Selectivity and yield are critical metrics in chemical engineering that directly impact process efficiency and product quality. High selectivity minimizes undesired by-products, enhancing the purity and value of the target compound, while yield quantifies the amount of desired product obtained relative to theoretical maximums. Optimizing the balance between selectivity and yield ensures cost-effective reactions and sustainable production processes.

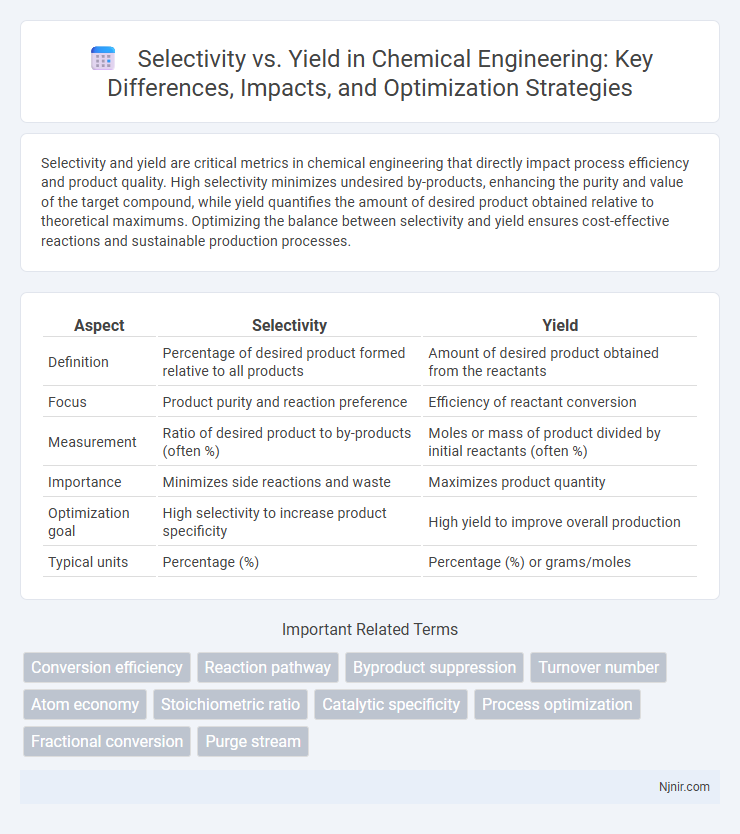

Table of Comparison

| Aspect | Selectivity | Yield |

|---|---|---|

| Definition | Percentage of desired product formed relative to all products | Amount of desired product obtained from the reactants |

| Focus | Product purity and reaction preference | Efficiency of reactant conversion |

| Measurement | Ratio of desired product to by-products (often %) | Moles or mass of product divided by initial reactants (often %) |

| Importance | Minimizes side reactions and waste | Maximizes product quantity |

| Optimization goal | High selectivity to increase product specificity | High yield to improve overall production |

| Typical units | Percentage (%) | Percentage (%) or grams/moles |

Introduction to Selectivity and Yield in Chemical Engineering

Selectivity in chemical engineering measures the preference of a chemical reaction to produce a desired product over undesired by-products, directly impacting process efficiency and economic viability. Yield quantifies the amount of target product obtained from given reactants, reflecting the conversion effectiveness within the reaction. Optimizing both selectivity and yield is critical for maximizing production efficiency and minimizing waste in industrial chemical processes.

Defining Selectivity: Key Concepts and Importance

Selectivity measures the preference of a chemical reaction to produce a desired product over undesired by-products, expressed as the ratio of the desired product formed to all products formed. It plays a crucial role in optimizing chemical processes by maximizing product purity and minimizing waste or side reactions. High selectivity enhances process efficiency, reduces separation costs, and supports sustainable production in industries such as pharmaceuticals and petrochemicals.

Understanding Yield: Calculation and Relevance

Yield represents the efficiency of a chemical reaction, calculated by dividing the actual amount of product obtained by the theoretical maximum amount, then multiplying by 100% to express it as a percentage. Understanding yield is crucial for assessing the productivity of a reaction, optimizing conditions, and minimizing waste in industrial processes. Accurate yield calculation helps chemists make informed decisions about process scalability and economic feasibility.

Relationship Between Selectivity and Yield

Selectivity and yield are critical parameters in chemical reactions that measure the efficiency and outcome of product formation. The relationship between selectivity and yield is often inversely proportional, where high selectivity towards a desired product can limit the total yield because fewer by-products are formed. Optimizing reaction conditions requires balancing selectivity and yield to maximize product purity while achieving acceptable conversion rates.

Factors Affecting Selectivity in Chemical Reactions

Factors affecting selectivity in chemical reactions include temperature, pressure, catalyst type, and reactant concentration, all of which influence the reaction pathway and product distribution. Catalyst surface properties and the presence of inhibitors or promoters significantly impact the reaction mechanism, enhancing selectivity toward desired products. Optimizing these parameters reduces side reactions and maximizes selectivity, improving overall yield and process efficiency.

Factors Influencing Yield Optimization

Factors influencing yield optimization in chemical reactions include reaction temperature, pressure, catalyst choice, and reactant concentration. Precise control over these parameters can enhance product formation while minimizing by-products, thus improving selectivity and overall yield. Advanced techniques like process intensification and in-situ monitoring further contribute to maximizing reaction efficiency and desired output.

Trade-offs: Balancing Selectivity and Yield in Process Design

Optimizing process design requires balancing selectivity and yield to maximize product quality while minimizing unwanted byproducts. High selectivity often reduces yield by favoring specific reactions, whereas maximizing yield can increase impurities, impacting purification costs and efficiency. Effective trade-off strategies involve catalyst design, reaction conditions, and separation technologies to achieve the desired balance for industrial applications.

Catalysts and Reaction Conditions: Impact on Selectivity and Yield

Catalysts play a crucial role in enhancing selectivity by favoring specific reaction pathways, thereby minimizing by-products and increasing overall yield. Reaction conditions such as temperature, pressure, and solvent choice directly influence catalyst activity and stability, affecting both selectivity and yield outcomes. Optimizing these parameters allows for tailored catalyst performance that maximizes product formation while reducing undesired side reactions.

Industrial Case Studies: Selectivity vs Yield in Practice

Industrial case studies reveal that optimizing selectivity directly impacts overall yield, as highly selective processes minimize by-products and enhance resource efficiency. For example, in pharmaceutical manufacturing, improving catalyst selectivity reduces purification steps, leading to increased production rates and lower costs. Chemical plants utilizing continuous flow reactors demonstrate higher yields through precise control of reaction parameters that favor desired product formation over undesired side reactions.

Strategies for Enhancing Selectivity and Yield in Chemical Processes

Optimizing selectivity and yield in chemical processes involves precise control of reaction conditions, such as temperature, pressure, and catalyst choice, to favor desired products while minimizing by-products. Implementing advanced catalysts with high specificity and utilizing reaction engineering techniques like flow reactors enhance product purity and conversion rates. Process intensification strategies, including continuous monitoring and adaptive control systems, further improve overall efficiency by balancing selectivity and yield in complex chemical reactions.

Conversion efficiency

High selectivity improves conversion efficiency by minimizing undesired byproducts and maximizing yield of the target product.

Reaction pathway

Selectivity defines the preference of a reaction pathway toward a desired product, while yield measures the efficiency of converting reactants into that product within that pathway.

Byproduct suppression

High selectivity enhances yield by effectively suppressing byproduct formation, optimizing reaction efficiency and product purity.

Turnover number

Turnover number critically influences the balance between selectivity and yield by determining the efficiency and rate at which a catalyst converts reactants into desired products.

Atom economy

Maximizing atom economy enhances yield by increasing selectivity through efficient utilization of all reactant atoms in a chemical reaction.

Stoichiometric ratio

Optimizing the stoichiometric ratio is crucial for maximizing selectivity while maintaining high yield in chemical reactions.

Catalytic specificity

Catalytic specificity enhances selectivity and yield by enabling catalysts to preferentially convert targeted substrates into desired products with minimal byproducts.

Process optimization

Optimizing process parameters enhances selectivity to target products while maximizing overall yield, driving efficient resource utilization and cost-effectiveness in chemical manufacturing.

Fractional conversion

Fractional conversion directly impacts the balance between selectivity and yield, with higher fractional conversion often decreasing selectivity but increasing overall product yield.

Purge stream

Optimizing purge stream conditions enhances selectivity by removing impurities while maintaining high yield in chemical processes.

Selectivity vs Yield Infographic

njnir.com

njnir.com