Slurry reactors offer enhanced heat transfer and improved mass transfer due to the fluidized solid particles suspended in the liquid phase, making them ideal for reactions involving solids and liquids with high solid loadings. In contrast, packed bed reactors provide a fixed catalyst bed that enables stable flow patterns and simpler design but may suffer from channeling and pressure drop issues, particularly with viscous fluids. Choosing between these reactor types depends on reaction kinetics, catalyst properties, and operational parameters such as temperature control and scale-up requirements.

Table of Comparison

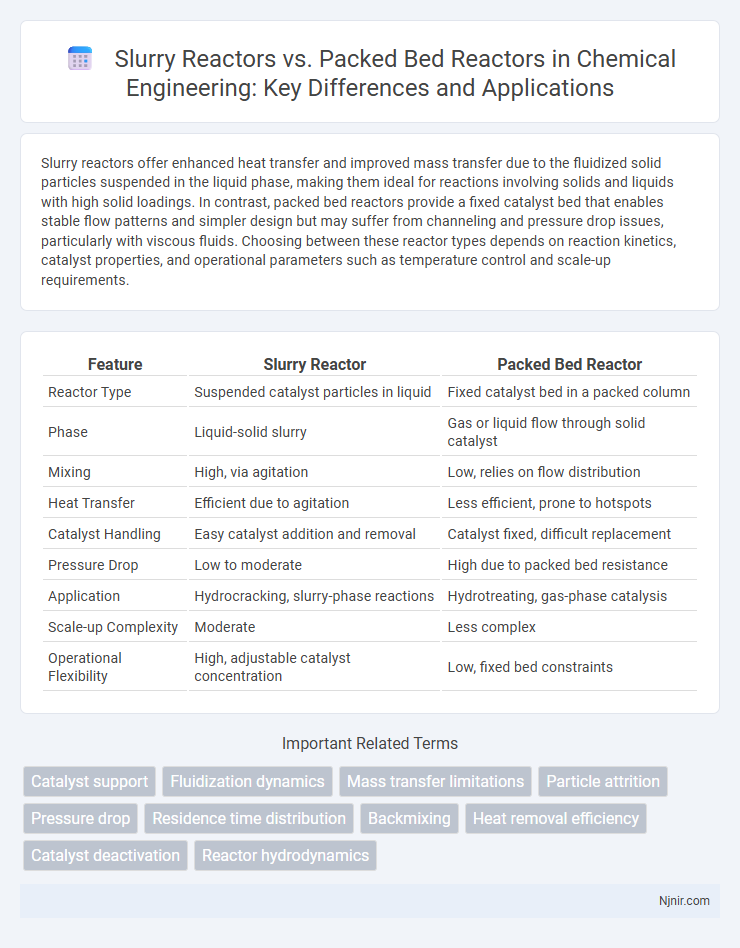

| Feature | Slurry Reactor | Packed Bed Reactor |

|---|---|---|

| Reactor Type | Suspended catalyst particles in liquid | Fixed catalyst bed in a packed column |

| Phase | Liquid-solid slurry | Gas or liquid flow through solid catalyst |

| Mixing | High, via agitation | Low, relies on flow distribution |

| Heat Transfer | Efficient due to agitation | Less efficient, prone to hotspots |

| Catalyst Handling | Easy catalyst addition and removal | Catalyst fixed, difficult replacement |

| Pressure Drop | Low to moderate | High due to packed bed resistance |

| Application | Hydrocracking, slurry-phase reactions | Hydrotreating, gas-phase catalysis |

| Scale-up Complexity | Moderate | Less complex |

| Operational Flexibility | High, adjustable catalyst concentration | Low, fixed bed constraints |

Introduction to Slurry and Packed Bed Reactors

Slurry reactors operate by suspending solid catalyst particles within a liquid reactant phase, enabling effective heat transfer and high mass transfer rates, commonly used in Fischer-Tropsch synthesis and hydrotreating processes. Packed bed reactors consist of a fixed bed of catalyst particles through which gas or liquid reactants flow, offering simplicity in design and operation with efficient catalytic contact, widely applied in catalytic reforming and isomerization. Both reactor types optimize catalytic reactions but differ significantly in mixing, catalyst handling, and heat management.

Fundamental Design Differences

Slurry reactors feature a suspension of solid catalyst particles in a liquid phase, enabling excellent heat transfer and high mass transfer rates due to intimate contact between phases. Packed bed reactors consist of a fixed bed of catalyst pellets through which reactant fluids flow, ensuring well-defined flow paths but potentially suffering from pressure drop and diffusion limitations. The fundamental design difference lies in the catalyst handling and phase interaction: slurry reactors allow dynamic catalyst movement with suspension, whereas packed beds provide a stationary catalyst arrangement for continuous flow operations.

Catalyst Utilization and Distribution

Slurry reactors offer superior catalyst utilization due to enhanced mass and heat transfer, allowing uniform catalyst distribution within the liquid phase. Packed bed reactors exhibit fixed catalyst placement, which can lead to channeling and uneven reactant flow, potentially reducing catalyst efficiency. The dynamic mixing in slurry reactors promotes better catalyst contact and activity compared to the static structure of packed beds.

Mass and Heat Transfer Mechanisms

Slurry reactors exhibit enhanced heat and mass transfer due to the intimate contact between solid catalyst particles and the liquid phase, promoting efficient mixing and minimizing external diffusion limitations. Packed bed reactors rely on fluid flow through a fixed catalyst bed, where mass transfer is governed by diffusion within catalyst pores and convective transport in the interstitial voids, often leading to higher temperature gradients. The choice between slurry and packed bed reactors significantly impacts reaction kinetics, with slurry reactors offering superior thermal management and uniform concentration profiles, while packed beds may experience channeling and hotspot formation.

Operating Conditions and Flexibility

Slurry reactors operate at moderate to high pressures and temperatures, allowing efficient mass and heat transfer due to catalyst particles suspended in the liquid phase, offering superior flexibility for handling feedstock variations and catalyst regeneration. Packed bed reactors function under a wider range of pressures but are typically optimized for lower temperature gradients, with fixed catalyst beds providing less operational flexibility and increased risk of channeling or hot spots under variable conditions. The slurry reactor's adaptability to changing reaction rates and ease of catalyst replacement enhance process control compared to the more rigid operation of packed bed reactors.

Scale-Up Challenges and Considerations

Scaling up slurry reactors involves managing solid-liquid suspension homogeneity and heat transfer efficiency to prevent catalyst agglomeration and ensure uniform reaction rates. Packed bed reactors pose challenges in maintaining consistent flow distribution and minimizing channeling effects, which can lead to uneven temperature profiles and reduced catalyst utilization. Both reactor types require careful consideration of hydrodynamics, mass transfer limitations, and pressure drop to achieve optimal performance at industrial scales.

Applications in Chemical Engineering Industries

Slurry reactors excel in processes requiring enhanced heat transfer and solid-liquid mixing, making them ideal for Fischer-Tropsch synthesis and hydrocracking in petrochemical industries. Packed bed reactors are preferred for catalytic gas-phase reactions such as ammonia synthesis and methanol production due to their high catalyst surface area and efficient gas flow distribution. Both reactor types optimize reaction rates and selectivity but are chosen based on phase interactions and operational scale in chemical engineering applications.

Advantages and Disadvantages Comparison

Slurry reactors offer enhanced heat transfer and excellent mixing, making them ideal for reactions involving solids and liquids, but they face challenges in solid separation and catalyst recovery. Packed bed reactors provide high catalyst efficiency and straightforward operation with minimal catalyst loss, though they may suffer from channeling and pressure drop issues limiting mass transfer. Selecting between slurry and packed bed reactors depends on process requirements such as catalyst type, reaction kinetics, and scale of operation.

Performance Efficiency and Productivity

Slurry reactors achieve higher mass transfer rates and better heat management due to the intimate contact between solid catalysts and liquid reactants, resulting in enhanced reaction rates and superior performance efficiency. Packed bed reactors, while offering simpler operation and lower pressure drops, often face limitations in catalyst utilization and mass transfer, which can reduce overall productivity. The choice between slurry and packed bed reactors depends on the specific reaction kinetics and process scale, with slurry reactors generally favored for processes requiring high conversion and selectivity.

Future Trends and Reactor Selection Criteria

Future trends in slurry reactors emphasize enhanced mixing efficiency and scalable catalyst recovery, addressing mass transfer limitations for fine particulate catalysts. Packed bed reactors continue evolving with improved catalyst support materials to minimize pressure drop and extend catalyst life under high-temperature conditions. Reactor selection criteria prioritize reaction kinetics, catalyst type, heat management, and operational scalability to optimize performance and economic viability in industrial applications.

Catalyst support

Slurry reactors use suspended catalyst particles providing high heat transfer and mass transfer rates, whereas packed bed reactors contain fixed catalyst supports offering enhanced mechanical strength and ease of catalyst separation.

Fluidization dynamics

Slurry reactors utilize fluidization dynamics to suspend catalyst particles in a liquid phase, enhancing mass transfer rates and heat distribution compared to the fixed catalyst arrangement in packed bed reactors, which experience limited fluidization and increased pressure drop.

Mass transfer limitations

Slurry reactors exhibit reduced mass transfer limitations due to enhanced mixing and particle suspension, whereas packed bed reactors often face increased mass transfer resistance caused by stagnant zones and limited fluid dynamics.

Particle attrition

Slurry reactors exhibit lower particle attrition compared to packed bed reactors due to enhanced particle suspension and reduced mechanical stress.

Pressure drop

Slurry reactors exhibit lower pressure drop due to their fluidized catalyst particles, whereas packed bed reactors face higher pressure drop caused by fixed catalyst beds restricting fluid flow.

Residence time distribution

Slurry reactors exhibit broader residence time distributions due to particle and liquid phase mixing, while packed bed reactors typically show narrower residence time distributions because of their fixed, uniform bed structure.

Backmixing

Slurry reactors exhibit significant backmixing due to their dispersed solid-liquid phase, while packed bed reactors promote plug flow with minimal backmixing, enhancing concentration gradients and reaction control.

Heat removal efficiency

Slurry reactors offer superior heat removal efficiency compared to packed bed reactors due to enhanced mixing and higher heat transfer rates from catalyst particles suspended in the fluid phase.

Catalyst deactivation

Slurry reactors minimize catalyst deactivation through enhanced suspension and heat transfer, while packed bed reactors often experience faster catalyst deactivation due to channeling and hot spots.

Reactor hydrodynamics

Slurry reactors exhibit enhanced mixing and improved mass transfer due to suspended catalyst particles, whereas packed bed reactors rely on fixed catalyst beds, resulting in distinct flow patterns and pressure drop characteristics impacting overall reactor hydrodynamics.

Slurry reactor vs Packed bed reactor Infographic

njnir.com

njnir.com