Aspen Plus offers comprehensive process simulation with robust thermodynamic models, making it ideal for complex chemical reactions and large-scale process design. ChemCAD provides a user-friendly interface and flexibility suited for quick process evaluations and detailed equipment design. Both tools support steady-state and dynamic simulations, but Aspen Plus excels in advanced process optimization, while ChemCAD is preferred for ease of use in batch and continuous process modeling.

Table of Comparison

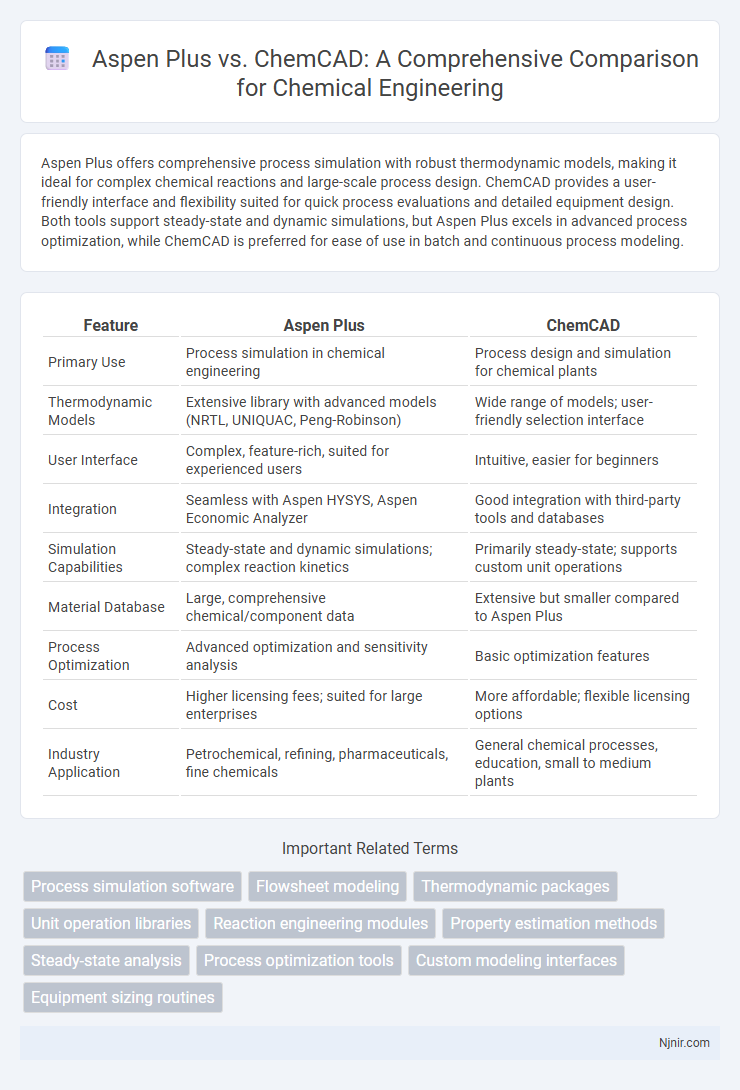

| Feature | Aspen Plus | ChemCAD |

|---|---|---|

| Primary Use | Process simulation in chemical engineering | Process design and simulation for chemical plants |

| Thermodynamic Models | Extensive library with advanced models (NRTL, UNIQUAC, Peng-Robinson) | Wide range of models; user-friendly selection interface |

| User Interface | Complex, feature-rich, suited for experienced users | Intuitive, easier for beginners |

| Integration | Seamless with Aspen HYSYS, Aspen Economic Analyzer | Good integration with third-party tools and databases |

| Simulation Capabilities | Steady-state and dynamic simulations; complex reaction kinetics | Primarily steady-state; supports custom unit operations |

| Material Database | Large, comprehensive chemical/component data | Extensive but smaller compared to Aspen Plus |

| Process Optimization | Advanced optimization and sensitivity analysis | Basic optimization features |

| Cost | Higher licensing fees; suited for large enterprises | More affordable; flexible licensing options |

| Industry Application | Petrochemical, refining, pharmaceuticals, fine chemicals | General chemical processes, education, small to medium plants |

Overview of Aspen Plus and ChemCAD

Aspen Plus and ChemCAD are leading process simulation software extensively used in chemical engineering for modeling, optimization, and design of chemical processes. Aspen Plus boasts robust thermodynamic models and extensive component libraries, making it ideal for complex process flowsheets, while ChemCAD offers user-friendly interfaces and flexible customization suitable for small to medium-scale projects. Both platforms support dynamic simulation, energy integration, and environmental compliance, but Aspen Plus typically excels in rigorous steady-state simulations whereas ChemCAD emphasizes ease of use and cost-effective solutions.

User Interface and Usability Comparison

Aspen Plus offers a highly detailed and complex user interface tailored for advanced process simulations, requiring a steeper learning curve but providing extensive customization. ChemCAD features a more intuitive and user-friendly interface, designed for quick setup and straightforward operation, which suits engineers needing faster results with less training. Usability-wise, ChemCAD excels in ease of use for fundamental simulations, while Aspen Plus remains preferred for comprehensive, in-depth process modeling and optimization.

Supported Unit Operations and Libraries

Aspen Plus offers an extensive library of unit operations, including distillation, absorption, heat exchange, and reactive processes, making it suitable for complex chemical process simulations. ChemCAD provides a comprehensive set of unit operations with strengths in steady-state and dynamic simulations, supporting modular process design and detailed thermodynamic models. Both platforms support custom unit operations and integrate extensive physical property databases, but Aspen Plus excels in advanced reaction modeling and process optimization capabilities.

Thermodynamic Models and Data Handling

Aspen Plus offers an extensive library of thermodynamic models including NRTL, UNIQUAC, Peng-Robinson, and Soave-Redlich-Kwong, supporting complex electrolyte and polymer systems with comprehensive databanks. ChemCAD provides flexibility in thermodynamic modeling with models such as Wilson, UNIFAC, and Redlich-Kwong, emphasizing user-defined components and custom property methods. Data handling in Aspen Plus integrates robust database management with real-time data validation, whereas ChemCAD allows dynamic data modification and seamless import/export capabilities for process simulation customization.

Simulation Capabilities and Accuracy

Aspen Plus offers advanced simulation capabilities with a comprehensive database for chemical processes, ensuring high accuracy in thermodynamic models and reaction kinetics, which is essential for complex process designs. ChemCAD provides flexible and intuitive simulation tools tailored for steady-state and dynamic process modeling, with reliable results in distillation, heat exchange, and others, though it may lack some detailed unit operation models compared to Aspen Plus. Both software platforms excel in process simulation accuracy but Aspen Plus is preferred for rigorous chemical process analysis, while ChemCAD is favored for user-friendly interface and faster setup times.

Integration with Other Engineering Tools

Aspen Plus offers robust integration capabilities with a wide range of engineering software, including MATLAB, Excel, and various process simulation tools, enabling seamless data exchange and workflow automation. ChemCAD supports interoperability with spreadsheets, custom user interfaces, and third-party applications through COM and DLL interfaces, facilitating flexible process modeling and optimization. Both platforms provide essential connectivity for multidisciplinary engineering teams, but Aspen Plus's extensive API and cloud-based collaboration tools often deliver more comprehensive integration options for large-scale projects.

Customization and Scripting Features

Aspen Plus offers advanced customization through its Aspen Custom Modeler and extensive API support, enabling users to create tailored process models and automate simulations with proprietary scripting languages. ChemCAD provides flexible scripting capabilities using VBA and extensive macro functions, allowing for process optimization and integration with third-party software tools. Both platforms support user-defined unit operations, but Aspen Plus delivers deeper customization for complex chemical processes, while ChemCAD emphasizes user-friendly script automation for enhanced workflow efficiency.

Industry Applications and Case Studies

Aspen Plus is widely utilized in chemical process industries including petrochemicals, pharmaceuticals, and polymers due to its robust thermodynamic models and advanced process simulation capabilities, enabling complex reaction engineering and separation processes optimization. ChemCAD finds strong application in refining, gas processing, and specialty chemical production with user-friendly interfaces and real-time plant data integration, supporting dynamic simulation and operator training. Case studies highlight Aspen Plus's effectiveness in large-scale process design and optimization projects, while ChemCAD excels in troubleshooting, operational simulations, and cost reduction in mid-sized plants.

Licensing, Cost, and Technical Support

Aspen Plus offers flexible licensing options, including node-locked and concurrent licenses, with pricing typically higher due to its advanced simulation capabilities, targeting large-scale industrial users; technical support includes comprehensive training, extensive documentation, and premium customer service. ChemCAD provides more affordable licensing models suitable for small to medium enterprises, often featuring perpetual licenses and subscription plans, accompanied by responsive technical support with direct access to experts and regular software updates. Both software packages emphasize robust support but differ significantly in cost structure and licensing flexibility, making Aspen Plus ideal for complex, large-scale projects and ChemCAD more accessible for budget-conscious users.

Future Trends and Software Development

Aspen Plus and ChemCAD are advancing with enhanced integration of artificial intelligence and machine learning to optimize process simulation accuracy and efficiency. Both software platforms are incorporating cloud computing capabilities to facilitate collaborative engineering and scalable computational resources. Future trends emphasize expanded modularity and open-source interoperability to support customization and seamless integration with Industry 4.0 technologies.

Process simulation software

Aspen Plus offers advanced thermodynamic modeling and extensive chemical databases for complex process simulations, while ChemCAD provides user-friendly interfaces and customizable tools ideal for detailed chemical engineering process design and optimization.

Flowsheet modeling

Aspen Plus offers advanced, user-friendly flowsheet modeling with extensive thermodynamic packages and rigorous unit operation libraries, while ChemCAD provides flexible, customizable flowsheet modeling emphasizing cost-effective process simulation and intuitive interface for chemical engineers.

Thermodynamic packages

Aspen Plus offers a wider variety of thermodynamic packages including NRTL, UNIQUAC, and Peng-Robinson suitable for complex chemical processes, while ChemCAD primarily focuses on commonly used models like Soave-Redlich-Kwong and Peng-Robinson optimized for vapor-liquid equilibrium calculations.

Unit operation libraries

Aspen Plus offers an extensive and highly detailed unit operation library ideal for complex chemical process simulations, while ChemCAD provides a more user-friendly and flexible unit operation library suited for quick process design and troubleshooting.

Reaction engineering modules

Aspen Plus offers advanced reaction engineering modules with detailed kinetics and thermodynamics modeling, while ChemCAD provides user-friendly reaction simulation tools optimized for process design and optimization.

Property estimation methods

Aspen Plus utilizes advanced EOS models and comprehensive databases for property estimation, while ChemCAD emphasizes flexible regression methods and customizable property parameters for tailored process simulations.

Steady-state analysis

Aspen Plus offers comprehensive steady-state analysis with extensive thermodynamic models and process simulation capabilities, while ChemCAD provides user-friendly steady-state simulation focused on customizable process flows and cost-effective solutions.

Process optimization tools

Aspen Plus offers advanced process optimization tools with robust steady-state and dynamic modeling capabilities, while ChemCAD provides user-friendly optimization features tailored for flexible process simulation and rapid scenario analysis.

Custom modeling interfaces

Aspen Plus offers advanced custom modeling interfaces with extensive user-defined model integration via Aspen Custom Modeler, while ChemCAD provides flexible custom modeling through its built-in scripting and API support, allowing tailored process simulations.

Equipment sizing routines

Aspen Plus offers advanced, customizable equipment sizing routines with extensive thermodynamic models, while ChemCAD provides user-friendly, flexible sizing tools optimized for process simulation and equipment design efficiency.

Aspen Plus vs ChemCAD Infographic

njnir.com

njnir.com