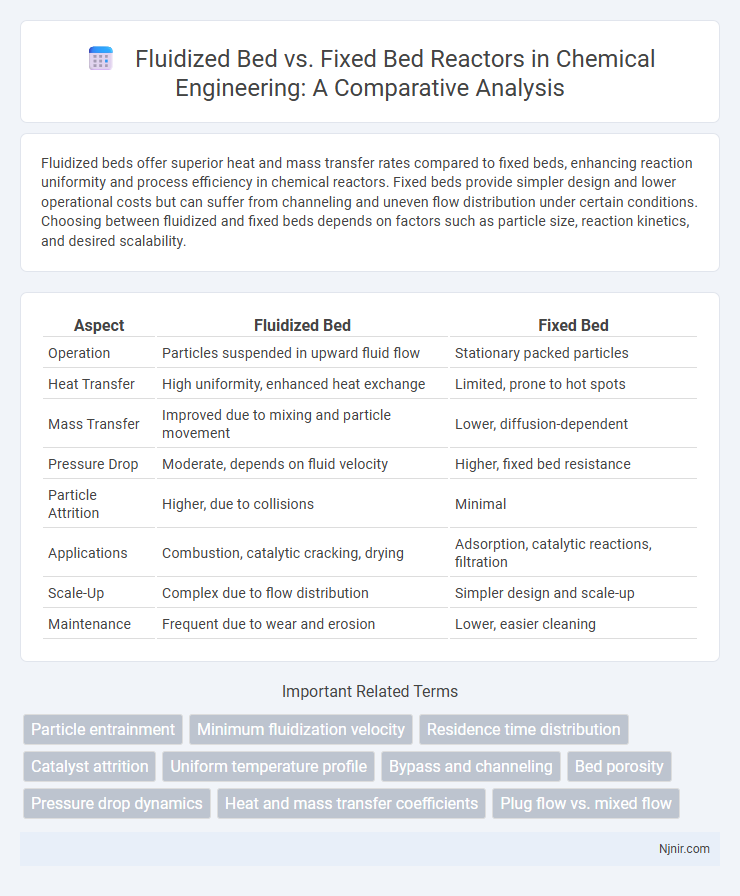

Fluidized beds offer superior heat and mass transfer rates compared to fixed beds, enhancing reaction uniformity and process efficiency in chemical reactors. Fixed beds provide simpler design and lower operational costs but can suffer from channeling and uneven flow distribution under certain conditions. Choosing between fluidized and fixed beds depends on factors such as particle size, reaction kinetics, and desired scalability.

Table of Comparison

| Aspect | Fluidized Bed | Fixed Bed |

|---|---|---|

| Operation | Particles suspended in upward fluid flow | Stationary packed particles |

| Heat Transfer | High uniformity, enhanced heat exchange | Limited, prone to hot spots |

| Mass Transfer | Improved due to mixing and particle movement | Lower, diffusion-dependent |

| Pressure Drop | Moderate, depends on fluid velocity | Higher, fixed bed resistance |

| Particle Attrition | Higher, due to collisions | Minimal |

| Applications | Combustion, catalytic cracking, drying | Adsorption, catalytic reactions, filtration |

| Scale-Up | Complex due to flow distribution | Simpler design and scale-up |

| Maintenance | Frequent due to wear and erosion | Lower, easier cleaning |

Introduction to Fluidized Bed and Fixed Bed Reactors

Fluidized bed reactors utilize a dynamic bed of solid particles suspended by an upward flow of gas or liquid, enhancing mixing and heat transfer, which is ideal for catalytic reactions and combustion processes. Fixed bed reactors consist of a packed bed of catalyst particles through which reactants flow in a steady, immobile phase, favored for processes requiring precise control over contact time and temperature gradients. Fluidized beds offer superior mass and heat transfer rates compared to the relatively simple design and operational stability of fixed bed reactors.

Fundamental Principles of Fluidized Bed Systems

Fluidized bed systems operate by suspending solid particles in an upward-flowing fluid, creating a dynamic, fluid-like state that enhances heat and mass transfer. This principle contrasts with fixed bed systems, where the solid particles remain stationary, and the fluid flows through the packed bed, resulting in limited mixing and lower heat transfer efficiency. The fluidization velocity and particle properties are critical factors determining the regime and performance of a fluidized bed reactor.

Core Concepts of Fixed Bed Reactor Design

Fixed bed reactor design centers on a stationary catalyst or solid phase through which reactants flow, ensuring uniform contact and efficient reaction rates. Key parameters include catalyst packing density, flow distribution, temperature gradients, and pressure drop, which directly influence conversion efficiency and selectivity. Heat management and mass transfer limitations are critical challenges addressed through careful reactor dimensioning and catalyst pellet size optimization.

Fluid Dynamics: Comparison between Fluidized and Fixed Beds

Fluidized beds exhibit superior fluid dynamics due to enhanced gas-solid contact and uniform particle suspension, resulting in improved mass and heat transfer compared to fixed beds. In fixed beds, gas flow is restricted by static particles, causing higher pressure drop and non-uniform flow distribution. The turbulence and mixing in fluidized beds lead to better reaction efficiency and decreased channeling effects, optimizing overall process performance.

Heat and Mass Transfer Efficiency

Fluidized bed reactors exhibit superior heat and mass transfer efficiency compared to fixed bed reactors due to enhanced particle mixing and increased surface area contact with the fluidizing medium. The turbulent motion in fluidized beds promotes uniform temperature distribution and rapid diffusion rates, resulting in improved reaction kinetics. Fixed bed reactors often suffer from channeling and temperature gradients, limiting effective heat and mass transfer performance in industrial applications.

Operational Advantages and Limitations

Fluidized beds offer superior heat and mass transfer rates due to enhanced particle mixing, enabling uniform temperature distribution and higher reaction efficiencies compared to fixed beds. However, fluidized beds require higher energy input for fluidization and can face challenges like particle attrition and erosion. Fixed beds provide simpler operation and lower operational costs but suffer from channeling, poor temperature control, and limited scalability in processes involving heterogeneous reactions.

Industrial Applications and Suitability

Fluidized bed reactors excel in industrial applications requiring enhanced heat and mass transfer, such as catalytic cracking, combustion, and chemical synthesis, due to their superior mixing and temperature uniformity. Fixed bed reactors are preferred in processes like gas purification, hydrogenation, and adsorption where stable catalyst placement and lower operational complexity are critical. Suitability depends on factors like catalyst sensitivity, reaction kinetics, scalability, and ease of maintenance, with fluidized beds favored for large-scale, highly exothermic reactions and fixed beds chosen for simpler, steady-state processes.

Catalyst Performance and Lifespan

Fluidized beds enhance catalyst performance by promoting uniform temperature distribution and improved mass transfer, which reduces hot spots and catalyst deactivation compared to fixed beds. Fixed bed reactors often experience channeling and poor heat removal, leading to faster catalyst degradation and shorter lifespan. The dynamic movement in fluidized beds helps maintain catalyst activity longer, extending operational cycles and reducing replacement frequency.

Scale-Up Considerations and Challenges

Scaling up fluidized bed reactors requires careful management of uniform gas distribution and particle fluidization to maintain consistent heat and mass transfer characteristics, which are crucial for preventing channeling and agglomeration issues. Fixed bed scale-up challenges primarily involve ensuring even flow distribution and avoiding hotspots due to limited convection, impacting catalyst performance and lifespan. Both reactor types demand precise control of operational parameters and reactor design to achieve scalability while maintaining process efficiency and product quality.

Economic and Environmental Impacts

Fluidized bed reactors typically offer higher energy efficiency and lower operating costs due to enhanced heat and mass transfer, leading to improved reaction rates compared to fixed bed reactors. Economically, fluidized beds reduce catalyst deactivation and maintenance expenses, while fixed beds often incur higher costs related to pressure drop and catalyst replacement. Environmentally, fluidized beds minimize emissions and optimize fuel usage because of better temperature control and uniform gas-solid contact, whereas fixed beds can generate hotspots that increase pollutant formation and energy consumption.

Particle entrainment

Fluidized beds exhibit higher particle entrainment due to vigorous particle suspension and gas flow, whereas fixed beds have minimal entrainment because particles remain stationary and tightly packed.

Minimum fluidization velocity

Minimum fluidization velocity is lower in fluidized beds compared to fixed beds, enabling efficient particle suspension and enhanced mass transfer in fluidized bed reactors.

Residence time distribution

Fluidized beds exhibit broader residence time distributions due to enhanced mixing, while fixed beds demonstrate narrower, more uniform residence times because of their static particle arrangement.

Catalyst attrition

Fluidized bed reactors exhibit higher catalyst attrition rates due to intense particle collisions and abrasion compared to fixed bed reactors, where catalyst particles remain stationary and experience lower mechanical stress.

Uniform temperature profile

Fluidized bed reactors maintain a more uniform temperature profile than fixed bed reactors due to enhanced mixing and heat transfer properties.

Bypass and channeling

Fluidized beds minimize bypass and channeling through uniform particle suspension, while fixed beds are prone to these issues due to uneven flow paths and stagnant zones.

Bed porosity

Fluidized beds exhibit higher bed porosity compared to fixed beds, enhancing gas-solid contact efficiency and mass transfer rates.

Pressure drop dynamics

Fluidized beds exhibit lower and more stable pressure drop dynamics due to particle suspension and uniform gas flow compared to fixed beds, where pressure drop increases sharply with flow rate because of static packing and channeling effects.

Heat and mass transfer coefficients

Fluidized beds exhibit significantly higher heat and mass transfer coefficients compared to fixed beds due to enhanced particle mixing and increased fluid-solid contact surface area.

Plug flow vs. mixed flow

Fluidized beds exhibit mixed flow behavior enhancing mass and heat transfer, whereas fixed beds demonstrate plug flow characteristics ensuring uniform residence time distribution.

Fluidized bed vs Fixed bed Infographic

njnir.com

njnir.com