Fugitive emissions in chemical engineering refer to unintentional leaks or releases of gases or vapors from equipment such as valves, joints, and seals, which are often diffuse and harder to detect. Point-source emissions originate from specific, identifiable locations like stacks or vents and can be more easily monitored and controlled. Effective management of fugitive emissions requires advanced detection technologies and maintenance protocols, while point-source emissions benefit from regulatory permits and emission control devices.

Table of Comparison

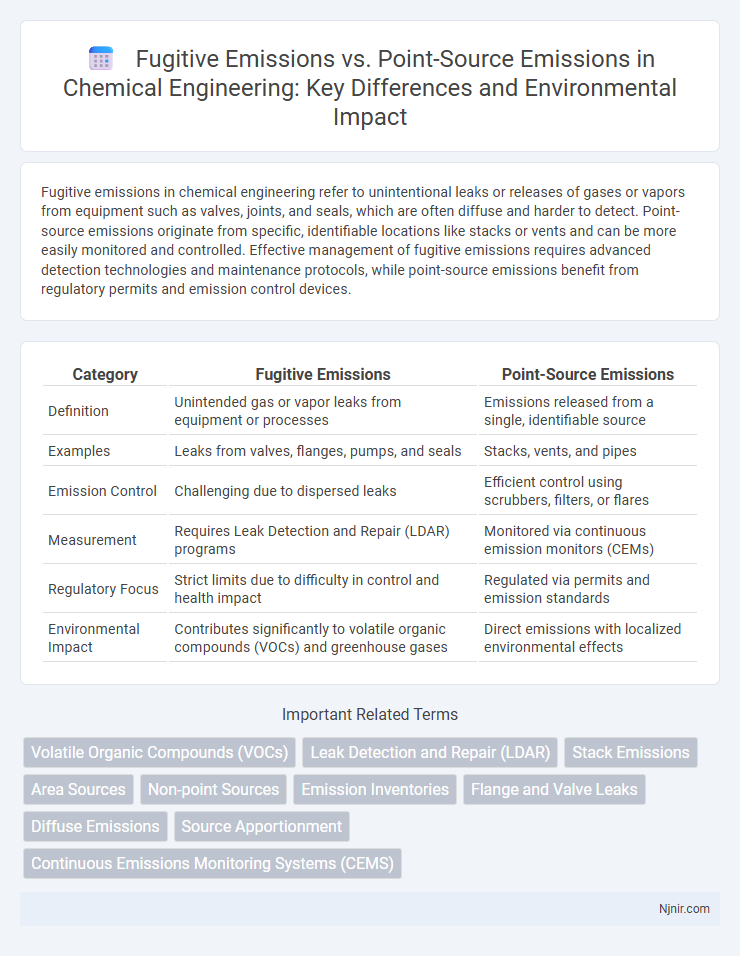

| Category | Fugitive Emissions | Point-Source Emissions |

|---|---|---|

| Definition | Unintended gas or vapor leaks from equipment or processes | Emissions released from a single, identifiable source |

| Examples | Leaks from valves, flanges, pumps, and seals | Stacks, vents, and pipes |

| Emission Control | Challenging due to dispersed leaks | Efficient control using scrubbers, filters, or flares |

| Measurement | Requires Leak Detection and Repair (LDAR) programs | Monitored via continuous emission monitors (CEMs) |

| Regulatory Focus | Strict limits due to difficulty in control and health impact | Regulated via permits and emission standards |

| Environmental Impact | Contributes significantly to volatile organic compounds (VOCs) and greenhouse gases | Direct emissions with localized environmental effects |

Introduction to Fugitive and Point-Source Emissions

Fugitive emissions refer to unintended gas leaks or vapors from pressurized equipment such as valves, connectors, and seals, often released into the atmosphere without passing through a stack, vent, or other confined air stream. Point-source emissions originate from identifiable, discrete sources like smokestacks, exhaust pipes, or industrial vents that release pollutants in a controlled manner. Understanding the differences between fugitive and point-source emissions is crucial for accurate environmental monitoring and regulatory compliance in industries such as oil and gas, manufacturing, and chemical production.

Defining Fugitive Emissions in Chemical Engineering

Fugitive emissions in chemical engineering refer to unintentional releases of gases or vapors from pressurized equipment due to leaks, equipment malfunctions, or operational errors, contrasting with point-source emissions that are controlled, identifiable, and released through defined outlets like stacks or vents. These emissions predominantly originate from valves, flanges, compressors, and storage tanks, posing significant environmental and safety risks by contributing to volatile organic compound (VOC) releases and greenhouse gases. Accurate detection and control of fugitive emissions are critical for regulatory compliance, minimizing industrial pollution, and improving process safety within chemical manufacturing facilities.

Understanding Point-Source Emissions in Industrial Processes

Point-source emissions refer to pollutants released from identifiable, confined locations such as smokestacks, vents, or pipes in industrial processes, allowing precise monitoring and control measures. These emissions typically consist of gases or particulate matter discharged during manufacturing, combustion, or chemical reactions, making them critical targets for regulatory compliance and pollution reduction strategies. Effective management of point-source emissions involves implementing technologies like scrubbers, filters, and continuous emission monitoring systems (CEMS) to minimize environmental impact and adhere to air quality standards.

Key Differences Between Fugitive and Point-Source Emissions

Fugitive emissions are unintended leaks or releases of gases from diffuse sources such as valves, pipelines, and equipment seals, whereas point-source emissions originate from specific, identifiable locations like smokestacks or exhaust vents. Key differences include measurement challenges, with fugitive emissions often harder to quantify due to their dispersed nature, while point-source emissions are easier to monitor and regulate. Regulatory frameworks and mitigation strategies also differ, focusing more on detection technologies for fugitive emissions and control technologies for point-source emissions.

Common Sources of Fugitive Emissions in Chemical Plants

Common sources of fugitive emissions in chemical plants include leaks from valves, pumps, flanges, and agitators, as well as faulty seals and connectors in equipment handling volatile chemicals. These emissions often escape from equipment seals or through cracks in piping and storage tanks, contributing significantly to hydrocarbon and volatile organic compound (VOC) releases. Regular monitoring and maintenance of these components are critical to minimizing the impact of fugitive emissions on air quality and regulatory compliance.

Primary Contributors to Point-Source Emissions

Point-source emissions primarily originate from identifiable and confined locations such as smokestacks, industrial vents, and exhaust pipes in factories and power plants. Major contributors include combustion processes in fossil fuel power generation, chemical manufacturing units, and metallurgical industries. Accurate monitoring and regulation at these fixed sites enable targeted emission control strategies, significantly reducing pollutants like sulfur dioxide, nitrogen oxides, and particulate matter.

Environmental Impacts of Fugitive vs. Point-Source Emissions

Fugitive emissions, which are unintentional leaks often from equipment or storage tanks, contribute significantly to air pollution and greenhouse gas accumulation, exacerbating climate change and posing health risks due to their diffuse nature that complicates detection and control. Point-source emissions, originating from identifiable, discrete sources like smokestacks or exhaust pipes, allow for more efficient monitoring and regulation but can result in concentrated pollution hotspots that severely impact local air quality and ecosystems. Addressing both emission types is critical for comprehensive environmental management strategies targeting reduced atmospheric pollutants and improved public health outcomes.

Detection and Monitoring Technologies for Emission Sources

Detection and monitoring technologies for fugitive emissions primarily utilize infrared cameras, ultrasonic detectors, and gas sniffers to identify leaks from non-point sources such as pipelines, valves, and storage tanks. Point-source emissions are monitored with fixed systems like continuous emission monitoring systems (CEMS) and stack gas analyzers that provide precise, real-time data from defined emission points such as smokestacks. Advanced remote sensing technologies, including drone-mounted sensors and satellite observation, enhance the ability to detect and quantify both fugitive and point-source emissions over large areas.

Mitigation Strategies for Emission Control

Mitigation strategies for fugitive emissions focus on leak detection and repair (LDAR) programs, using advanced sensor technologies like infrared cameras and ultrasonic detectors to pinpoint leaks in equipment and pipelines. Point-source emissions require targeted control measures such as scrubbers, filters, and catalytic converters installed directly on stacks or vents to capture pollutants before release. Implementing regular monitoring and maintenance protocols enhances emission control efficacy for both fugitive and point-source sources, reducing greenhouse gases and harmful pollutants effectively.

Regulatory Compliance and Reporting Requirements

Fugitive emissions, which are unintended leaks from equipment like valves and seals, pose significant challenges for regulatory compliance due to their diffuse nature and difficulty in detection, often requiring advanced monitoring technologies and detailed leak detection and repair (LDAR) programs. Point-source emissions, originating from identifiable locations such as smokestacks or vents, are more straightforward to measure and report under regulations like the U.S. EPA's Title V permit program, enabling precise emission quantification and easier compliance verification. Accurate reporting of both emission types is critical under frameworks such as the Greenhouse Gas Reporting Program (GHGRP) to ensure adherence to emission limits and to support transparent environmental impact assessments.

Volatile Organic Compounds (VOCs)

Fugitive emissions release Volatile Organic Compounds (VOCs) unintentionally from diffuse sources such as leaks and equipment malfunctions, whereas point-source emissions emit VOCs from identifiable, concentrated locations like stacks or vents.

Leak Detection and Repair (LDAR)

Leak Detection and Repair (LDAR) programs effectively reduce fugitive emissions by identifying and fixing leaks compared to controlling point-source emissions that are emitted from fixed, identifiable locations.

Stack Emissions

Stack emissions, a type of point-source emission, are released through identifiable, confined channels such as smokestacks, contrasting with fugitive emissions that escape from leaks or diffuse sources.

Area Sources

Fugitive emissions from area sources, such as leaks from equipment and open drains, contribute significantly to air pollution due to their diffuse and uncontained nature unlike concentrated point-source emissions.

Non-point Sources

Non-point source emissions, often overlooked compared to point-source emissions, originate from diffuse sources like agricultural runoff and urban stormwater, making them more challenging to monitor and control.

Emission Inventories

Fugitive emissions, often unintentional and diffuse leaks from equipment or processes, pose significant challenges for accurate emission inventories compared to point-source emissions, which are more easily monitored and quantified due to their identifiable and stationary nature.

Flange and Valve Leaks

Fugitive emissions from flange and valve leaks contribute significantly more greenhouse gases than point-source emissions due to their diffuse, unintentional release during industrial processes.

Diffuse Emissions

Diffuse emissions, a subset of fugitive emissions, occur as widespread, low-concentration releases from multiple, often inaccessible sources, contrasting sharply with the localized, high-intensity releases of point-source emissions.

Source Apportionment

Source apportionment techniques distinguish fugitive emissions, which escape from diffuse leaks or unintentional releases, from point-source emissions that originate from identifiable, fixed locations with measurable output.

Continuous Emissions Monitoring Systems (CEMS)

Continuous Emissions Monitoring Systems (CEMS) are primarily designed to track point-source emissions with high accuracy, while fugitive emissions require complementary detection technologies due to their diffuse and intermittent nature.

Fugitive emissions vs point-source emissions Infographic

njnir.com

njnir.com