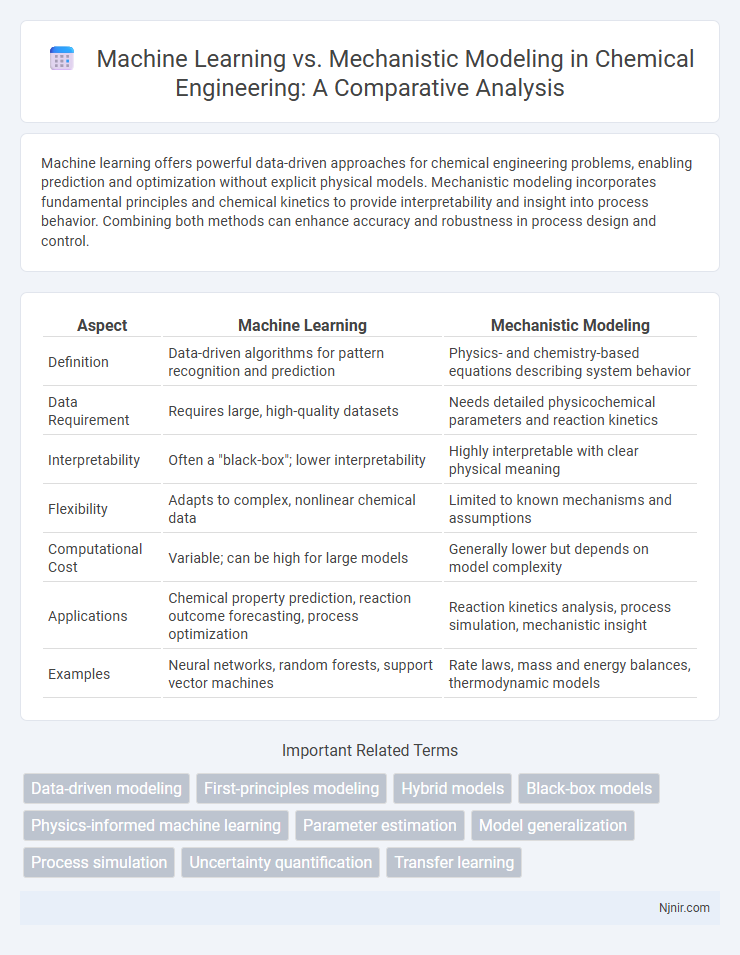

Machine learning offers powerful data-driven approaches for chemical engineering problems, enabling prediction and optimization without explicit physical models. Mechanistic modeling incorporates fundamental principles and chemical kinetics to provide interpretability and insight into process behavior. Combining both methods can enhance accuracy and robustness in process design and control.

Table of Comparison

| Aspect | Machine Learning | Mechanistic Modeling |

|---|---|---|

| Definition | Data-driven algorithms for pattern recognition and prediction | Physics- and chemistry-based equations describing system behavior |

| Data Requirement | Requires large, high-quality datasets | Needs detailed physicochemical parameters and reaction kinetics |

| Interpretability | Often a "black-box"; lower interpretability | Highly interpretable with clear physical meaning |

| Flexibility | Adapts to complex, nonlinear chemical data | Limited to known mechanisms and assumptions |

| Computational Cost | Variable; can be high for large models | Generally lower but depends on model complexity |

| Applications | Chemical property prediction, reaction outcome forecasting, process optimization | Reaction kinetics analysis, process simulation, mechanistic insight |

| Examples | Neural networks, random forests, support vector machines | Rate laws, mass and energy balances, thermodynamic models |

Introduction to Machine Learning and Mechanistic Modeling in Chemical Engineering

Machine learning in chemical engineering leverages algorithms to identify patterns and predict outcomes from vast experimental data, enabling rapid optimization of processes and materials. Mechanistic modeling relies on fundamental physical and chemical principles, formulating differential equations to describe reaction kinetics, mass transfer, and thermodynamics within systems. Combining machine learning with mechanistic models enhances predictive accuracy, facilitating advanced process design and control in chemical engineering applications.

Fundamental Principles of Machine Learning Approaches

Machine learning approaches rely on data-driven algorithms that identify patterns and make predictions without explicit, predefined rules, contrasting mechanistic models which are based on established physical or biological principles. Core principles of machine learning include supervised learning, unsupervised learning, and reinforcement learning, each utilizing statistical methods and optimization techniques to improve model accuracy. These approaches emphasize scalability, adaptability, and the ability to handle complex, high-dimensional datasets, enabling robust generalization beyond traditional mechanistic frameworks.

Core Concepts of Mechanistic Modeling Techniques

Mechanistic modeling techniques rely on mathematical representations of physical, chemical, or biological processes based on underlying principles, capturing system behavior through differential equations and causal relationships. These models emphasize interpretability and parameter estimation to describe system dynamics and predict outcomes under varied conditions. Unlike machine learning, mechanistic models provide insights into system mechanisms, enabling hypothesis testing and control strategy development.

Data Requirements: Machine Learning vs Mechanistic Models

Machine learning models demand large volumes of high-quality, diverse data to accurately identify patterns and make predictions, often relying on extensive labeled datasets for supervised learning. Mechanistic models, grounded in established scientific principles and equations, require less empirical data since they simulate systems based on theoretical frameworks and known interactions. Consequently, machine learning excels in data-rich environments, while mechanistic modeling is advantageous when data is scarce but domain knowledge is robust.

Predictive Accuracy and Interpretability

Machine learning excels in predictive accuracy by leveraging large datasets and complex algorithms to identify intricate patterns, often outperforming mechanistic modeling in data-rich environments. Mechanistic modeling offers superior interpretability by explicitly representing underlying processes through mathematical equations, enabling clearer insights into causal relationships. Balancing these approaches depends on the application: machine learning is preferred for high-accuracy forecasts, while mechanistic modeling is ideal where understanding system dynamics is crucial.

Scalability and Flexibility in Process Modeling

Machine learning models offer superior scalability in process modeling by efficiently handling large, complex datasets and adapting to new data without extensive reprogramming. Mechanistic modeling provides flexibility through its foundation in physical and chemical laws, enabling detailed interpretation and control of specific process variables. Combining machine learning's scalability with mechanistic models' interpretability enhances process optimization and predictive accuracy across diverse industrial applications.

Integration of Machine Learning with Mechanistic Models

Integrating machine learning with mechanistic models enhances predictive accuracy by combining data-driven insights with domain-specific knowledge, enabling more robust simulations of complex systems. Hybrid approaches leverage machine learning to estimate uncertain parameters or model residual processes within mechanistic frameworks, improving interpretability and generalization. This synergy supports advances in fields like systems biology, climate modeling, and engineering design by bridging theoretical understanding with empirical data.

Application Case Studies in Chemical Engineering

Machine learning models excel in predicting complex chemical reactions by learning from large datasets, as demonstrated in catalyst design and reaction yield optimization case studies. Mechanistic modeling provides insights into underlying reaction kinetics and transport phenomena, supporting process scale-up and control in chemical reactors. Combining both approaches enhances accuracy and interpretability in applications such as polymerization processes and biofuel production optimization.

Challenges and Limitations of Each Approach

Machine learning excels in pattern recognition and handling large datasets but struggles with interpretability and generalizing beyond training data, raising concerns about overfitting and data dependency. Mechanistic modeling offers clear causative insights and theoretical foundations but faces limitations in scalability and adaptability, often requiring simplifications that reduce accuracy in complex systems. Both approaches encounter challenges in balancing model complexity, computational demands, and the reliability of predictions in dynamic, real-world scenarios.

Future Perspectives: Hybrid Modeling and Industry Trends

Hybrid modeling, combining machine learning algorithms with mechanistic models, is gaining traction for its ability to improve predictive accuracy by integrating data-driven insights with domain knowledge. Industry trends indicate increased adoption in fields such as pharmaceuticals, energy, and manufacturing, where hybrid approaches enhance process optimization and decision-making. Future research focuses on developing scalable, interpretable frameworks that leverage the strengths of both methodologies to address complex, real-world problems efficiently.

Data-driven modeling

Machine learning excels in data-driven modeling by leveraging large datasets to identify complex patterns and make predictions without relying on predefined mechanistic assumptions.

First-principles modeling

First-principles modeling leverages fundamental physical laws to create mechanistic models, providing interpretable and accurate predictions compared to data-driven machine learning approaches.

Hybrid models

Hybrid models integrate machine learning algorithms with mechanistic modeling to enhance predictive accuracy and interpretability in complex systems.

Black-box models

Black-box machine learning models, unlike mechanistic modeling, predict outcomes without revealing underlying system processes, emphasizing data-driven accuracy over interpretability.

Physics-informed machine learning

Physics-informed machine learning integrates mechanistic modeling principles with data-driven algorithms to enhance predictive accuracy and interpretability in complex physical systems.

Parameter estimation

Machine learning excels in parameter estimation by leveraging large datasets for adaptive model refinement, whereas mechanistic modeling relies on predefined equations and assumptions for explicit parameter identification.

Model generalization

Machine learning models excel in model generalization by learning complex patterns from diverse data, whereas mechanistic models rely on predefined equations limiting their adaptability to unseen scenarios.

Process simulation

Machine learning enhances process simulation by leveraging data-driven models for predictive accuracy, while mechanistic modeling relies on fundamental physical laws to simulate process behavior.

Uncertainty quantification

Uncertainty quantification in machine learning leverages probabilistic models and Bayesian inference for flexible and data-driven uncertainty estimates, while mechanistic modeling relies on deterministic equations and sensitivity analysis to characterize uncertainty rooted in physical processes.

Transfer learning

Transfer learning enhances machine learning models by leveraging pre-trained knowledge for new tasks, offering greater adaptability and efficiency compared to rigid mechanistic modeling frameworks.

Machine learning vs mechanistic modeling Infographic

njnir.com

njnir.com