Green hydrogen, produced through electrolysis powered by renewable energy sources, offers a sustainable and carbon-neutral alternative to grey hydrogen, which is derived from natural gas with significant CO2 emissions. The shift to green hydrogen mitigates environmental impact by eliminating fossil fuel dependency and reducing greenhouse gas emissions. Advancements in electrolyzer technology and renewable energy integration are critical for scaling green hydrogen production to meet industrial and energy demands.

Table of Comparison

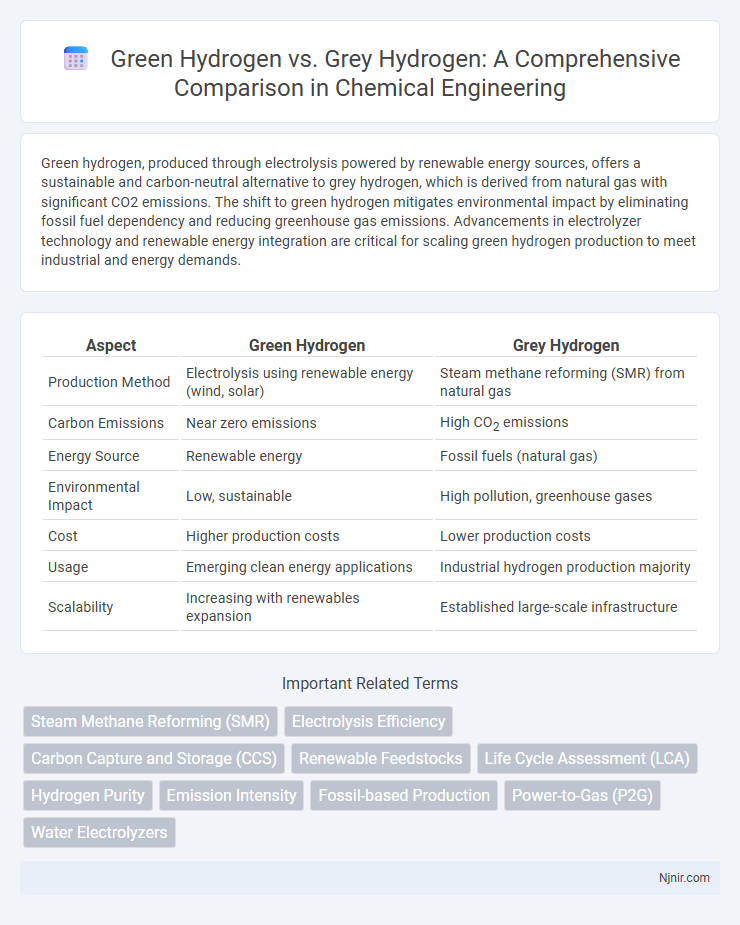

| Aspect | Green Hydrogen | Grey Hydrogen |

|---|---|---|

| Production Method | Electrolysis using renewable energy (wind, solar) | Steam methane reforming (SMR) from natural gas |

| Carbon Emissions | Near zero emissions | High CO2 emissions |

| Energy Source | Renewable energy | Fossil fuels (natural gas) |

| Environmental Impact | Low, sustainable | High pollution, greenhouse gases |

| Cost | Higher production costs | Lower production costs |

| Usage | Emerging clean energy applications | Industrial hydrogen production majority |

| Scalability | Increasing with renewables expansion | Established large-scale infrastructure |

Introduction to Green and Grey Hydrogen

Green hydrogen is produced through electrolysis powered by renewable energy sources, resulting in zero carbon emissions and a sustainable energy carrier. Grey hydrogen, on the other hand, is derived from natural gas or coal through steam methane reforming or gasification, which releases significant CO2 emissions. The shift from grey to green hydrogen is critical for reducing the carbon footprint of hydrogen production and advancing clean energy technologies.

Production Processes: Green vs Grey Hydrogen

Green hydrogen is produced through electrolysis, splitting water into hydrogen and oxygen using renewable energy sources like solar or wind power, resulting in zero carbon emissions during production. Grey hydrogen is generated primarily via steam methane reforming (SMR) of natural gas, releasing significant amounts of CO2 as a byproduct. The key distinction lies in green hydrogen's sustainable, low-carbon method compared to grey hydrogen's reliance on fossil fuels and associated greenhouse gas emissions.

Environmental Impact Comparison

Green hydrogen, produced via electrolysis using renewable energy sources, generates negligible greenhouse gas emissions, significantly reducing carbon footprint compared to grey hydrogen, which is derived from natural gas through steam methane reforming and emits substantial amounts of CO2. The environmental impact of green hydrogen is minimal, supporting decarbonization efforts in heavy industries and transportation, while grey hydrogen contributes heavily to air pollution and climate change. Transitioning to green hydrogen is essential for achieving global net-zero emissions targets and mitigating environmental degradation caused by fossil fuel dependence.

Economic Considerations and Cost Analysis

Green hydrogen production incurs higher upfront capital expenditure due to the cost of electrolysis and renewable energy infrastructure, while grey hydrogen relies on cheaper natural gas feedstocks but faces volatility in fossil fuel prices. Operational costs for green hydrogen are expected to decrease as renewable energy prices continue to decline and electrolyzer technology improves, enhancing its economic competitiveness over grey hydrogen. Long-term economic considerations include carbon pricing and regulatory frameworks that may increase the cost of grey hydrogen production, making green hydrogen a more viable option in decarbonized energy markets.

Energy Efficiency and Resource Utilization

Green hydrogen, produced via electrolysis powered by renewable energy, offers higher energy efficiency through the direct conversion of electricity into hydrogen without carbon emissions. Grey hydrogen, generated from natural gas reforming, has lower energy efficiency due to significant energy losses and carbon dioxide byproducts, impacting resource utilization negatively. Utilizing green hydrogen optimizes renewable energy resources while reducing environmental impact, making it a more sustainable choice compared to grey hydrogen's reliance on fossil fuels and non-renewable resources.

Technological Challenges and Innovations

Green hydrogen production faces significant technological challenges, including the high cost and efficiency limitations of electrolyzers used to split water into hydrogen and oxygen. Innovations in proton exchange membrane (PEM) and solid oxide electrolyzer cells (SOEC) aim to improve efficiency and reduce energy consumption. In contrast, grey hydrogen relies on steam methane reforming, which emits substantial CO2, driving research into carbon capture and storage (CCS) to mitigate environmental impact.

Infrastructure and Supply Chain Differences

Green hydrogen production relies heavily on renewable energy sources like solar and wind, necessitating infrastructure investments in electrolysis plants and integrated power grids for efficient energy conversion. Grey hydrogen, derived from natural gas via steam methane reforming, depends on established fossil fuel supply chains and centralized production facilities with extensive pipeline networks for distribution. The supply chain for green hydrogen faces challenges in scaling renewable energy capacity and developing storage technologies, whereas grey hydrogen's infrastructure is more mature but associated with higher carbon emissions and regulatory pressures.

Policy, Regulation, and Government Support

Green hydrogen benefits from increasing government support through policies promoting renewable energy integration and carbon neutrality targets, such as the EU Hydrogen Strategy and the U.S. Hydrogen Shot initiative. Grey hydrogen faces stricter regulations and carbon pricing mechanisms aimed at reducing fossil fuel reliance and lowering greenhouse gas emissions, including the EU Emissions Trading System and carbon tax frameworks. Government subsidies and incentives favor green hydrogen production technologies like electrolysis, accelerating market adoption and infrastructure development.

Applications in Industry and Energy Sectors

Green hydrogen, produced through electrolysis powered by renewable energy, serves as a sustainable fuel in industries like steel manufacturing and chemical production due to its zero carbon emissions. Grey hydrogen, derived from natural gas via steam methane reforming, remains prevalent in oil refining and ammonia synthesis but contributes significantly to CO2 emissions. Transitioning from grey to green hydrogen in energy sectors can drastically reduce industrial carbon footprints and support the global shift toward decarbonization.

Future Outlook and Market Trends

Green hydrogen, produced via electrolysis powered by renewable energy, is positioned for significant market growth as governments and industries prioritize decarbonization to meet climate targets. The future outlook forecasts an exponential increase in green hydrogen capacity driven by falling electrolyzer costs and expanding renewable infrastructure. Grey hydrogen, derived from natural gas with high carbon emissions, faces declining demand due to stricter environmental regulations and increasing carbon pricing, accelerating the shift toward sustainable hydrogen solutions.

Steam Methane Reforming (SMR)

Green hydrogen is produced using electrolysis powered by renewable energy sources, while grey hydrogen is generated through steam methane reforming (SMR) of natural gas, emitting significant CO2.

Electrolysis Efficiency

Green hydrogen produced via electrolysis achieves efficiencies of 60-80%, significantly higher than grey hydrogen generated from steam methane reforming, which lacks electrolytic processes.

Carbon Capture and Storage (CCS)

Green hydrogen production generates zero carbon emissions, whereas grey hydrogen relies on fossil fuels but can reduce its environmental impact through Carbon Capture and Storage (CCS) technology that captures up to 90% of emitted CO2.

Renewable Feedstocks

Green hydrogen is produced using renewable feedstocks like water electrolysis powered by solar or wind energy, whereas grey hydrogen relies on fossil fuels such as natural gas, resulting in higher carbon emissions.

Life Cycle Assessment (LCA)

Green hydrogen demonstrates significantly lower environmental impacts in Life Cycle Assessment (LCA) compared to grey hydrogen due to its renewable energy sources and minimal greenhouse gas emissions during production.

Hydrogen Purity

Green hydrogen typically achieves higher purity levels above 99.99% due to renewable electrolysis, whereas grey hydrogen often contains impurities like methane and carbon monoxide from fossil fuel-based steam methane reforming.

Emission Intensity

Green hydrogen produces near-zero carbon emissions by using renewable energy for electrolysis, whereas grey hydrogen generates approximately 10-12 kg CO2 per kg of hydrogen due to fossil fuel-based steam methane reforming.

Fossil-based Production

Green hydrogen is produced through electrolysis powered by renewable energy, whereas grey hydrogen relies on fossil-based production methods like natural gas reforming, resulting in higher carbon emissions.

Power-to-Gas (P2G)

Green hydrogen, produced via Power-to-Gas (P2G) technology using renewable energy sources, offers a sustainable alternative to grey hydrogen which is derived from fossil fuels through steam methane reforming, significantly reducing carbon emissions in energy systems.

Water Electrolyzers

Green hydrogen produced via water electrolyzers emits zero carbon by using renewable electricity, unlike grey hydrogen which relies on fossil fuels and emits significant CO2 during production.

Green Hydrogen vs Grey Hydrogen Infographic

njnir.com

njnir.com