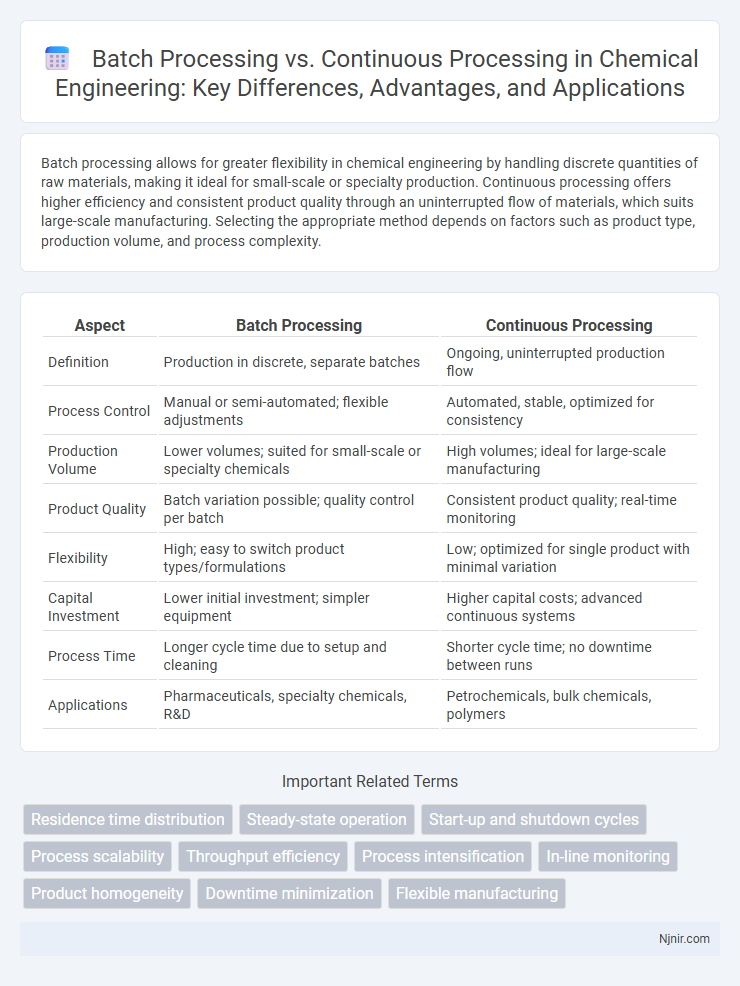

Batch processing allows for greater flexibility in chemical engineering by handling discrete quantities of raw materials, making it ideal for small-scale or specialty production. Continuous processing offers higher efficiency and consistent product quality through an uninterrupted flow of materials, which suits large-scale manufacturing. Selecting the appropriate method depends on factors such as product type, production volume, and process complexity.

Table of Comparison

| Aspect | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Production in discrete, separate batches | Ongoing, uninterrupted production flow |

| Process Control | Manual or semi-automated; flexible adjustments | Automated, stable, optimized for consistency |

| Production Volume | Lower volumes; suited for small-scale or specialty chemicals | High volumes; ideal for large-scale manufacturing |

| Product Quality | Batch variation possible; quality control per batch | Consistent product quality; real-time monitoring |

| Flexibility | High; easy to switch product types/formulations | Low; optimized for single product with minimal variation |

| Capital Investment | Lower initial investment; simpler equipment | Higher capital costs; advanced continuous systems |

| Process Time | Longer cycle time due to setup and cleaning | Shorter cycle time; no downtime between runs |

| Applications | Pharmaceuticals, specialty chemicals, R&D | Petrochemicals, bulk chemicals, polymers |

Introduction to Batch and Continuous Processing

Batch processing involves handling groups of data or materials in discrete, separate lots, allowing for efficient management of large volumes with consistent quality control. Continuous processing operates on a nonstop flow of materials or data, optimizing production speed and minimizing downtime by maintaining constant operational conditions. Each method offers distinct advantages depending on the industry, production goals, and product specifications.

Fundamental Differences Between Batch and Continuous Methods

Batch processing involves handling a finite quantity of material in discrete steps, allowing for flexibility in production and easier quality control. Continuous processing operates without interruption, maintaining a constant production flow that maximizes efficiency and consistency in output. The fundamental difference lies in batch's segmented, time-bound approach versus continuous's steady, uninterrupted operation.

Advantages of Batch Processing in Chemical Engineering

Batch processing in chemical engineering offers significant advantages such as enhanced flexibility in production, enabling the formulation of multiple products in varying quantities without extensive equipment changes. It allows precise control over reaction times and conditions, improving product quality and consistency for specialty chemicals and pharmaceuticals. Cost-effective for small to medium-scale production, batch processing minimizes downtime and waste, optimizing resource utilization in complex chemical manufacturing workflows.

Advantages of Continuous Processing in Chemical Manufacturing

Continuous processing in chemical manufacturing enhances product consistency by maintaining steady-state conditions, reducing batch-to-batch variability. It improves operational efficiency through uninterrupted production, optimizing resource utilization and minimizing downtime. This approach also offers better scalability and faster response to market demand, enabling more agile and cost-effective manufacturing processes.

Process Flexibility and Scalability Comparison

Batch processing offers high process flexibility by allowing customization for different product formulations in discrete runs, making it ideal for varied production demands. Continuous processing excels in scalability, providing consistent output with minimal downtime and efficient resource utilization suited for large-scale manufacturing. The choice hinges on balancing flexibility needs with production volume and speed requirements.

Efficiency and Throughput Analysis

Batch processing enables high efficiency in handling large volumes of data by grouping tasks into discrete units, optimizing resource allocation and minimizing idle time. Continuous processing offers superior throughput through real-time data handling and reduced latency, enhancing performance in time-sensitive applications. Evaluating both methods reveals that batch processing excels in controlled environments with predictable workloads, while continuous processing maximizes efficiency under dynamic conditions requiring constant data flow.

Quality Control and Product Consistency

Batch processing allows for thorough quality control at each stage, enabling detection and correction of defects before proceeding, which enhances product consistency within individual batches. Continuous processing relies on real-time monitoring and automated quality control systems to maintain uniformity, ensuring consistent product quality throughout extended production runs. Both methods leverage advanced sensors and data analytics to optimize process parameters and minimize variability, directly impacting overall product reliability.

Cost Considerations: Capital and Operational Expenses

Batch processing typically incurs higher capital costs due to the need for larger storage and specialized equipment for handling discrete production runs. Operational expenses in batch processing can be elevated by labor-intensive setup times, cleaning, and downtime between batches. Continuous processing often demonstrates lower operational costs through streamlined workflows and reduced material waste, but requires significant upfront investment in advanced control systems and infrastructure.

Safety and Environmental Impact

Batch processing offers enhanced safety control by isolating operations, reducing the risk of hazardous mixture and allowing easier containment of spills or leaks, which minimizes environmental contamination. Continuous processing enables consistent monitoring and stable operating conditions, lowering the chance of sudden incidents and reducing waste generation through optimized resource use. Both methods require tailored safety measures and environmental controls based on chemical properties and production scale to effectively minimize risks and impact.

Choosing the Optimal Processing Method for Chemical Applications

Batch processing allows precise control over reaction conditions and is ideal for small-scale or multi-product chemical applications requiring flexibility and customization. Continuous processing offers enhanced efficiency, consistent product quality, and scalability, making it suitable for large-scale production with steady demand. Selecting the optimal method depends on factors like production volume, process complexity, desired product consistency, and cost-effectiveness in chemical manufacturing.

Residence time distribution

Residence time distribution in batch processing shows uniformity with fixed processing intervals, whereas continuous processing exhibits variable residence times impacting product consistency and throughput efficiency.

Steady-state operation

Continuous processing maintains steady-state operation by constantly feeding raw materials and producing output, while batch processing operates in discrete cycles with variable conditions between runs.

Start-up and shutdown cycles

Batch processing involves frequent start-up and shutdown cycles causing downtime and increased wear, while continuous processing maintains steady operations with minimal interruptions, enhancing efficiency and equipment longevity.

Process scalability

Batch processing offers limited scalability due to fixed batch sizes and processing intervals, while continuous processing enables dynamic scalability by handling data streams in real-time, optimizing throughput and resource utilization.

Throughput efficiency

Continuous processing achieves higher throughput efficiency than batch processing by enabling nonstop material flow and minimizing downtime.

Process intensification

Process intensification enhances both batch and continuous processing by increasing reaction efficiency, reducing equipment size, and improving energy utilization, with continuous processing offering superior scalability and consistency for intensified operations.

In-line monitoring

In-line monitoring in batch processing enables periodic quality checks at defined stages, while continuous processing utilizes real-time in-line sensors for constant product quality assessment and process control.

Product homogeneity

Batch processing suits heterogeneous products with varied specifications, while continuous processing excels in producing homogeneous products with consistent quality.

Downtime minimization

Continuous processing minimizes downtime by maintaining constant operation, whereas batch processing experiences significant downtime during setup and transition between batches.

Flexible manufacturing

Flexible manufacturing benefits from continuous processing by enabling real-time production adjustments, whereas batch processing offers versatility for varied product runs but with longer changeover times.

Batch processing vs continuous processing Infographic

njnir.com

njnir.com