3D printing in chemical engineering enables the rapid prototyping and fabrication of complex reactor geometries that traditional manufacturing methods struggle to achieve. This additive process reduces material waste and allows for customization at a lower cost, enhancing experimental flexibility and scaling options. Traditional manufacturing, while efficient for large-scale production, often involves longer lead times and higher material usage, limiting innovation in device design.

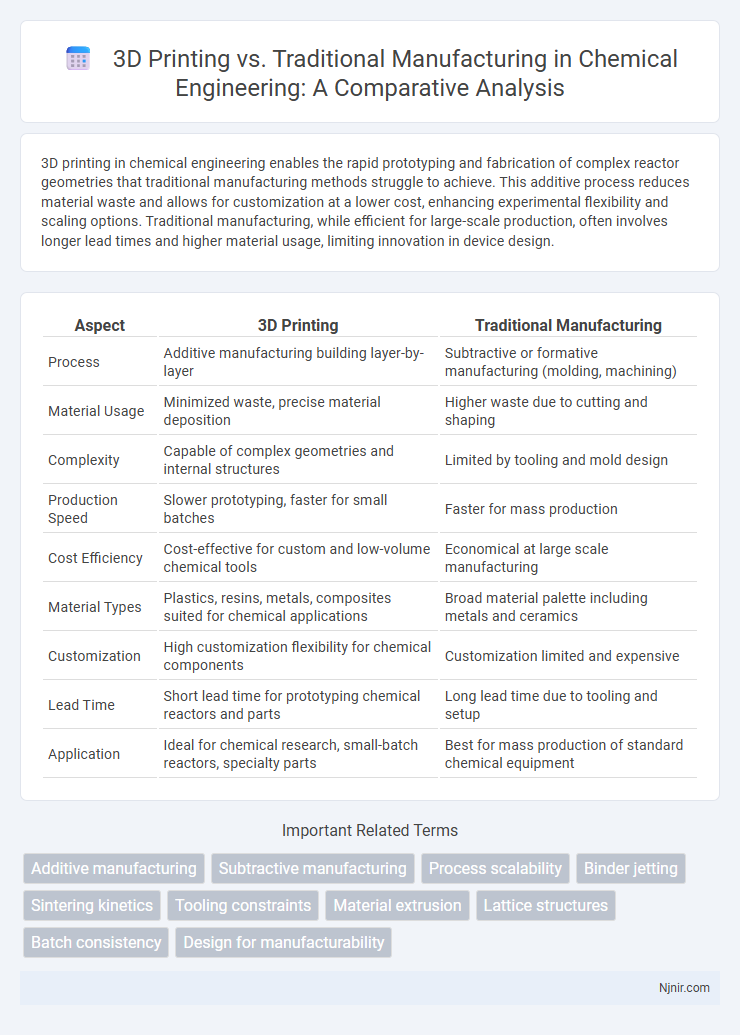

Table of Comparison

| Aspect | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Process | Additive manufacturing building layer-by-layer | Subtractive or formative manufacturing (molding, machining) |

| Material Usage | Minimized waste, precise material deposition | Higher waste due to cutting and shaping |

| Complexity | Capable of complex geometries and internal structures | Limited by tooling and mold design |

| Production Speed | Slower prototyping, faster for small batches | Faster for mass production |

| Cost Efficiency | Cost-effective for custom and low-volume chemical tools | Economical at large scale manufacturing |

| Material Types | Plastics, resins, metals, composites suited for chemical applications | Broad material palette including metals and ceramics |

| Customization | High customization flexibility for chemical components | Customization limited and expensive |

| Lead Time | Short lead time for prototyping chemical reactors and parts | Long lead time due to tooling and setup |

| Application | Ideal for chemical research, small-batch reactors, specialty parts | Best for mass production of standard chemical equipment |

Introduction to 3D Printing and Traditional Manufacturing in Chemical Engineering

3D printing, or additive manufacturing, enables layer-by-layer material deposition to create complex chemical engineering components with precision and reduced waste, contrasting with traditional manufacturing methods that rely on subtractive processes like machining and molding. Traditional manufacturing in chemical engineering often involves casting, forging, or extrusion to produce large volumes of uniform parts, emphasizing scalability and material strength. The integration of 3D printing in chemical engineering facilitates rapid prototyping, customization, and production of intricate reactor designs that are challenging or impossible to achieve through conventional methods.

Material Compatibility and Selection

3D printing offers a diverse range of material compatibility, including thermoplastics, resins, metals, and composites, enabling intricate designs and rapid prototyping. Traditional manufacturing supports a broader spectrum of materials such as steel, aluminum, and ceramics, with established processes for high-strength and large-scale production. Material selection in 3D printing emphasizes customization and lightweight applications, while traditional manufacturing prioritizes durability and material performance in mass production.

Design Flexibility and Customization

3D printing offers unparalleled design flexibility by enabling the creation of complex geometries and intricate details that are difficult or impossible to achieve with traditional manufacturing methods such as injection molding or CNC machining. Customization is seamlessly integrated into the process, allowing for rapid prototyping and individualized production without significant cost increases or tooling changes. Traditional manufacturing excels in mass production efficiency but lacks the adaptability to easily modify designs or produce low-volume, customized parts.

Process Efficiency and Lead Time

3D printing significantly enhances process efficiency by enabling on-demand production with minimal setup, reducing material waste through additive layer construction. Traditional manufacturing often involves multiple machining steps and tooling preparation, leading to longer lead times and higher upfront costs. The rapid prototyping capability of 3D printing accelerates product development cycles, cutting lead times from weeks to days compared to conventional methods.

Cost Considerations and Economic Viability

3D printing reduces upfront tooling costs and enables economical production of low-volume or custom parts, contrasting with traditional manufacturing's high initial investment for molds and setups. While per-unit costs in additive manufacturing remain higher for large-scale production, its flexibility minimizes material waste and inventory expenses, enhancing overall economic viability for prototyping and small batches. Traditional manufacturing excels in cost efficiency at mass production scale due to economies of scale, making it more suitable for high-volume, standardized products.

Environmental Impact and Sustainability

3D printing significantly reduces material waste compared to traditional manufacturing by using additive processes that build objects layer by layer, minimizing excess raw materials. It enables localized production, which decreases transportation emissions and lowers the overall carbon footprint associated with supply chains. Moreover, 3D printing allows for the use of sustainable and recyclable materials, contributing to enhanced environmental sustainability in manufacturing practices.

Quality Control and Precision

3D printing offers exceptional precision by building objects layer-by-layer, enabling complex geometries and consistent dimensional accuracy unattainable in many traditional manufacturing processes. Quality control in 3D printing heavily relies on real-time monitoring and digital scans to detect defects early, contrasting with traditional methods that often depend on post-production inspections and manual measurements. While traditional manufacturing excels in repeatability for large production runs, 3D printing provides superior customization and precise control over intricate part features, enhancing overall quality assurance.

Scalability and Mass Production

3D printing offers rapid prototyping and customization but faces limitations in scalability and mass production due to slower build speeds and higher per-unit costs compared to traditional manufacturing. Traditional manufacturing excels in producing large volumes efficiently with established processes like injection molding and CNC machining, reducing cost per unit as scale increases. For industries requiring high-volume output, traditional methods remain more cost-effective and time-efficient, while 3D printing serves best for small batch production and complex, bespoke designs.

Applications in Chemical Engineering Industries

3D printing revolutionizes chemical engineering by enabling rapid prototyping and custom fabrication of complex reactor components and microfluidic devices that traditional manufacturing struggles to produce. This technology improves catalyst design, allowing precise control over pore structures and surface areas, enhancing reaction efficiency and scalability. In contrast, conventional manufacturing relies on batch production and machining processes, limiting flexibility and increasing lead times for specialized chemical processing equipment.

Future Trends and Innovations

Future trends in 3D printing emphasize advanced materials such as bioinks, metal alloys, and composites that enable more durable, lightweight, and functional products across industries like aerospace and healthcare. Innovations in multi-material printing and AI-driven process optimization are accelerating production speed and precision, reducing reliance on traditional manufacturing supply chains. The convergence of 3D printing with IoT and Industry 4.0 technologies is driving smart factories where rapid prototyping and customized mass production coexist, reshaping the manufacturing landscape.

Additive manufacturing

Additive manufacturing in 3D printing enables rapid prototyping, complex geometries, and material efficiency that traditional subtractive manufacturing methods cannot easily achieve.

Subtractive manufacturing

Subtractive manufacturing removes material using processes like CNC machining, offering precise, high-strength parts but often generates more waste and requires longer production times compared to 3D printing.

Process scalability

3D printing offers rapid process scalability with minimal setup changes, enabling efficient customization and small production runs compared to traditional manufacturing's slower scalability reliant on extensive tooling and molds.

Binder jetting

Binder jetting enables faster, cost-effective 3D printing of complex metal parts with minimal material waste compared to traditional subtractive manufacturing techniques.

Sintering kinetics

Sintering kinetics in 3D printing enable faster, more precise material fusion at lower temperatures compared to traditional manufacturing, enhancing microstructural control and reducing production time.

Tooling constraints

3D printing overcomes traditional manufacturing tooling constraints by enabling rapid prototyping and complex geometries without the need for expensive molds or dies.

Material extrusion

Material extrusion in 3D printing enables precise, cost-effective production of complex geometries compared to traditional manufacturing methods that often involve subtractive processes and higher material waste.

Lattice structures

Lattice structures in 3D printing offer superior design flexibility and weight reduction compared to traditional manufacturing methods, enabling optimized mechanical performance and material efficiency.

Batch consistency

3D printing enables rapid adaptation with moderate batch consistency, while traditional manufacturing ensures high batch consistency through standardized processes and quality controls.

Design for manufacturability

Design for manufacturability in 3D printing enables complex geometries and rapid prototyping unattainable by traditional manufacturing methods constrained by tooling and machining limitations.

3D printing vs traditional manufacturing Infographic

njnir.com

njnir.com