Microreactors offer enhanced heat and mass transfer rates compared to traditional reactors, leading to improved reaction control and higher product yields. Their small channel dimensions enable precise temperature regulation and rapid mixing, reducing side reactions and improving safety by minimizing hazardous volumes. Traditional reactors, while scalable for large production volumes, often suffer from inefficiencies related to heat dissipation and slower mass transfer, impacting overall process intensification.

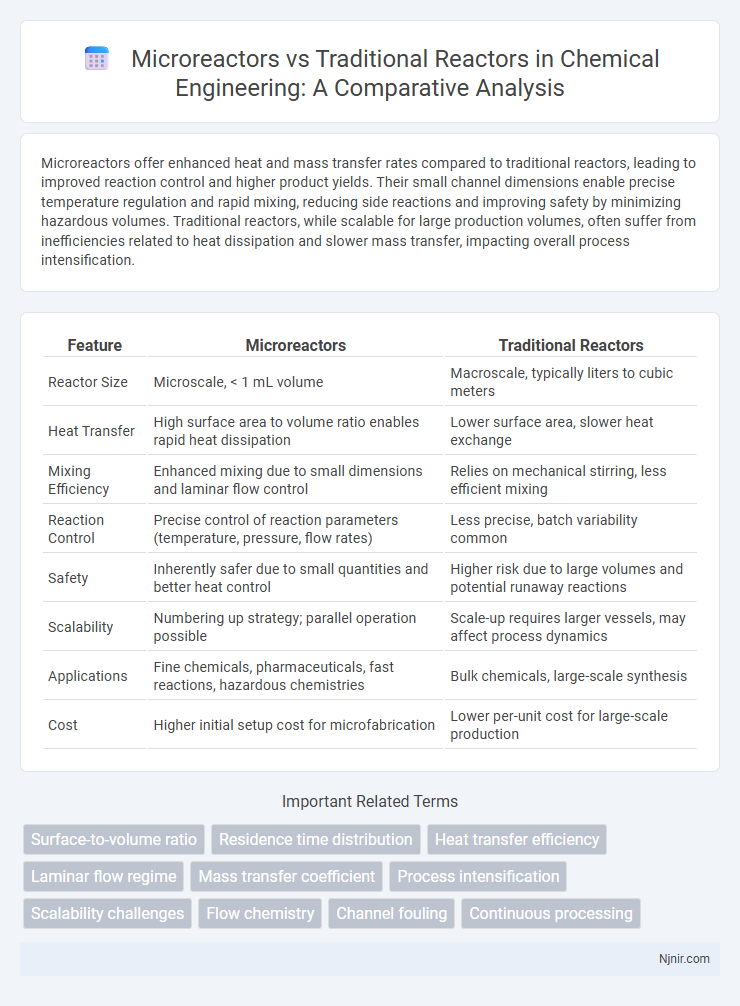

Table of Comparison

| Feature | Microreactors | Traditional Reactors |

|---|---|---|

| Reactor Size | Microscale, < 1 mL volume | Macroscale, typically liters to cubic meters |

| Heat Transfer | High surface area to volume ratio enables rapid heat dissipation | Lower surface area, slower heat exchange |

| Mixing Efficiency | Enhanced mixing due to small dimensions and laminar flow control | Relies on mechanical stirring, less efficient mixing |

| Reaction Control | Precise control of reaction parameters (temperature, pressure, flow rates) | Less precise, batch variability common |

| Safety | Inherently safer due to small quantities and better heat control | Higher risk due to large volumes and potential runaway reactions |

| Scalability | Numbering up strategy; parallel operation possible | Scale-up requires larger vessels, may affect process dynamics |

| Applications | Fine chemicals, pharmaceuticals, fast reactions, hazardous chemistries | Bulk chemicals, large-scale synthesis |

| Cost | Higher initial setup cost for microfabrication | Lower per-unit cost for large-scale production |

Introduction to Microreactors and Traditional Reactors

Microreactors feature compact designs with enhanced heat and mass transfer capabilities, enabling precise control over reaction conditions and improved safety profiles compared to traditional reactors. Traditional reactors, such as batch and continuous stirred-tank reactors, have larger volumes and rely on conventional mixing and heat exchange methods, often resulting in slower reaction rates and scalability challenges. Microreactors provide rapid prototyping and process intensification advantages, making them ideal for pharmaceutical synthesis and fine chemical production.

Design Principles: Microreactors vs Traditional Reactors

Microreactors leverage modular, compact designs that enable enhanced heat and mass transfer through microchannel structures, contrasting traditional reactors that rely on larger, bulkier vessels with slower thermal gradients. The high surface-to-volume ratio in microreactors facilitates precise control over reaction conditions and improved safety profiles by minimizing hazardous material inventory at any time. Traditional reactors often require extensive scaling strategies and robust mechanical components, while microreactors emphasize process intensification and continuous flow operations for higher efficiency and scalability.

Reaction Efficiency and Yield Comparison

Microreactors offer significantly higher reaction efficiency compared to traditional reactors due to enhanced heat and mass transfer achieved through their small channel dimensions, which allow for precise temperature control and rapid mixing. This improved reaction environment leads to higher yield percentages, often exceeding those obtained in classic batch or large-scale flow reactors by minimizing side reactions and degradation. Studies demonstrate that microreactors can increase yield by up to 30% in processes such as catalytic hydrogenations and complex organic syntheses, highlighting their superiority in scalable, efficient chemical manufacturing.

Heat and Mass Transfer Characteristics

Microreactors exhibit superior heat and mass transfer characteristics compared to traditional reactors due to their high surface-to-volume ratio, enabling rapid heat dissipation and enhanced mixing efficiency. The reduced diffusion distances in microchannels facilitate faster reactant transport and improved temperature control, minimizing hot spots and leading to more consistent reaction conditions. These advantages result in higher reaction selectivity and increased safety margins, making microreactors particularly suitable for exothermic or highly sensitive chemical processes.

Safety Considerations in Reactor Selection

Microreactors offer enhanced safety features compared to traditional reactors due to their smaller size, inherent passive cooling systems, and lower operational pressures, which reduce the risk of catastrophic failures. Traditional reactors, although extensively tested and regulated, require complex safety systems to manage higher power outputs and potential radiation release. Selecting reactors based on safety prioritizes microreactors for remote or emergency applications where compact design and simplified safety reduce human error and environmental impact.

Scale-Up and Flexibility in Chemical Manufacturing

Microreactors offer superior scale-up capabilities in chemical manufacturing by enabling precise control over reaction conditions and seamless parallelization, allowing for rapid production increases without extensive reengineering. Traditional reactors often face challenges in scaling due to their large size, heat transfer limitations, and slower response times, which can lead to inefficiencies and safety concerns. The inherent flexibility of microreactors supports diverse chemical processes and fast adaptation to market demands, contrasting with the rigidity of traditional reactors that require significant downtime and capital investment for process changes.

Cost Analysis: Capital and Operational Expenditure

Microreactors typically exhibit lower capital expenditure due to modular designs and reduced construction times compared to traditional reactors, which require extensive infrastructure and longer build periods. Operational expenditure in microreactors is often minimized by enhanced safety features, lower fuel consumption, and simplified maintenance protocols, contrasting with the higher costs associated with large-scale reactor operations and waste management. These cost dynamics position microreactors as economically viable alternatives for decentralized energy production and specialized industrial applications.

Sustainability and Green Chemistry Implications

Microreactors enhance sustainability by minimizing waste and energy consumption through precise control over reaction conditions, aligning with green chemistry principles. Their compact design enables efficient heat and mass transfer, reducing the need for hazardous solvents and lowering the environmental footprint compared to traditional batch reactors. This shift supports the development of cleaner chemical processes with improved safety, scalability, and reduced resource usage.

Industrial Applications and Case Studies

Microreactors offer enhanced heat and mass transfer rates, enabling precise control over reaction conditions and significantly improving product yields in industrial chemical processes. Case studies in pharmaceutical manufacturing demonstrate microreactors' ability to conduct continuous-flow reactions with reduced energy consumption and minimized waste compared to traditional batch reactors. Traditional reactors remain favored for large-scale, high-volume production due to their established infrastructure but often face limitations in scalability and process safety.

Future Trends in Reactor Technology

Microreactors offer enhanced flexibility, improved safety features, and rapid deployment capabilities compared to traditional large-scale reactors, making them ideal for decentralized power generation and remote applications. Advances in modular design, solid-state materials, and AI-driven control systems are driving the future trends in reactor technology toward smaller, more efficient, and highly autonomous operations. Integration with renewable energy sources and the development of novel fuel cycles are anticipated to further boost the sustainability and economic feasibility of microreactors in the evolving energy landscape.

Surface-to-volume ratio

Microreactors exhibit significantly higher surface-to-volume ratios compared to traditional reactors, enhancing heat transfer efficiency and reaction control.

Residence time distribution

Microreactors exhibit narrower residence time distributions than traditional reactors, enhancing reaction control and product uniformity.

Heat transfer efficiency

Microreactors achieve significantly higher heat transfer efficiency than traditional reactors due to their increased surface-area-to-volume ratio and enhanced fluid dynamics.

Laminar flow regime

Microreactors enable precise control of the laminar flow regime with enhanced surface-to-volume ratios, improving reaction efficiency and heat transfer compared to traditional reactors.

Mass transfer coefficient

Microreactors exhibit significantly higher mass transfer coefficients than traditional reactors, enhancing reaction rates and process efficiency.

Process intensification

Microreactors enable process intensification by offering enhanced heat and mass transfer rates, superior safety, and precise reaction control compared to traditional reactors, resulting in higher efficiency and reduced reactor volume.

Scalability challenges

Microreactors face scalability challenges due to limited production capacity per unit compared to traditional reactors, which benefit from larger-scale continuous operation but require significant capital investment and infrastructure expansion.

Flow chemistry

Microreactors enhance flow chemistry by providing superior heat transfer, precise reaction control, and increased safety compared to traditional batch reactors.

Channel fouling

Microreactors experience significantly reduced channel fouling compared to traditional reactors due to their smaller channel dimensions and enhanced flow control, which minimize deposit accumulation and improve maintenance efficiency.

Continuous processing

Microreactors enable more efficient continuous processing than traditional batch reactors by offering enhanced heat and mass transfer, precise reaction control, and scalable modular design.

Microreactors vs Traditional reactors Infographic

njnir.com

njnir.com