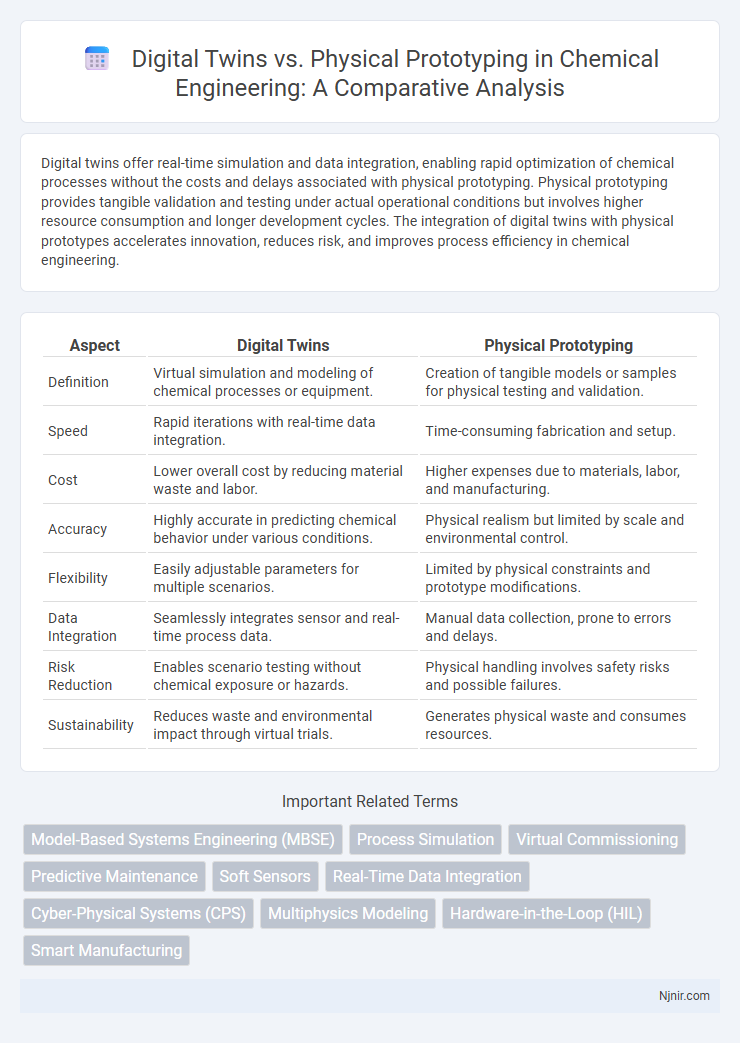

Digital twins offer real-time simulation and data integration, enabling rapid optimization of chemical processes without the costs and delays associated with physical prototyping. Physical prototyping provides tangible validation and testing under actual operational conditions but involves higher resource consumption and longer development cycles. The integration of digital twins with physical prototypes accelerates innovation, reduces risk, and improves process efficiency in chemical engineering.

Table of Comparison

| Aspect | Digital Twins | Physical Prototyping |

|---|---|---|

| Definition | Virtual simulation and modeling of chemical processes or equipment. | Creation of tangible models or samples for physical testing and validation. |

| Speed | Rapid iterations with real-time data integration. | Time-consuming fabrication and setup. |

| Cost | Lower overall cost by reducing material waste and labor. | Higher expenses due to materials, labor, and manufacturing. |

| Accuracy | Highly accurate in predicting chemical behavior under various conditions. | Physical realism but limited by scale and environmental control. |

| Flexibility | Easily adjustable parameters for multiple scenarios. | Limited by physical constraints and prototype modifications. |

| Data Integration | Seamlessly integrates sensor and real-time process data. | Manual data collection, prone to errors and delays. |

| Risk Reduction | Enables scenario testing without chemical exposure or hazards. | Physical handling involves safety risks and possible failures. |

| Sustainability | Reduces waste and environmental impact through virtual trials. | Generates physical waste and consumes resources. |

Introduction to Digital Twins and Physical Prototyping in Chemical Engineering

Digital twins in chemical engineering employ real-time data and simulations to create virtual replicas of physical processes, enhancing process optimization and predictive maintenance. Physical prototyping involves constructing tangible models or pilot plants to test chemical reactions and process equipment, providing direct insights into operational behavior. Integrating digital twins with physical prototyping accelerates design iterations and reduces costs in chemical process development.

Core Principles: Digital Twins vs Physical Prototyping

Digital twins integrate real-time data and IoT sensors to create dynamic virtual models that mirror physical assets, enabling continuous monitoring and predictive analysis. Physical prototyping relies on tangible, handcrafted models to test functionality and design, offering immediate tactile feedback but limited adaptability to real-time changes. The core principle of digital twins lies in their digital continuity and data-driven precision, while physical prototyping emphasizes empirical validation through physical interaction.

Design and Simulation Capabilities

Digital twins offer advanced design and simulation capabilities by creating virtual replicas that enable real-time testing and iterative optimization without physical resource constraints. Physical prototyping provides tangible models for hands-on evaluation but lacks the speed and flexibility of digital simulations in exploring multiple design scenarios. Leveraging digital twins accelerates development cycles and enhances precision through continuous data integration and predictive analytics.

Cost and Resource Efficiency Comparison

Digital twins significantly reduce development costs by enabling virtual testing and iteration without the need for expensive physical materials or manufacturing setups. Physical prototyping often demands substantial investments in raw materials, labor, and time, increasing overall project expenses and resource consumption. By leveraging real-time data and simulation, digital twins optimize resource allocation and minimize waste, resulting in enhanced cost and resource efficiency compared to traditional physical prototyping methods.

Real-time Monitoring and Data Integration

Digital twins enable real-time monitoring by creating dynamic virtual replicas of physical assets that integrate sensor data continuously for immediate analysis and decision-making. Physical prototyping lacks this continuous data integration, relying instead on intermittent testing phases, which limits the ability to detect issues or optimize performance instantaneously. Real-time monitoring in digital twins enhances predictive maintenance, operational efficiency, and iterative design improvements unmatched by traditional physical prototypes.

Scalability and Flexibility in Process Development

Digital twins enable unparalleled scalability by simulating multiple scenarios and iterating designs rapidly without the constraints of physical materials or space. Physical prototyping, while offering tangible insights, faces limitations in scalability due to time-intensive production and resource costs. In process development, the flexibility of digital twins allows real-time adjustments and data integration, enhancing optimization beyond what static physical prototypes can achieve.

Accuracy and Reliability of Results

Digital twins provide high accuracy by simulating real-world conditions through continuous data integration from IoT sensors, enabling precise predictions and iterative design improvements. Physical prototyping offers tangible validation with inherent material and environmental factors but may suffer from inconsistencies due to manufacturing variances and measurement errors. Combining digital twins with physical prototypes enhances reliability by using simulation data to refine models while verifying results through hands-on testing.

Impact on Innovation and Time-to-Market

Digital twins enable rapid iteration and real-time testing, significantly accelerating innovation cycles compared to traditional physical prototyping. By simulating product performance under various conditions, digital twins reduce the need for costly and time-consuming physical models, shortening time-to-market. Companies leveraging digital twins experience faster product development, enhanced design accuracy, and improved responsiveness to market demands.

Challenges and Limitations of Each Approach

Digital twins face challenges such as high initial costs, complex data integration, and reliance on accurate sensor inputs for real-time simulation, which can limit their effectiveness. Physical prototyping encounters limitations including time-consuming production, high material expenses, and difficulty in making rapid iterative changes. Both methods struggle with scalability and may require complementary use to overcome individual shortcomings in product development cycles.

Future Perspectives: The Evolving Role of Digital Twins in Chemical Engineering

Digital twins are revolutionizing chemical engineering by enabling real-time simulation and optimization of complex processes, which physical prototyping cannot achieve with the same speed and flexibility. Advances in AI, IoT, and big data analytics drive the evolving role of digital twins, allowing predictive maintenance, enhanced safety, and reduced operational costs in chemical plants. Future perspectives emphasize integrating digital twins with augmented reality and machine learning for autonomous plant management and accelerated innovation cycles in chemical engineering.

Model-Based Systems Engineering (MBSE)

Digital twins enhance Model-Based Systems Engineering (MBSE) by providing real-time data integration and simulation capabilities that surpass the static analysis of traditional physical prototyping.

Process Simulation

Digital twins enable real-time process simulation and iterative optimization, significantly reducing the time and cost compared to traditional physical prototyping methods.

Virtual Commissioning

Virtual commissioning using digital twins enables exhaustive system testing and error detection in a simulated environment, reducing costs and time compared to traditional physical prototyping.

Predictive Maintenance

Digital twins enable precise predictive maintenance by simulating real-time physical asset conditions, reducing downtime and costs compared to traditional physical prototyping.

Soft Sensors

Soft sensors in digital twins enable real-time, data-driven performance monitoring and predictive maintenance that outperforms traditional physical prototyping methods in speed and cost-efficiency.

Real-Time Data Integration

Digital twins enable real-time data integration by continuously synchronizing virtual models with physical prototypes, enhancing accuracy and accelerating design iterations compared to traditional physical prototyping.

Cyber-Physical Systems (CPS)

Digital twins enhance Cyber-Physical Systems (CPS) by enabling real-time data integration and simulation, offering faster, cost-effective, and more accurate alternatives to traditional physical prototyping.

Multiphysics Modeling

Multiphysics modeling in digital twins enables simultaneous simulation of thermal, structural, and fluid dynamics phenomena, offering faster, cost-effective, and highly accurate analysis compared to traditional physical prototyping.

Hardware-in-the-Loop (HIL)

Hardware-in-the-Loop (HIL) testing enhances digital twins by integrating real-time physical hardware interaction, offering faster, cost-effective validation over traditional physical prototyping in complex system development.

Smart Manufacturing

Digital twins enhance smart manufacturing by providing real-time data simulations that reduce costs and accelerate development compared to traditional physical prototyping.

Digital twins vs Physical prototyping Infographic

njnir.com

njnir.com