CFD simulation enables precise modeling of fluid flow and heat transfer in chemical engineering processes, offering detailed insights that are difficult to obtain experimentally. Experimental validation remains essential to verify and calibrate CFD models, ensuring accuracy and reliability of predictions in real-world applications. Combining both approaches enhances process optimization and scale-up efficiency in chemical reactor design.

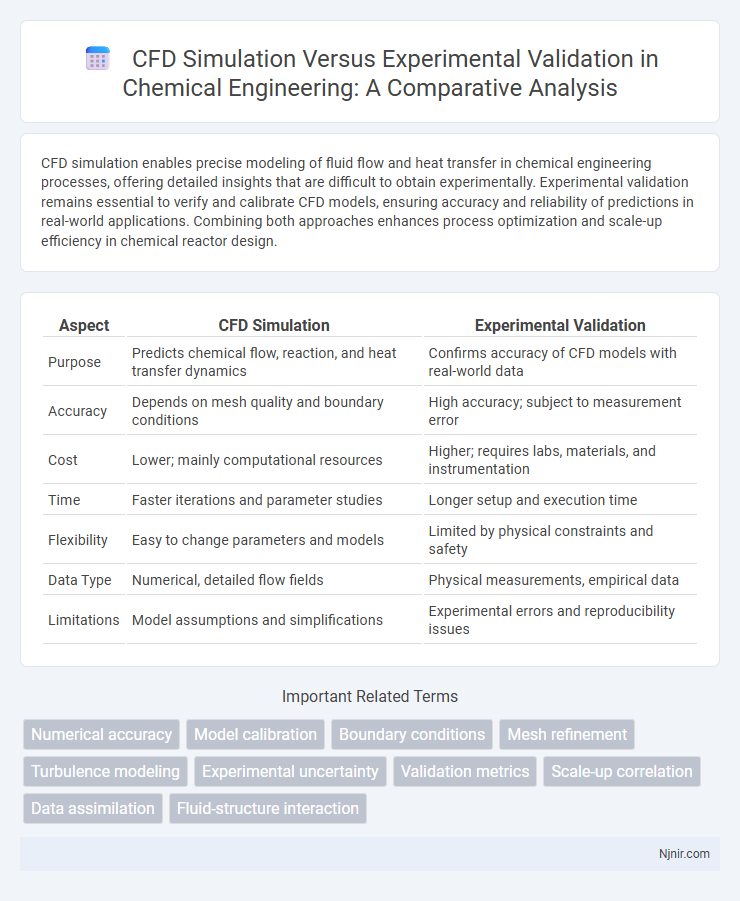

Table of Comparison

| Aspect | CFD Simulation | Experimental Validation |

|---|---|---|

| Purpose | Predicts chemical flow, reaction, and heat transfer dynamics | Confirms accuracy of CFD models with real-world data |

| Accuracy | Depends on mesh quality and boundary conditions | High accuracy; subject to measurement error |

| Cost | Lower; mainly computational resources | Higher; requires labs, materials, and instrumentation |

| Time | Faster iterations and parameter studies | Longer setup and execution time |

| Flexibility | Easy to change parameters and models | Limited by physical constraints and safety |

| Data Type | Numerical, detailed flow fields | Physical measurements, empirical data |

| Limitations | Model assumptions and simplifications | Experimental errors and reproducibility issues |

Introduction to CFD in Chemical Engineering

Computational Fluid Dynamics (CFD) in chemical engineering enables detailed analysis of fluid flow, heat transfer, and chemical reactions within reactors and process equipment, offering insights difficult to achieve through physical experiments alone. Experimental validation remains critical to ensure CFD model accuracy, providing essential data to calibrate, verify, and refine simulations against real-world conditions. The integration of CFD with experimental methods enhances process optimization, scale-up, and safety analysis in chemical engineering applications.

Fundamentals of Experimental Validation

Experimental validation ensures the accuracy of CFD simulations by comparing numerical results with real-world data obtained through physical testing. Key fundamentals include precise measurement techniques, controlled test conditions, and repeatability to minimize uncertainty and validate model assumptions. Integrating detailed experimental data, such as velocity fields and pressure distributions, enhances the reliability and predictive capability of CFD models.

Key Differences Between CFD Simulation and Experimental Methods

CFD simulation offers detailed, customizable flow field data through numerical methods, while experimental methods provide physical measurements with real-world accuracy and inherent uncertainties. CFD enables rapid iteration and analysis across varying conditions without physical prototypes, contrasting with the often resource-intensive and time-consuming nature of experiments. Experimental validation remains crucial to verify CFD models, ensuring reliability by comparing simulated results against measured data under controlled setups.

Advantages of CFD Simulations

CFD simulations offer precise control over variables and allow detailed analysis of fluid flow patterns, which are often difficult to capture in experimental setups. They reduce costs and time by eliminating the need for physical prototypes while enabling rapid iterations and optimization of designs. High-resolution CFD results enhance understanding of complex phenomena such as turbulence, heat transfer, and chemical reactions, providing insights that support informed engineering decisions.

Limitations of CFD in Chemical Engineering

CFD simulation in chemical engineering faces limitations such as model assumptions that may oversimplify complex fluid dynamics and reaction kinetics, leading to discrepancies from real-world behavior. Turbulence modeling, multi-phase flow representation, and chemical reaction mechanisms often involve approximations that impact accuracy and predictive capability. Experimental validation remains essential to identify these gaps, calibrate models, and ensure reliable scale-up from laboratory to industrial processes.

Role of Experimental Validation in Process Optimization

Experimental validation plays a crucial role in process optimization by providing accurate empirical data to verify and calibrate CFD simulation models, ensuring reliability in predicting fluid dynamics and heat transfer phenomena. It helps identify discrepancies between theoretical predictions and real-world behavior, allowing for model refinement and increased precision in optimizing operational parameters. Incorporating experimental results enhances the confidence in simulation-based decisions, leading to improved process efficiency and reduced development costs.

Comparative Analysis: CFD Predictions vs. Experimental Data

CFD simulation provides detailed flow field predictions, pressure distributions, and thermal characteristics, allowing for comprehensive analysis of complex fluid dynamics scenarios. Experimental validation offers empirical data through physical measurements such as velocity profiles, temperature fields, and turbulence intensities, serving as a benchmark to assess CFD model accuracy. Comparative analysis between CFD predictions and experimental data highlights discrepancies, calibrates turbulence models, and improves boundary condition settings, ultimately enhancing model reliability and predictive capability.

Integrating CFD and Experimental Approaches

Integrating CFD simulation with experimental validation enhances the accuracy and reliability of fluid dynamics studies by combining computational predictions with empirical data. This synergy allows for the identification of model limitations, calibration of turbulence parameters, and refinement of boundary conditions to better represent real-world scenarios. Leveraging both methods accelerates design optimization and reduces development cost by minimizing extensive physical prototyping.

Case Studies: Successful Validation of CFD Models

Case studies demonstrate that CFD simulation achieves high accuracy when validated through experimental data, enhancing reliability in fluid dynamics predictions. Examples include aerospace applications where wind tunnel results closely matched CFD predictions, confirming aerodynamic performance and design efficiency. Such validations solidify CFD's role in optimizing engineering processes by reducing costs and accelerating development cycles.

Future Trends in CFD Simulation and Experimental Validation

Future trends in CFD simulation and experimental validation emphasize integration of machine learning algorithms to enhance predictive accuracy and reduce computational costs. Innovations in high-fidelity experimental techniques, such as advanced particle image velocimetry (PIV) and real-time flow diagnostics, enable more precise data collection for validating complex simulations. The convergence of digital twins with CFD models promotes continuous validation and optimization in aerospace, automotive, and energy sectors, driving faster and more reliable design iterations.

Numerical accuracy

Numerical accuracy in CFD simulation is critical for predicting fluid dynamics precisely, often validated against experimental data to ensure reliability and reduce discrepancies in flow behavior analysis.

Model calibration

Model calibration in CFD simulation is essential to enhance accuracy by systematically adjusting parameters based on experimental validation data.

Boundary conditions

Accurate boundary condition specification in CFD simulation is critical for reliable correlation with experimental validation, as discrepancies in inlet velocity, temperature, or pressure profiles significantly impact predictive accuracy.

Mesh refinement

Mesh refinement significantly improves the accuracy of CFD simulation results, reducing discrepancies observed during experimental validation by better capturing flow details and gradients.

Turbulence modeling

Turbulence modeling in CFD simulation provides predictive flow dynamics that experimental validation accurately confirms by measuring real-world turbulence effects and discrepancies.

Experimental uncertainty

Experimental uncertainty in CFD simulation validation arises from measurement errors, sensor precision limits, and environmental variations, significantly impacting the accuracy and reliability of comparative analyses.

Validation metrics

Validation metrics such as Root Mean Square Error (RMSE), Mean Absolute Error (MAE), and coefficient of determination (R2) are crucial for quantifying the accuracy of CFD simulations against experimental data.

Scale-up correlation

CFD simulation scale-up correlation enhances experimental validation accuracy by enabling predictive modeling of complex fluid dynamics at industrial scales.

Data assimilation

Data assimilation integrates experimental validation with CFD simulation to enhance model accuracy by continuously updating computational predictions using real-time or historical experimental data.

Fluid-structure interaction

Fluid-structure interaction in CFD simulation provides detailed insights into dynamic responses and stress distributions, while experimental validation confirms accuracy by measuring physical deformation and flow-induced forces under real conditions.

CFD simulation vs experimental validation Infographic

njnir.com

njnir.com