliance on costly and time-consuming physical trials. Integrating CFD results with experimental observations enhances process optimization and scale-up accuracy.

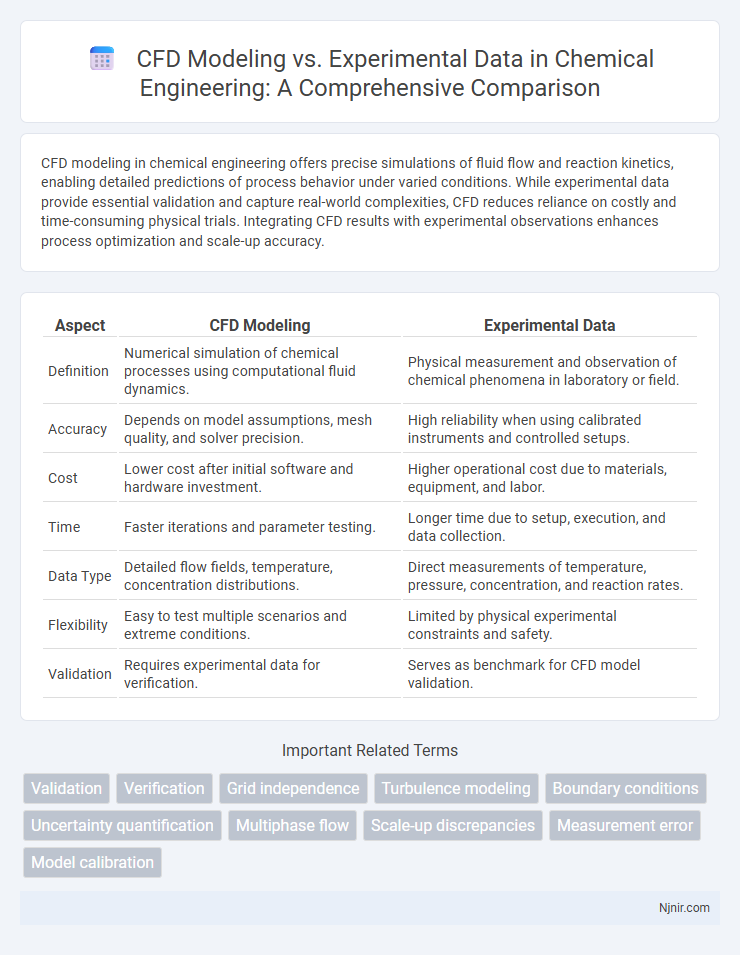

Table of Comparison

| Aspect | CFD Modeling | Experimental Data |

|---|---|---|

| Definition | Numerical simulation of chemical processes using computational fluid dynamics. | Physical measurement and observation of chemical phenomena in laboratory or field. |

| Accuracy | Depends on model assumptions, mesh quality, and solver precision. | High reliability when using calibrated instruments and controlled setups. |

| Cost | Lower cost after initial software and hardware investment. | Higher operational cost due to materials, equipment, and labor. |

| Time | Faster iterations and parameter testing. | Longer time due to setup, execution, and data collection. |

| Data Type | Detailed flow fields, temperature, concentration distributions. | Direct measurements of temperature, pressure, concentration, and reaction rates. |

| Flexibility | Easy to test multiple scenarios and extreme conditions. | Limited by physical experimental constraints and safety. |

| Validation | Requires experimental data for verification. | Serves as benchmark for CFD model validation. |

Introduction to CFD Modeling and Experimental Methods

CFD modeling simulates fluid flow behavior through numerical analysis of governing equations, enabling detailed visualization of velocity, pressure, and temperature fields within complex geometries. Experimental methods rely on physical measurements using instruments like particle image velocimetry (PIV) and laser Doppler anemometry (LDA) to capture real-world flow characteristics and validate computational predictions. Integrating both approaches enhances accuracy by combining theoretical insights from CFD with empirical evidence from experiments.

Fundamental Principles of CFD in Chemical Engineering

Computational Fluid Dynamics (CFD) modeling in chemical engineering relies on solving the Navier-Stokes equations to simulate fluid flow, heat transfer, and mass transfer phenomena based on fundamental conservation laws of mass, momentum, and energy. Experimental data serves as a critical benchmark to validate CFD simulations by providing real-world measurements of velocity fields, temperature distributions, and species concentration profiles within reactors and process equipment. Accurate CFD predictions depend on proper turbulence modeling, mesh quality, and boundary condition specification, which are refined through continuous comparison with experimental observations to ensure reliable process design and optimization.

Experimental Techniques in Chemical Process Analysis

Experimental techniques in chemical process analysis provide critical validation data for CFD modeling by capturing real-time flow dynamics, temperature distribution, and concentration profiles within reactors and pipelines. Methods such as Particle Image Velocimetry (PIV), Laser Doppler Anemometry (LDA), and gas chromatography enable precise measurement of flow velocities, turbulence characteristics, and chemical species concentrations, enhancing the accuracy of CFD simulations. High-fidelity experimental data help identify discrepancies in model assumptions, ensuring more reliable predictions of reaction kinetics and mass transfer phenomena in complex chemical processes.

Comparative Accuracy: CFD Predictions vs. Experimental Results

CFD modeling provides detailed flow dynamics predictions with high spatial and temporal resolution, yet its accuracy strongly depends on turbulence models and boundary condition assumptions. Experimental data offers direct measurements that capture real-world complexities but may be limited by measurement errors and experimental constraints. Comparative studies show CFD predictions often align within 5-15% of experimental results, highlighting its effectiveness for performance estimation while validating CFD with experiments ensures reliability.

Strengths and Limitations of CFD Modeling

CFD modeling offers precise simulation of complex fluid dynamics and heat transfer phenomena, enabling detailed analysis that is often impractical in physical experiments. Its strengths include cost-effectiveness, flexibility in testing multiple scenarios, and the ability to visualize flow patterns and quantify variables with high spatial and temporal resolution. Limitations arise from reliance on turbulence models and boundary conditions that may introduce inaccuracies, computational expense for high-fidelity simulations, and challenges in validating results without experimental data benchmarks.

Key Challenges in Experimental Data Acquisition

Experimental data acquisition in fluid dynamics faces key challenges such as measurement inaccuracies due to sensor limitations and environmental noise, which can lead to discrepancies when validating CFD models. Achieving high spatial and temporal resolution is difficult in turbulent flows, causing incomplete or sparse datasets that hinder accurate comparison. Complex flow phenomena like multiphase interactions and transient behaviors further complicate data capture, increasing uncertainty and limiting the reliability of experimental benchmarks.

Case Studies: CFD Validation with Experimental Data

CFD validation with experimental data in case studies demonstrates the accuracy and reliability of computational fluid dynamics models by comparing simulation results with physical measurements. Discrepancies between CFD predictions and experimental data highlight areas for model refinement, such as turbulence modeling and boundary condition settings. Successful case studies showcase improved predictive capabilities, enhancing the design and optimization of engineering systems across aerospace, automotive, and environmental applications.

Factors Influencing Discrepancies between CFD and Experiments

Discrepancies between CFD modeling and experimental data primarily arise from simplifications in turbulence modeling, mesh resolution limitations, and boundary condition approximations. Inaccurate representation of physical phenomena such as heat transfer, chemical reactions, or fluid-structure interactions also contributes to divergence. Experimental uncertainties, including measurement errors and sensor placement, further influence the comparison accuracy between CFD predictions and actual results.

Improving CFD Reliability through Experimental Calibration

Improving CFD reliability hinges on systematic experimental calibration to reduce model uncertainties and align simulations with real-world phenomena. Calibration data from wind tunnel tests, flow visualization, or sensor measurements enable parameter tuning and validation of turbulence models, boundary conditions, and numerical schemes in CFD. This integration enhances prediction accuracy for complex fluid dynamics, ensuring CFD outputs are robust, credible, and applicable for engineering design and analysis.

Future Perspectives in CFD-Experimental Integration

Future perspectives in CFD-experimental integration emphasize enhanced data assimilation techniques that improve model accuracy by incorporating real-time experimental measurements. Advanced machine learning algorithms are being developed to optimize the calibration of CFD simulations based on high-resolution experimental datasets, enabling more reliable predictions in complex fluid dynamics scenarios. The synergy between increasingly sophisticated experimental diagnostics and high-performance computational resources is expected to drive breakthroughs in predictive modeling and design optimization across aerospace, automotive, and energy sectors.

Validation

Validation of CFD modeling is essential to ensure accuracy by comparing simulation results against precise experimental data under controlled conditions.

Verification

Verification in CFD modeling ensures numerical accuracy and consistency by systematically comparing simulated results against experimental data to identify and minimize computational errors.

Grid independence

Grid independence in CFD modeling ensures accurate simulation results by minimizing numerical errors, enabling reliable comparison with experimental data for validation and analysis.

Turbulence modeling

CFD turbulence modeling accuracy varies significantly depending on the chosen model, with Reynolds-Averaged Navier-Stokes (RANS) models providing faster results but less precision compared to Large Eddy Simulation (LES), which offers closer alignment with experimental turbulence data at higher computational costs.

Boundary conditions

Accurate CFD modeling depends on precisely defined boundary conditions, which critically affect the correlation and reliability when compared to experimental data.

Uncertainty quantification

Comparing CFD modeling and experimental data requires rigorous uncertainty quantification techniques such as statistical analysis of model input parameters, sensitivity analysis, and validation metrics to ensure accuracy and reliability in predictive simulations.

Multiphase flow

CFD modeling of multiphase flow provides detailed phase interaction insights and predictive capabilities that complement experimental data by enabling analysis under varying conditions and scales difficult to replicate physically.

Scale-up discrepancies

Scale-up discrepancies between CFD modeling and experimental data often arise due to differences in turbulence modeling, mesh resolution, and boundary condition assumptions affecting flow behavior predictions.

Measurement error

CFD modeling accuracy is often limited by measurement error in experimental data, which can introduce uncertainties that affect the validation and calibration of simulation results.

Model calibration

Model calibration aligns CFD modeling parameters with experimental data to enhance simulation accuracy and predictive reliability.

CFD modeling vs Experimental data Infographic

njnir.com

njnir.com