Fluidized bed reactors offer superior heat and mass transfer due to the dynamic suspension of solid particles, enhancing reaction rates and uniform temperature distribution. In contrast, packed bed reactors provide a stable and simple design but often suffer from channeling and limited heat transfer efficiency. Choosing between these reactor types depends on process requirements, catalyst sensitivity, and operational flexibility.

Table of Comparison

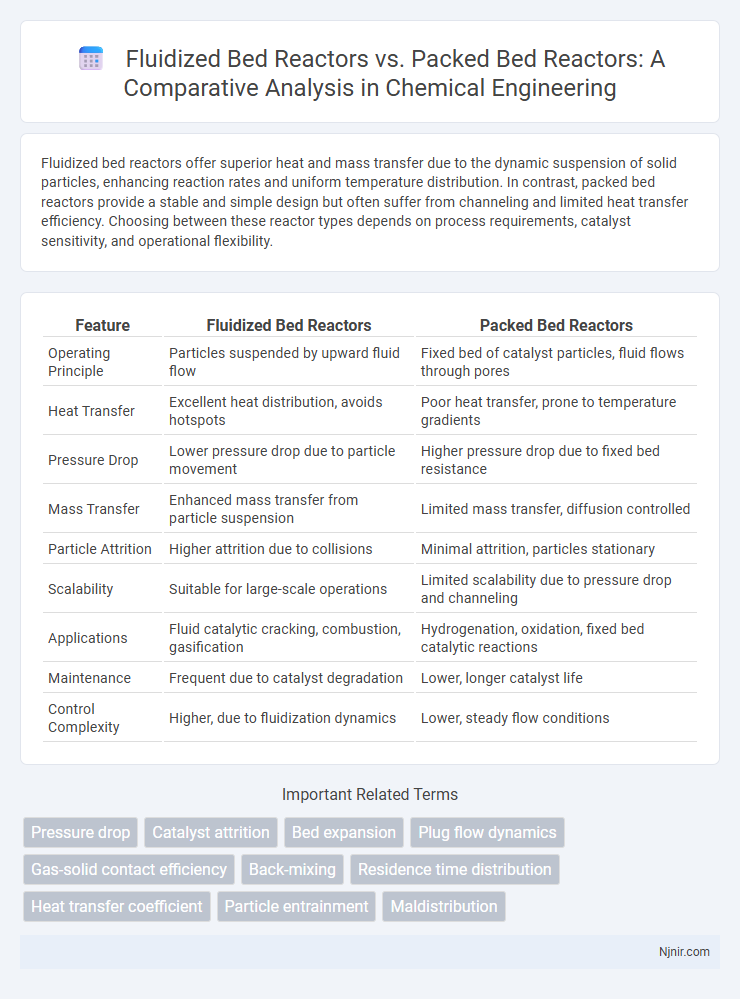

| Feature | Fluidized Bed Reactors | Packed Bed Reactors |

|---|---|---|

| Operating Principle | Particles suspended by upward fluid flow | Fixed bed of catalyst particles, fluid flows through pores |

| Heat Transfer | Excellent heat distribution, avoids hotspots | Poor heat transfer, prone to temperature gradients |

| Pressure Drop | Lower pressure drop due to particle movement | Higher pressure drop due to fixed bed resistance |

| Mass Transfer | Enhanced mass transfer from particle suspension | Limited mass transfer, diffusion controlled |

| Particle Attrition | Higher attrition due to collisions | Minimal attrition, particles stationary |

| Scalability | Suitable for large-scale operations | Limited scalability due to pressure drop and channeling |

| Applications | Fluid catalytic cracking, combustion, gasification | Hydrogenation, oxidation, fixed bed catalytic reactions |

| Maintenance | Frequent due to catalyst degradation | Lower, longer catalyst life |

| Control Complexity | Higher, due to fluidization dynamics | Lower, steady flow conditions |

Introduction to Fluidized Bed and Packed Bed Reactors

Fluidized bed reactors utilize a fluid to suspend solid catalyst particles, enhancing mass and heat transfer rates for improved reaction efficiency, especially in catalytic cracking and combustion processes. Packed bed reactors consist of a fixed arrangement of catalyst particles, offering simpler design and better suitability for reactions requiring precise contact time and temperature control, often used in hydrogenation and oxidation reactions. Understanding the operational dynamics and applications of both reactors aids in selecting the optimal system for chemical process intensification and scale-up.

Fundamental Operating Principles

Fluidized bed reactors operate by suspending solid catalyst particles in an upward flow of gas or liquid, creating a fluid-like state that enhances mass and heat transfer. Packed bed reactors consist of stationary catalyst-filled tubes or channels through which reactants flow, promoting plug flow behavior with limited mixing. The fluidization in fluidized bed reactors allows for better temperature control and uniform reactant distribution compared to the fixed catalyst bed in packed bed reactors.

Reactor Design and Configuration

Fluidized bed reactors feature a bed of solid particles suspended and mixed by an upward flow of fluid, enhancing heat and mass transfer with uniform temperature distribution and improved catalyst utilization. Packed bed reactors consist of a fixed bed of catalyst particles through which the fluid flows, offering simpler design but potentially facing channeling and temperature gradients. Design considerations prioritize fluidization velocity and particle size in fluidized beds, while packed beds emphasize pressure drop management and effective catalyst packing.

Heat and Mass Transfer Characteristics

Fluidized bed reactors exhibit superior heat and mass transfer characteristics due to the continuous movement and mixing of catalyst particles, resulting in enhanced thermal uniformity and reduced hot spots compared to packed bed reactors. In packed bed reactors, heat transfer is often limited by stagnant zones and poor fluid-solid contact, leading to temperature gradients that can affect reaction efficiency and selectivity. Fluidized beds also facilitate higher mass transfer rates through improved gas-solid interactions, making them ideal for highly exothermic reactions requiring rapid heat dissipation.

Advantages of Fluidized Bed Reactors

Fluidized bed reactors offer superior heat and mass transfer rates compared to packed bed reactors, enabling uniform temperature distribution and minimizing hotspots during chemical reactions. Their ability to handle feedstocks with varying particle sizes and high solids loading enhances operational flexibility and scalability in industrial processes. Enhanced mixing and continuous solids movement in fluidized beds also reduce catalyst deactivation and improve reaction efficiency, making them ideal for exothermic reactions and catalytic processes.

Advantages of Packed Bed Reactors

Packed bed reactors offer advantages such as high catalyst loading capacity and efficient contact between gas or liquid phases and solid catalysts, leading to improved reaction rates. Their fixed-bed design ensures easy operation, low pressure drop, and simplified catalyst replacement, making them suitable for continuous processes. Additionally, packed bed reactors provide excellent temperature control, minimizing hot spots and ensuring uniform reaction conditions for enhanced product quality.

Industrial Applications Comparison

Fluidized bed reactors excel in catalytic cracking, coal gasification, and biomass combustion due to superior heat and mass transfer, enabling efficient temperature control and uniform particle suspension. Packed bed reactors find extensive use in petrochemical synthesis, hydrogenation, and adsorption processes, offering high catalyst surface area and minimal fluid back-mixing but often face challenges with pressure drop and hotspot formation. Industrial applications select fluidized beds for handling large-scale, abrasive, or exothermic reactions requiring continuous solid movement, while packed beds suit processes demanding steady-state operations with well-defined flow paths.

Performance Efficiency and Scalability

Fluidized bed reactors demonstrate superior performance efficiency through enhanced mass and heat transfer, enabling uniform temperature distribution and improved reaction rates compared to packed bed reactors. Their scalability is advantageous for large-scale industrial applications, as fluidization maintains consistent particle suspension and mixing, reducing channeling and pressure drop issues common in packed beds. While packed bed reactors offer simplicity and lower capital costs, their limited scalability and susceptibility to catalyst deactivation hinder performance efficiency in extensive operations.

Common Challenges and Solutions

Fluidized bed reactors face challenges such as particle agglomeration and channeling, which reduce gas-solid contact efficiency, while packed bed reactors often suffer from pressure drop and hot spots due to uneven flow distribution. Solutions for fluidized beds include optimizing particle size distribution and using advanced distributor designs to enhance fluidization quality. For packed beds, implementing periodic backflushing and employing structured packing materials improve flow uniformity and thermal management.

Selection Criteria for Reactor Choice

Selection criteria for fluidized bed reactors versus packed bed reactors hinge on factors such as particle size, reaction type, and heat transfer requirements. Fluidized bed reactors excel in handling fine particles with excellent gas-solid contact and uniform temperature distribution, making them ideal for exothermic or highly endothermic reactions. Packed bed reactors are preferred for catalytic processes involving larger catalyst pellets, offering simpler design and lower pressure drop suitable for reactions requiring precise residence time control.

Pressure drop

Fluidized bed reactors exhibit significantly lower pressure drop compared to packed bed reactors due to their suspended particle flow regime, enhancing gas-solid contact and reducing energy consumption in high-throughput processes.

Catalyst attrition

Fluidized bed reactors exhibit higher catalyst attrition rates due to intense particle collisions and fluidization dynamics, whereas packed bed reactors maintain lower attrition by immobilizing catalyst particles within fixed packing structures.

Bed expansion

Fluidized bed reactors exhibit significant bed expansion due to particle suspension and fluidization velocity, enhancing mass transfer compared to the minimal bed expansion observed in packed bed reactors where particles remain static.

Plug flow dynamics

Fluidized bed reactors exhibit superior plug flow dynamics compared to packed bed reactors due to enhanced gas-solid mixing and reduced channeling effects.

Gas-solid contact efficiency

Fluidized bed reactors achieve higher gas-solid contact efficiency than packed bed reactors due to enhanced particle suspension and mixing, resulting in improved mass and heat transfer rates.

Back-mixing

Fluidized bed reactors exhibit significant back-mixing due to particle suspension, enhancing uniformity, whereas packed bed reactors have minimal back-mixing, promoting plug flow behavior.

Residence time distribution

Fluidized bed reactors exhibit narrower residence time distribution and enhanced mixing compared to packed bed reactors, leading to improved reaction uniformity and reduced channeling effects.

Heat transfer coefficient

Fluidized bed reactors typically exhibit higher heat transfer coefficients, ranging from 500 to 2000 W/m2*K, compared to packed bed reactors which usually have coefficients between 50 and 500 W/m2*K, resulting in more efficient thermal management and uniform temperature distribution in fluidized beds.

Particle entrainment

Fluidized bed reactors exhibit higher particle entrainment rates due to vigorous mixing and fluid velocity, whereas packed bed reactors maintain minimal entrainment with stable particle packing.

Maldistribution

Fluidized bed reactors minimize maldistribution by ensuring uniform particle suspension and enhanced mixing, whereas packed bed reactors often suffer from channeling and uneven flow distribution leading to maldistribution issues.

Fluidized bed reactors vs packed bed reactors Infographic

njnir.com

njnir.com