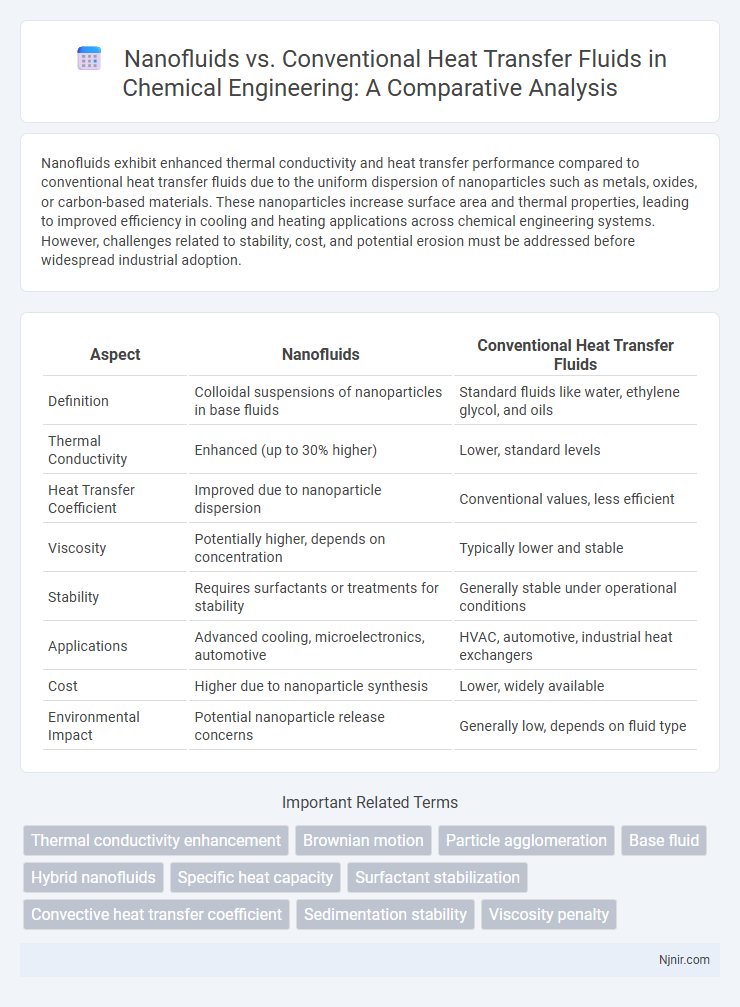

Nanofluids exhibit enhanced thermal conductivity and heat transfer performance compared to conventional heat transfer fluids due to the uniform dispersion of nanoparticles such as metals, oxides, or carbon-based materials. These nanoparticles increase surface area and thermal properties, leading to improved efficiency in cooling and heating applications across chemical engineering systems. However, challenges related to stability, cost, and potential erosion must be addressed before widespread industrial adoption.

Table of Comparison

| Aspect | Nanofluids | Conventional Heat Transfer Fluids |

|---|---|---|

| Definition | Colloidal suspensions of nanoparticles in base fluids | Standard fluids like water, ethylene glycol, and oils |

| Thermal Conductivity | Enhanced (up to 30% higher) | Lower, standard levels |

| Heat Transfer Coefficient | Improved due to nanoparticle dispersion | Conventional values, less efficient |

| Viscosity | Potentially higher, depends on concentration | Typically lower and stable |

| Stability | Requires surfactants or treatments for stability | Generally stable under operational conditions |

| Applications | Advanced cooling, microelectronics, automotive | HVAC, automotive, industrial heat exchangers |

| Cost | Higher due to nanoparticle synthesis | Lower, widely available |

| Environmental Impact | Potential nanoparticle release concerns | Generally low, depends on fluid type |

Introduction to Heat Transfer Fluids in Chemical Engineering

Heat transfer fluids in chemical engineering are crucial for efficient thermal management and process control, with conventional fluids like water, oil, and ethylene glycol widely used for their established thermal properties and cost-effectiveness. Nanofluids, engineered by dispersing nanoparticles such as metals, oxides, or carbides in base fluids, exhibit enhanced thermal conductivity and heat transfer coefficients compared to traditional fluids. These improvements can lead to increased process efficiency, reduced energy consumption, and better temperature regulation in critical chemical engineering applications.

Defining Nanofluids: Composition and Properties

Nanofluids are engineered colloidal suspensions of nanoparticles, typically 1-100 nm in size, dispersed in conventional heat transfer fluids such as water, ethylene glycol, or oil, enhancing thermal conductivity and heat transfer rates. The nanoparticles, made from metals, oxides, carbides, or carbon nanotubes, significantly alter the base fluid's thermal properties, viscosity, and stability. These enhanced properties lead to improved heat transfer performance compared to conventional fluids, which rely solely on their intrinsic thermal characteristics without nanoparticle additives.

Conventional Heat Transfer Fluids: Types and Characteristics

Conventional heat transfer fluids include water, glycol mixtures, oils, and molten salts, each offering distinct thermal properties suited to specific applications. Water is widely used due to its high specific heat capacity and thermal conductivity, while glycol mixtures provide freeze protection in refrigeration systems. Oils and molten salts deliver higher operating temperature ranges and good thermal stability, making them ideal for industrial and solar thermal energy storage applications.

Thermal Conductivity: Nanofluids vs Conventional Fluids

Nanofluids exhibit significantly higher thermal conductivity compared to conventional heat transfer fluids due to the inclusion of nanoparticles such as copper, aluminum oxide, or carbon nanotubes suspended within the base fluid. This enhancement in thermal conductivity improves heat transfer efficiency, often resulting in up to 30-40% better thermal performance than traditional fluids like water or ethylene glycol. The increased surface area and improved heat capacity of nanofluids make them ideal for advanced cooling systems in electronics, automotive, and industrial applications.

Viscosity and Flow Behavior Comparison

Nanofluids exhibit significantly higher viscosity compared to conventional heat transfer fluids, primarily due to the suspended nanoparticles altering the fluid's microstructure. This increase in viscosity influences flow behavior by enhancing resistance to shear stress and modifying turbulence characteristics, which can affect pump power requirements and heat transfer efficiency. Unlike conventional fluids that display near-Newtonian behavior, nanofluids often demonstrate non-Newtonian flow properties, necessitating careful consideration in thermal system design to optimize performance.

Stability and Dispersion of Nanoparticles

Nanofluids exhibit enhanced thermal conductivity compared to conventional heat transfer fluids, primarily due to the stable suspension and uniform dispersion of nanoparticles within the base fluid. Stability is crucial as nanoparticle agglomeration can lead to sedimentation, reducing heat transfer efficiency and causing operational issues. Techniques such as surface functionalization and ultrasonic agitation improve dispersion and maintain long-term stability, making nanofluids superior for advanced thermal management applications.

Heat Transfer Efficiency in Industrial Applications

Nanofluids exhibit significantly higher heat transfer efficiency compared to conventional heat transfer fluids due to their enhanced thermal conductivity and improved convective heat transfer properties. Industrial applications benefit from nanofluids by achieving increased cooling rates, reduced energy consumption, and improved system performance in heat exchangers, engines, and electronic cooling systems. Empirical studies indicate that nanofluids can enhance heat transfer coefficients by up to 30-40% over traditional fluids like water, ethylene glycol, or oil, making them ideal for advanced thermal management solutions.

Corrosion and Environmental Impacts

Nanofluids, engineered with nanoparticles such as metal oxides or carbon-based materials, exhibit enhanced heat transfer properties compared to conventional fluids like water or glycol, while also potentially reducing corrosion rates due to their improved thermal conductivity and stability. Conventional heat transfer fluids often face challenges including chemical degradation and higher corrosion risks within metal piping systems, necessitating frequent maintenance and replacement. Environmentally, nanofluids offer opportunities for reduced fluid volumes and lower energy consumption, but their long-term ecological impact requires comprehensive assessment due to potential nanoparticle release, whereas conventional fluids' biodegradability and toxicity profiles are better understood.

Economic and Operational Considerations

Nanofluids exhibit superior thermal conductivity and heat transfer efficiency compared to conventional heat transfer fluids, leading to reduced energy consumption and operational costs in industrial applications. The higher manufacturing and material costs of nanofluids can be offset by their enhanced heat transfer rates, which decrease the size and energy requirements of heat exchangers. Maintenance expenses may be lower due to nanofluids' improved stability and reduced fouling compared to traditional fluids, but system compatibility and long-term reliability remain critical economic factors for adoption.

Future Trends and Research Directions

Nanofluids exhibit superior thermal conductivity and heat transfer efficiency compared to conventional heat transfer fluids, driving significant interest in future research focused on optimizing nanoparticle dispersion, stability, and environmental impact. Emerging trends emphasize the development of hybrid nanofluids combining different nanoparticles to tailor thermal properties, alongside advanced computational modeling for predicting heat transfer performance under various operating conditions. Research is also directed towards scalable production methods and integration of nanofluids in renewable energy systems, enhancing sustainability and energy efficiency in industrial and electronic cooling applications.

Thermal conductivity enhancement

Nanofluids enhance thermal conductivity by up to 40% compared to conventional heat transfer fluids, improving heat transfer efficiency in cooling and heating applications.

Brownian motion

Nanofluids enhance heat transfer efficiency compared to conventional fluids primarily due to intensified Brownian motion of suspended nanoparticles, which increases thermal conductivity and energy dispersion at the microscale.

Particle agglomeration

Nanofluids exhibit enhanced thermal conductivity compared to conventional heat transfer fluids but face challenges due to particle agglomeration, which reduces stability and heat transfer efficiency.

Base fluid

Nanofluids enhance thermal conductivity and heat transfer efficiency compared to conventional heat transfer fluids primarily due to the suspension of nanoparticles within the base fluid, which significantly improves its thermal properties.

Hybrid nanofluids

Hybrid nanofluids, combining multiple nanoparticles, exhibit significantly enhanced thermal conductivity and heat transfer performance compared to conventional and single-component nanofluids, making them highly efficient for advanced cooling and heating applications.

Specific heat capacity

Nanofluids exhibit lower specific heat capacity than conventional heat transfer fluids, but their enhanced thermal conductivity often results in superior overall heat transfer performance.

Surfactant stabilization

Surfactant stabilization significantly enhances the dispersion and thermal conductivity of nanofluids compared to conventional heat transfer fluids, improving heat transfer efficiency and stability.

Convective heat transfer coefficient

Nanofluids exhibit significantly higher convective heat transfer coefficients than conventional heat transfer fluids due to enhanced thermal conductivity and improved nanoparticle-induced turbulence.

Sedimentation stability

Nanofluids exhibit superior sedimentation stability compared to conventional heat transfer fluids due to their enhanced nanoparticle dispersion and reduced particle agglomeration.

Viscosity penalty

Nanofluids exhibit higher viscosity than conventional heat transfer fluids, resulting in increased pumping power requirements and potential viscosity penalties that may offset their enhanced thermal conductivity benefits.

Nanofluids vs Conventional heat transfer fluids Infographic

njnir.com

njnir.com