Amine scrubbing effectively removes acidic gases like CO2 and H2S from gas streams through chemical absorption, offering high selectivity and capacity in treating low to moderate gas concentrations. Pressure swing adsorption (PSA) separates gases based on their adsorption properties on solid adsorbents, enabling rapid cyclic operation and energy-efficient purification, especially for higher gas concentrations. While amine scrubbing excels in handling large volumes with continuous operation, PSA provides flexibility and lower solvent handling, making each technique suitable for different industrial gas separation needs.

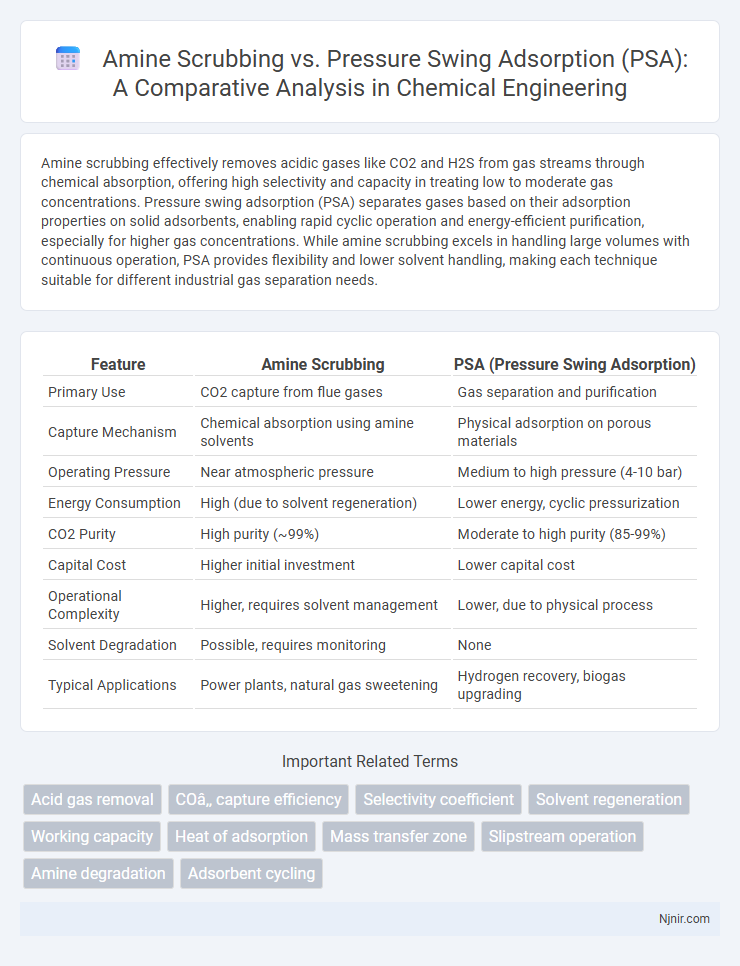

Table of Comparison

| Feature | Amine Scrubbing | PSA (Pressure Swing Adsorption) |

|---|---|---|

| Primary Use | CO2 capture from flue gases | Gas separation and purification |

| Capture Mechanism | Chemical absorption using amine solvents | Physical adsorption on porous materials |

| Operating Pressure | Near atmospheric pressure | Medium to high pressure (4-10 bar) |

| Energy Consumption | High (due to solvent regeneration) | Lower energy, cyclic pressurization |

| CO2 Purity | High purity (~99%) | Moderate to high purity (85-99%) |

| Capital Cost | Higher initial investment | Lower capital cost |

| Operational Complexity | Higher, requires solvent management | Lower, due to physical process |

| Solvent Degradation | Possible, requires monitoring | None |

| Typical Applications | Power plants, natural gas sweetening | Hydrogen recovery, biogas upgrading |

Overview of Gas Separation Technologies

Amine scrubbing utilizes chemical absorption to selectively remove CO2 from gas streams by reacting with amine solutions, offering high CO2 capture efficiency ideal for large-scale applications. Pressure Swing Adsorption (PSA) operates by adsorbing impurities onto solid adsorbents under high pressure and desorbing them at low pressure, enabling efficient separation of gases like hydrogen or nitrogen with rapid cycle times. Both technologies are essential in gas separation, with amine scrubbing preferred for high CO2 gas volumes and PSA suited for gas purification and recovery in various industrial processes.

Principles of Amine Scrubbing

Amine scrubbing relies on chemical absorption where aqueous amine solutions selectively react with acidic gases such as CO2 and H2S, forming soluble compounds that can be regenerated by heating. This process operates under continuous flow conditions, allowing the amine solution to absorb contaminants from gas streams and release purified gases upon thermal regeneration. The efficiency of amine scrubbing depends on factors like amine type, concentration, temperature, and pressure, making it highly effective for treating high CO2 concentrations in natural gas and industrial emissions.

Fundamentals of Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption (PSA) separates gases by exploiting differences in adsorption characteristics on solid adsorbents under varying pressure conditions. During PSA, feed gas is pressurized to cause selective adsorption of targeted components onto the adsorbent material, and depressurized to desorb and recover the purified product gas. This cyclic process relies on materials like zeolites or activated carbon, with adsorption capacity influenced by pressure, temperature, and adsorption selectivity, providing efficient and scalable gas separation without the need for chemical solvents used in amine scrubbing.

Key Applications in Chemical Engineering

Amine scrubbing is predominantly used for CO2 capture in natural gas processing and post-combustion carbon capture due to its high selectivity and efficiency in removing acid gases from gas streams. Pressure Swing Adsorption (PSA) is commonly applied for hydrogen purification, nitrogen generation, and oxygen production in chemical plants because of its rapid cyclic operation and ability to separate gases based on molecular adsorption properties. Both technologies are integral in gas treatment processes, with amine scrubbing favored for solvent-based absorption and PSA preferred for pressure-driven gas separation in chemical engineering applications.

Comparative Efficiency: Amine Scrubbing vs PSA

Amine scrubbing demonstrates high efficiency in removing carbon dioxide from gas streams, achieving CO2 capture rates exceeding 90% under optimal conditions. PSA (Pressure Swing Adsorption) offers rapid gas separation with lower energy consumption but typically achieves CO2 purities around 85-95%, which may be less efficient for high-purity requirements. The comparative efficiency hinges on feed gas composition and scale, with amine scrubbing favored for high CO2 concentrations and continuous large-scale operations, while PSA suits variable gas streams and modular applications.

Operational Parameters and Energy Requirements

Amine scrubbing operates at lower pressures typically between 1 to 5 bar and requires significant thermal energy for solvent regeneration, often consuming 3.5 to 4 GJ per tonne of CO2 captured, driven by the need to heat the amine solution. In contrast, Pressure Swing Adsorption (PSA) runs at higher pressures, usually 4 to 10 bar, relying primarily on pressure swings for adsorption and desorption cycles, resulting in lower thermal but higher electrical energy consumption mainly due to compressors and vacuum pumps. Energy efficiency in PSA depends on cycle time and adsorbent material, while amine scrubbing's energy needs are dominated by regeneration heat duty and solvent degradation rates.

Environmental Impact and Emissions

Amine scrubbing captures CO2 through chemical absorption, significantly reducing greenhouse gas emissions but generating secondary waste streams and potential solvent degradation byproducts that require careful management. In contrast, PSA relies on physical adsorption to separate gases, minimizing chemical waste but often consuming more energy, which can lead to indirect emissions depending on the energy source. The overall environmental impact of each technology depends on the specific application, operational efficiency, and waste handling practices.

Economic Considerations and Cost Analysis

Amine scrubbing generally involves higher initial capital expenditure and operational costs due to solvent management and energy-intensive regeneration processes, while PSA systems typically require lower energy input and have reduced chemical expenses, making them more cost-efficient for small to medium-scale CO2 capture. Economic considerations also account for amine scrubbers' higher solvent degradation and replacement costs, in contrast to PSA's relatively minimal consumable use and lower maintenance demands. Cost analysis shows that amine scrubbing is more favorable in scenarios with high CO2 concentration streams, whereas PSA offers greater economic benefits in low CO2 concentration applications with fluctuating gas compositions.

Scalability and Industrial Adoption

Amine scrubbing demonstrates high scalability for large-scale industrial applications due to its mature technology and proven efficiency in capturing CO2 from flue gases. Pressure Swing Adsorption (PSA) offers modular scalability with quicker cycle times, making it suitable for variable capacity plants and smaller-scale operations. Industrial adoption favors amine scrubbing in established sectors like power generation and natural gas processing, while PSA gains traction in industries requiring rapid purification and flexibility, such as hydrogen production and biogas upgrading.

Future Trends in Gas Separation Technologies

Future trends in gas separation technologies emphasize enhanced energy efficiency and lower operational costs, with amine scrubbing evolving through advanced amines and hybrid systems to reduce solvent degradation and emissions. PSA is progressing with improved adsorbent materials like metal-organic frameworks (MOFs) and tailored pore structures to increase selectivity and cycle times. Integration of machine learning for process optimization and the development of modular, scalable units highlight the future direction of both technologies in carbon capture and hydrogen purification applications.

Acid gas removal

Amine scrubbing achieves over 99% acid gas removal efficiency by chemically absorbing CO2 and H2S, while PSA selectively adsorbs acid gases using pressure variations but typically attains lower purity and recovery rates.

CO₂ capture efficiency

Amine scrubbing achieves CO2 capture efficiencies of over 90% in post-combustion gas streams, whereas Pressure Swing Adsorption (PSA) typically offers lower capture efficiencies around 70-85%, making amine scrubbing more effective for high-purity CO2 separation.

Selectivity coefficient

Amine scrubbing exhibits a higher selectivity coefficient for CO2 over N2 compared to PSA, enabling more efficient and selective carbon capture from gas streams.

Solvent regeneration

Amine scrubbing uses thermal regeneration to recover solvents through heat application, whereas PSA relies on pressure changes to selectively adsorb and release impurities for solvent recovery.

Working capacity

Amine scrubbing offers a higher working capacity for CO2 capture compared to Pressure Swing Adsorption (PSA), enabling more efficient absorption and regeneration cycles in gas separation processes.

Heat of adsorption

Amine scrubbing involves a higher heat of adsorption due to chemical interactions with CO2, whereas pressure swing adsorption (PSA) relies on physical adsorption with a significantly lower heat of adsorption, affecting their overall energy efficiency in gas separation processes.

Mass transfer zone

Amine scrubbing features a longer mass transfer zone due to liquid-phase absorption, whereas PSA utilizes a shorter mass transfer zone within gas-phase adsorption beds for faster contaminant separation.

Slipstream operation

Amine scrubbing provides higher CO2 capture efficiency in slipstream operations compared to Pressure Swing Adsorption (PSA), which offers faster regeneration but lower purity in small-scale integration.

Amine degradation

Amine scrubbing experiences significant amine degradation due to oxidative and thermal reactions, resulting in higher operational costs compared to the less chemically intensive PSA process for gas separation.

Adsorbent cycling

Amine scrubbing relies on chemical absorption with liquid solvents for CO2 capture, while PSA uses adsorbent cycling with porous solid materials to separate gases based on pressure-induced adsorption and desorption phases.

Amine scrubbing vs PSA (Pressure swing adsorption) Infographic

njnir.com

njnir.com