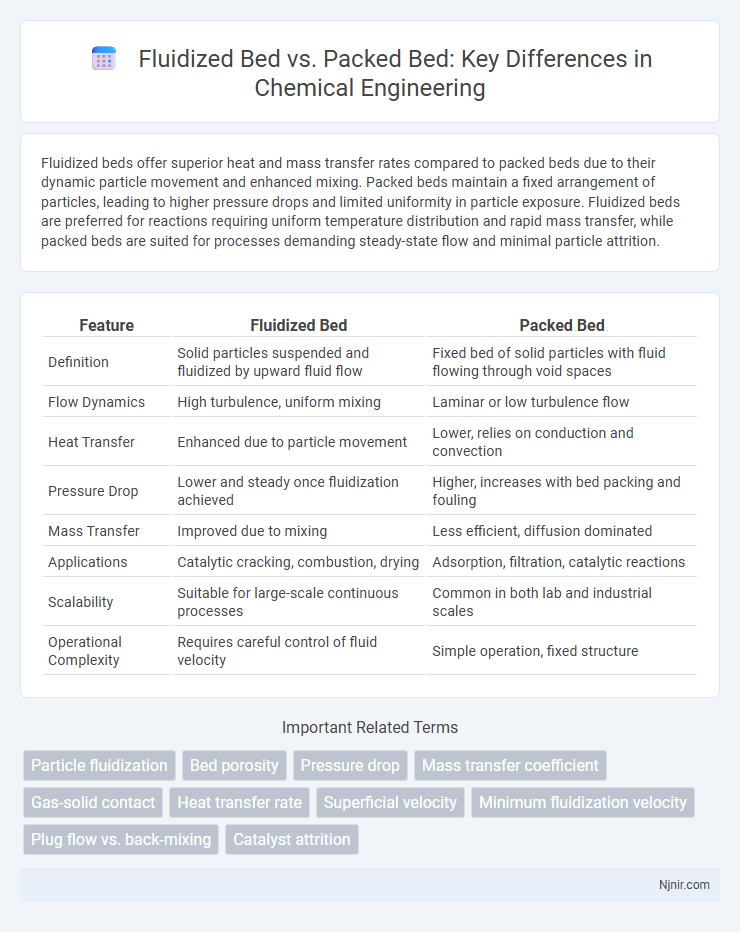

Fluidized beds offer superior heat and mass transfer rates compared to packed beds due to their dynamic particle movement and enhanced mixing. Packed beds maintain a fixed arrangement of particles, leading to higher pressure drops and limited uniformity in particle exposure. Fluidized beds are preferred for reactions requiring uniform temperature distribution and rapid mass transfer, while packed beds are suited for processes demanding steady-state flow and minimal particle attrition.

Table of Comparison

| Feature | Fluidized Bed | Packed Bed |

|---|---|---|

| Definition | Solid particles suspended and fluidized by upward fluid flow | Fixed bed of solid particles with fluid flowing through void spaces |

| Flow Dynamics | High turbulence, uniform mixing | Laminar or low turbulence flow |

| Heat Transfer | Enhanced due to particle movement | Lower, relies on conduction and convection |

| Pressure Drop | Lower and steady once fluidization achieved | Higher, increases with bed packing and fouling |

| Mass Transfer | Improved due to mixing | Less efficient, diffusion dominated |

| Applications | Catalytic cracking, combustion, drying | Adsorption, filtration, catalytic reactions |

| Scalability | Suitable for large-scale continuous processes | Common in both lab and industrial scales |

| Operational Complexity | Requires careful control of fluid velocity | Simple operation, fixed structure |

Introduction to Fluidized and Packed Bed Reactors

Fluidized bed reactors utilize a fluid to suspend solid catalyst particles, enhancing gas-solid contact and improving heat and mass transfer rates, which optimize reaction efficiency. Packed bed reactors consist of a fixed arrangement of solid catalyst particles through which fluid flows, offering simplicity and consistent flow patterns but limited mixing compared to fluidized beds. Fluidized beds are preferred for processes requiring high heat transfer and uniform temperature distribution, while packed beds are commonly used for catalytic reactions with stable flow conditions.

Fundamental Principles of Fluidized Beds

Fluidized beds operate on the principle of suspending solid particles in an upward flow of gas or liquid, creating a dynamic, fluid-like state that enhances heat and mass transfer. This contrasts with packed beds, where the fluid flows through a fixed, immobile bed of particles, resulting in higher pressure drops and less efficient mixing. The fundamental advantage of fluidized beds lies in their uniform temperature distribution and improved reaction rates due to the continuous movement and thorough contact between phases.

Key Characteristics of Packed Bed Systems

Packed bed systems feature a stationary arrangement of solid particles through which fluid flows, providing high surface area for heat and mass transfer. These systems exhibit low pressure drop, uniform flow distribution, and excellent catalyst support, making them ideal for chemical reactions and adsorption processes. Their compact design and ease of operation contribute to their widespread use in industrial applications such as filtration, gas absorption, and fixed-bed reactors.

Heat and Mass Transfer Performance Comparison

Fluidized beds exhibit superior heat and mass transfer rates compared to packed beds due to vigorous particle movement and enhanced mixing, resulting in higher interphase heat transfer coefficients often exceeding 500 W/m2K. Packed beds suffer from channeling and stagnant zones, leading to lower transfer efficiencies typically around 100-250 W/m2K. The dynamic fluidization in fluidized beds ensures uniform temperature distribution and reduced concentration gradients, optimizing reaction kinetics in catalytic or drying processes.

Pressure Drop Analysis: Fluidized vs Packed Beds

Pressure drop in packed beds is typically higher due to the fixed arrangement of solid particles, causing greater resistance to fluid flow and resulting in increased energy consumption. Fluidized beds exhibit lower pressure drops as the solids are suspended and mobile, reducing flow constriction and enabling more uniform fluid distribution. Accurate pressure drop analysis in both systems is crucial for optimizing operational efficiency and minimizing costs in chemical reactors and filtration processes.

Catalyst Utilization and Efficiency

Fluidized beds offer superior catalyst utilization by ensuring uniform catalyst particle movement and improved gas-solid contact, which enhances reaction rates and minimizes hotspots. Packed beds typically experience channeling and uneven flow distribution, leading to suboptimal catalyst efficiency and localized deactivation. The enhanced mixing in fluidized beds results in higher catalytic activity and prolonged catalyst lifespan compared to packed bed reactors.

Operational Flexibility and Scalability

Fluidized beds offer superior operational flexibility by allowing easy adjustment of gas flow rates to accommodate varying reaction conditions and feedstock types, promoting uniform temperature distribution and efficient mixing. Packed beds provide limited scalability due to channeling and pressure drop issues that escalate with increased reactor size, restricting operational adjustments. Fluidized bed systems enable seamless scaling through modular design and maintain consistent performance across different scales, making them preferable for dynamic industrial processes.

Common Industrial Applications

Fluidized beds are widely used in catalytic cracking, combustion, and drying processes due to their superior heat and mass transfer capabilities and uniform temperature distribution. Packed beds are commonly employed in chemical reactors, adsorption columns, and filtration systems where high pressure drop and fixed particle arrangements enhance separation and reaction efficiency. Industries such as petrochemical, pharmaceutical, and environmental engineering rely on these reactors for processes like gas-solid reactions, pollutant removal, and fluid filtration.

Maintenance and Fouling Considerations

Fluidized beds exhibit lower fouling tendencies due to their continuous particle movement, which naturally scours surfaces and minimizes buildup, resulting in reduced cleaning frequency and easier maintenance. Packed beds, however, are prone to channeling and clogging caused by particulate accumulation, increasing pressure drop and necessitating more frequent maintenance interventions to prevent operational inefficiencies. Effective maintenance strategies for fluidized beds focus on monitoring particle quality and flow rates, while packed beds require regular inspection and cleaning to manage fouling and sustain optimal performance.

Selection Criteria for Reactor Design

Selection criteria for fluidized bed and packed bed reactors depend on factors such as heat and mass transfer efficiency, pressure drop, and particle size distribution. Fluidized beds offer superior mixing and temperature uniformity, making them ideal for reactions requiring enhanced heat transfer and handling of fine or irregular particles. Packed beds provide higher catalytic surface area and lower attrition, suited for processes demanding steady flow and minimal particle movement under moderate pressure drops.

Particle fluidization

Particle fluidization in fluidized beds enables enhanced mass transfer and efficient mixing compared to the static particle arrangement and limited contact surface in packed beds.

Bed porosity

Fluidized beds exhibit higher bed porosity compared to packed beds due to particle suspension in the fluid phase, enhancing mass and heat transfer rates.

Pressure drop

Fluidized beds exhibit lower and more stable pressure drop compared to packed beds, where pressure drop increases significantly with particle size and flow rate.

Mass transfer coefficient

Fluidized beds exhibit higher mass transfer coefficients than packed beds due to enhanced particle mixing and increased interfacial area.

Gas-solid contact

Fluidized beds provide superior gas-solid contact efficiency compared to packed beds due to enhanced particle suspension and increased surface area exposure.

Heat transfer rate

Fluidized beds exhibit significantly higher heat transfer rates than packed beds due to enhanced particle-fluid contact and improved mixing dynamics.

Superficial velocity

Superficial velocity in fluidized beds is higher than in packed beds, enabling particle suspension and enhanced mass transfer efficiency.

Minimum fluidization velocity

Minimum fluidization velocity (Umf) in fluidized beds is the critical gas velocity at which particles transition from a packed bed state to a fluidized state, enabling enhanced mixing and heat transfer compared to a fixed packed bed.

Plug flow vs. back-mixing

Fluidized beds exhibit near-plug flow behavior with minimal back-mixing, enhancing uniform particle suspension and heat transfer, whereas packed beds tend to have significant back-mixing due to stagnant zones, resulting in less ideal plug flow characteristics.

Catalyst attrition

Fluidized beds exhibit higher catalyst attrition rates compared to packed beds due to increased particle collisions and mechanical stress during operation.

fluidized bed vs packed bed Infographic

njnir.com

njnir.com