Fouling mitigation involves strategies to reduce the impact and accumulation of deposits on heat transfer surfaces during operation, aiming to maintain efficiency and extend equipment lifespan. Fouling prevention focuses on proactive measures such as selecting appropriate materials, optimizing process conditions, and implementing surface treatments to inhibit the initial formation of fouling layers. Effective chemical engineering requires balancing both approaches to enhance system performance and minimize downtime.

Table of Comparison

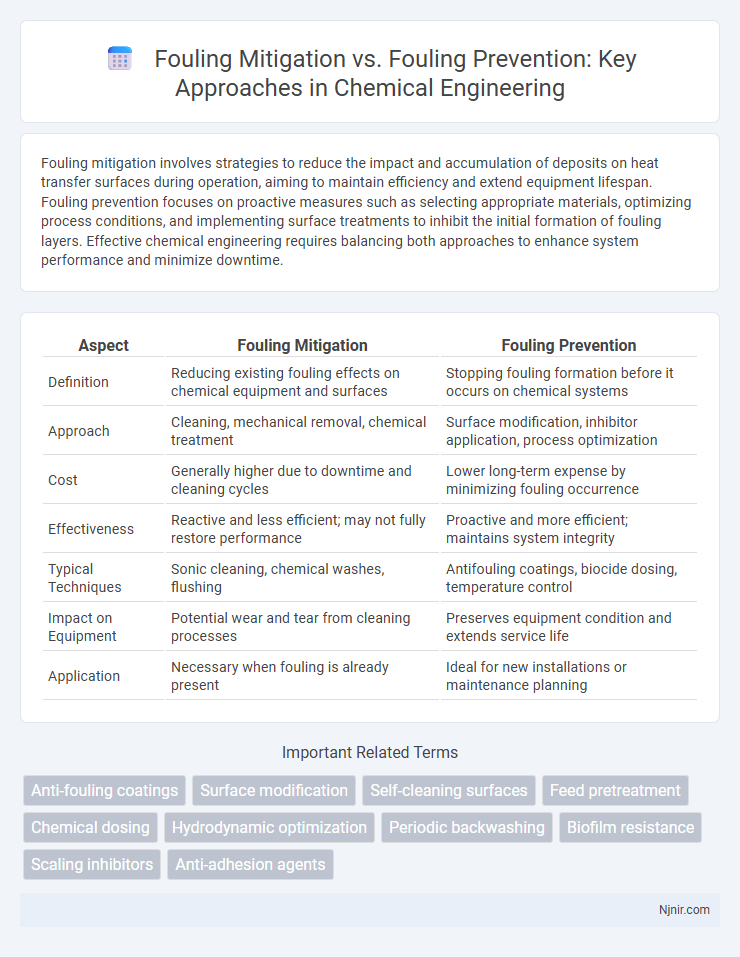

| Aspect | Fouling Mitigation | Fouling Prevention |

|---|---|---|

| Definition | Reducing existing fouling effects on chemical equipment and surfaces | Stopping fouling formation before it occurs on chemical systems |

| Approach | Cleaning, mechanical removal, chemical treatment | Surface modification, inhibitor application, process optimization |

| Cost | Generally higher due to downtime and cleaning cycles | Lower long-term expense by minimizing fouling occurrence |

| Effectiveness | Reactive and less efficient; may not fully restore performance | Proactive and more efficient; maintains system integrity |

| Typical Techniques | Sonic cleaning, chemical washes, flushing | Antifouling coatings, biocide dosing, temperature control |

| Impact on Equipment | Potential wear and tear from cleaning processes | Preserves equipment condition and extends service life |

| Application | Necessary when fouling is already present | Ideal for new installations or maintenance planning |

Introduction to Fouling in Chemical Engineering

Fouling in chemical engineering refers to the undesirable accumulation of materials on equipment surfaces, leading to reduced efficiency and increased operational costs. Fouling mitigation involves strategies to control and remove deposits after they form, while fouling prevention focuses on measures to avoid the initial formation of fouling through design optimization and surface treatments. Understanding the distinct approaches helps improve process reliability and extends equipment lifespan in industries such as petrochemical refining and heat exchanger operations.

Defining Fouling Prevention and Mitigation

Fouling prevention involves proactive strategies to inhibit the initial formation of deposits on surfaces, employing methods such as surface coatings, material selection, and operational adjustments to maintain optimal system performance. Fouling mitigation refers to reactive techniques applied after fouling occurs, including mechanical cleaning, chemical treatments, and flushing, aimed at reducing fouling effects and restoring efficiency. Both approaches are critical in industrial systems, with prevention reducing incidence rates and mitigation minimizing operational disruptions caused by fouling deposits.

Root Causes and Types of Fouling

Fouling prevention targets the root causes by addressing factors such as surface roughness, chemical composition, and fluid properties to inhibit the initial adhesion of contaminants. Fouling mitigation focuses on managing existing deposits through mechanical cleaning, chemical treatment, or operational adjustments to control fouling types like biological, chemical, particulate, and scaling. Understanding the differences in root causes and fouling types is crucial for selecting effective prevention or mitigation strategies in industrial processes.

Mechanisms of Fouling Formation

Fouling mitigation involves controlling the buildup of contaminants on surfaces after fouling formation, primarily through mechanical cleaning, chemical treatment, or operational adjustments. Fouling prevention targets the initial mechanisms of fouling formation, such as temperature gradients, particle adhesion, or biofilm development, by modifying surface properties or optimizing process conditions to inhibit deposition. Understanding mechanisms like nucleation, adsorption, and consolidation enables more effective strategies in reducing the impact of fouling on system performance.

Fouling Prevention Strategies: Proactive Approaches

Fouling prevention strategies emphasize proactive measures such as surface modification, chemical dosing, and operational optimization to inhibit the initial adhesion of contaminants. Employing advanced coatings like hydrophobic or antimicrobial layers reduces biofilm formation and particulate buildup on industrial equipment. Integrating real-time monitoring systems enables early detection of fouling tendencies, allowing timely adjustments to maintain optimal performance and extend maintenance intervals.

Fouling Mitigation Methods: Reactive Solutions

Fouling mitigation methods involve reactive solutions aimed at controlling and reducing fouling after it has occurred, primarily through mechanical cleaning, chemical treatments, and process adjustments. Mechanical cleaning techniques like pigging, brushing, or high-pressure water jets physically remove deposits from surfaces, while chemical treatments utilize detergents, solvents, or biocides to dissolve or inhibit fouling agents. Process modifications, such as altering flow velocity or temperature, help disrupt fouling formation, making reactive fouling mitigation essential in maintaining operational efficiency in industries like oil and gas, water treatment, and heat exchangers.

Comparative Analysis: Prevention vs Mitigation

Fouling prevention focuses on designing systems and selecting materials that inhibit foulant adhesion, reducing maintenance frequency and operational downtime. Fouling mitigation involves active cleaning methods such as chemical dosing, mechanical cleaning, or ultrasonic waves to remove deposits after fouling occurs, often incurring higher operational costs. Comparative analysis highlights prevention as a cost-effective, long-term strategy, while mitigation is crucial for managing fouling when prevention fails or is impractical.

Economic Impact of Fouling Control Measures

Fouling mitigation strategies often incur lower upfront costs but may lead to higher long-term operational expenses due to frequent cleaning and reduced equipment efficiency, impacting overall profitability. Fouling prevention techniques, though typically involving higher initial investments in advanced coatings or design modifications, offer sustained economic benefits by minimizing downtime and maintenance costs. Effective fouling control measures balance the trade-off between immediate expenditures and long-term savings, optimizing asset lifespan and operational performance in industrial applications.

Advances in Anti-Fouling Technologies

Advances in anti-fouling technologies emphasize fouling prevention techniques, such as surface modifications and environmentally friendly coatings that inhibit biofilm formation and organism attachment. Fouling mitigation strategies focus on mechanical cleaning and chemical treatments to remove existing deposits, minimizing equipment downtime and maintaining operational efficiency. Innovations in nanomaterials and self-healing surfaces have significantly enhanced both prevention and mitigation, reducing maintenance costs and improving long-term system performance in maritime, water treatment, and industrial applications.

Future Trends in Fouling Management

Future trends in fouling management emphasize advanced fouling mitigation techniques such as smart coatings and real-time monitoring systems that adapt to changing environmental conditions. Fouling prevention increasingly relies on sustainable materials and bio-inspired surfaces that reduce the initial attachment of organisms without harmful chemicals. Integration of AI-driven predictive maintenance and nanotechnology promises to enhance both fouling prevention and mitigation by optimizing cleaning schedules and surface properties.

Anti-fouling coatings

Anti-fouling coatings primarily focus on fouling prevention by creating surfaces that inhibit organism attachment, whereas fouling mitigation involves strategies and treatments applied after fouling has occurred to reduce its impact.

Surface modification

Surface modification techniques such as polymer grafting and plasma treatment offer effective fouling mitigation by altering surface properties to reduce adhesion, while fouling prevention focuses on creating inherently non-fouling surfaces through chemical or physical modifications.

Self-cleaning surfaces

Self-cleaning surfaces enhance fouling mitigation by actively removing contaminants, while fouling prevention relies on surface properties to inhibit initial adhesion.

Feed pretreatment

Effective feed pretreatment minimizes fouling by removing particulates and contaminants, enhancing fouling mitigation compared to relying solely on fouling prevention methods.

Chemical dosing

Chemical dosing targets fouling mitigation by reducing deposit accumulation, while fouling prevention relies on optimized dosing strategies to inhibit initial foulant adhesion and formation.

Hydrodynamic optimization

Hydrodynamic optimization enhances fouling mitigation by improving fluid flow patterns to reduce deposit accumulation, whereas fouling prevention focuses on material selection and surface treatments to inhibit foulant adhesion.

Periodic backwashing

Periodic backwashing effectively mitigates fouling by removing accumulated contaminants from filtration systems, whereas fouling prevention aims to inhibit contaminant buildup before it occurs.

Biofilm resistance

Biofilm resistance in fouling mitigation involves removing established microbial layers, whereas fouling prevention focuses on inhibiting initial biofilm formation through surface modifications or antimicrobial coatings.

Scaling inhibitors

Scaling inhibitors are essential in fouling mitigation by disrupting scale formation and preventing surface deposition, whereas fouling prevention relies on proactive measures such as maintaining optimal operating conditions to reduce scaling risk.

Anti-adhesion agents

Anti-adhesion agents effectively reduce fouling by minimizing surface adhesion of contaminants, providing a proactive fouling mitigation strategy distinct from fouling prevention methods that focus on blocking fouling initiation.

Fouling mitigation vs Fouling prevention Infographic

njnir.com

njnir.com