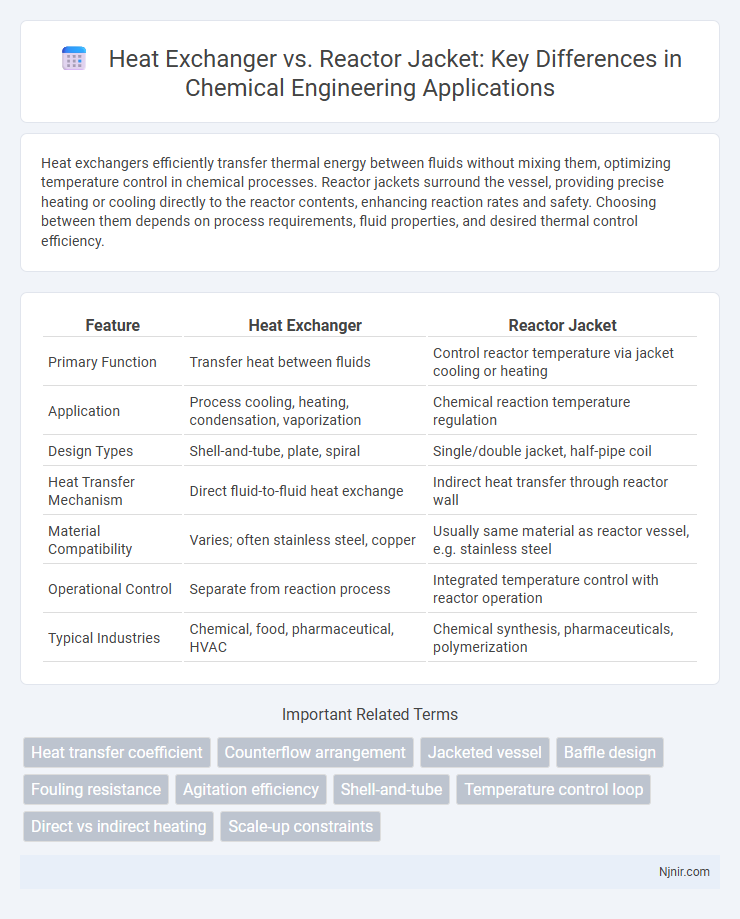

Heat exchangers efficiently transfer thermal energy between fluids without mixing them, optimizing temperature control in chemical processes. Reactor jackets surround the vessel, providing precise heating or cooling directly to the reactor contents, enhancing reaction rates and safety. Choosing between them depends on process requirements, fluid properties, and desired thermal control efficiency.

Table of Comparison

| Feature | Heat Exchanger | Reactor Jacket |

|---|---|---|

| Primary Function | Transfer heat between fluids | Control reactor temperature via jacket cooling or heating |

| Application | Process cooling, heating, condensation, vaporization | Chemical reaction temperature regulation |

| Design Types | Shell-and-tube, plate, spiral | Single/double jacket, half-pipe coil |

| Heat Transfer Mechanism | Direct fluid-to-fluid heat exchange | Indirect heat transfer through reactor wall |

| Material Compatibility | Varies; often stainless steel, copper | Usually same material as reactor vessel, e.g. stainless steel |

| Operational Control | Separate from reaction process | Integrated temperature control with reactor operation |

| Typical Industries | Chemical, food, pharmaceutical, HVAC | Chemical synthesis, pharmaceuticals, polymerization |

Introduction to Heat Exchangers and Reactor Jackets

Heat exchangers transfer thermal energy between fluids, optimizing heat transfer efficiency in industrial processes such as chemical manufacturing, power plants, and HVAC systems. Reactor jackets encase vessels to provide controlled heating or cooling, maintaining precise reaction temperatures in chemical reactors by circulating heat transfer fluids. Both systems are crucial for temperature regulation, with heat exchangers designed for efficient energy exchange and reactor jackets tailored for direct temperature control of reactor contents.

Fundamental Operating Principles

Heat exchangers operate by transferring thermal energy between fluids through a solid barrier, relying on conduction and convection to achieve efficient temperature control. Reactor jackets function by circulating heating or cooling fluids around the reactor vessel, providing precise temperature regulation for chemical reactions without directly mixing fluids. Both systems optimize thermal management but differ in their heat transfer mechanisms and applications within industrial processes.

Design and Structural Differences

Heat exchangers typically feature a compact design with multiple tubes or plates that facilitate efficient heat transfer between fluids, emphasizing maximum surface area and thermal conductivity. Reactor jackets, by contrast, are integral outer shells surrounding a reactor vessel, designed not only for heat transfer but also to accommodate thermal expansion and pressure variations, often incorporating insulation and ports for various heating or cooling media. Structurally, heat exchangers prioritize fluid dynamics and ease of cleaning, whereas reactor jackets focus on mechanical strength and integration with the reactor's process conditions.

Common Applications in Chemical Processes

Heat exchangers are widely used in chemical processes for transferring heat between fluids, often found in distillation columns, condensers, and cooling systems to regulate temperature and improve energy efficiency. Reactor jackets serve as integral temperature control units in chemical reactors, maintaining optimal reaction conditions by circulating heating or cooling fluids directly around the vessel. Both technologies are essential for processes such as polymerization, fermentation, and catalytic reactions where precise thermal management influences reaction rates and product quality.

Heat Transfer Mechanisms Comparison

Heat exchangers primarily rely on conduction and convection to transfer thermal energy efficiently between fluids, optimizing temperature control within industrial processes. Reactor jackets employ a similar heat transfer mechanism but integrate it directly into the reactor vessel, allowing precise temperature regulation vital for chemical reactions. The key difference lies in their design purpose: heat exchangers maximize surface area for heat exchange between separate streams, while reactor jackets enhance heat transfer around the reactor to maintain reaction conditions.

Efficiency and Performance Metrics

Heat exchangers exhibit high thermal efficiency by maximizing heat transfer surface area and facilitating precise temperature control, often measured by overall heat transfer coefficient (U-value) and effectiveness (e). Reactor jackets provide moderate heat transfer rates suitable for process safety and uniform temperature distribution; performance is typically assessed through temperature profiles, heat flux uniformity, and energy consumption metrics. Comparing both, heat exchangers outpace reactor jackets in heat transfer efficiency, while reactor jackets excel in operational reliability and process integration within chemical reactors.

Material Selection Criteria

Material selection for heat exchangers often prioritizes high thermal conductivity, corrosion resistance, and mechanical strength to ensure efficient heat transfer and durability under varying pressures and temperatures. Reactor jackets require materials that can withstand aggressive chemical environments, thermal cycling, and potential mechanical stresses while maintaining chemical inertness to prevent contamination or degradation. Common choices include stainless steel, titanium, and specialized alloys, selected based on compatibility with process fluids, temperature range, and corrosion resistance requirements.

Installation and Maintenance Considerations

Heat exchanger installation requires careful alignment and secure mounting to ensure efficient thermal transfer and prevent leaks, while reactor jackets demand precise fitting around the reactor vessel to maintain uniform temperature control. Maintenance of heat exchangers typically involves routine cleaning and inspection of tubes or plates to avoid fouling and corrosion, whereas reactor jackets require checking for cracks, corrosion, and proper sealing to prevent coolant leakage. Both systems prioritize accessibility, but reactor jackets often necessitate more specialized tools and procedures due to their integration with pressure vessels and chemical processes.

Cost Analysis and Economic Factors

Heat exchangers generally offer lower initial costs and simpler maintenance compared to reactor jackets, making them economically favorable for continuous heat transfer applications. Reactor jackets, while more expensive upfront due to complex fabrication and integration requirements, provide superior temperature control and energy efficiency, reducing long-term operating expenses. Cost analysis should account for lifespan, energy consumption, and process-specific heat transfer efficiency to determine the most economically viable choice.

Selection Guidelines for Chemical Engineers

Heat exchanger selection prioritizes efficient thermal transfer, material compatibility, and pressure drop constraints to optimize process heat management. Reactor jackets require focus on uniform heating or cooling, agitation effects, and ability to withstand operational conditions such as pressure and corrosion for safe, controlled reactions. Chemical engineers evaluate process temperature ranges, fluid properties, and maintenance ease to determine the optimal system balancing energy efficiency and operational reliability.

Heat transfer coefficient

Heat exchanger typically achieves higher heat transfer coefficients ranging from 500 to 10,000 W/m2*K compared to reactor jackets, which generally have coefficients between 50 and 500 W/m2*K due to differences in surface area and flow dynamics.

Counterflow arrangement

Counterflow heat exchangers maximize thermal efficiency by allowing fluids to flow in opposite directions, whereas reactor jackets provide uniform temperature control around the reactor vessel but typically use less efficient co-current flow designs.

Jacketed vessel

A jacketed vessel uses an external jacket to circulate heating or cooling fluids, providing precise temperature control in chemical reactors compared to traditional heat exchangers.

Baffle design

Baffle design in heat exchanger jackets optimizes fluid flow and heat transfer efficiency by promoting turbulence, whereas reactor jackets often use simpler or no baffles due to different mixing and temperature control requirements.

Fouling resistance

Reactor jackets typically exhibit lower fouling resistance compared to heat exchangers due to their simpler design and lower surface turbulence, which impacts cleaning frequency and maintenance efficiency.

Agitation efficiency

Reactor jackets provide less uniform heat transfer and lower agitation efficiency compared to integrated heat exchangers, which optimize temperature control and mixing performance for improved process outcomes.

Shell-and-tube

Shell-and-tube heat exchangers provide efficient thermal transfer in reactors by circulating coolant through the jacket, optimizing reaction temperature control and enhancing process safety.

Temperature control loop

Heat exchanger temperature control loops rapidly stabilize process temperatures by transferring heat between fluids, while reactor jacket temperature control loops precisely regulate reaction conditions by circulating heating or cooling media around the reactor vessel.

Direct vs indirect heating

Heat exchangers provide indirect heating by transferring heat through a barrier without fluid mixing, whereas reactor jackets enable direct heating by circulating a heating medium in direct contact with the reactor walls for efficient thermal control.

Scale-up constraints

Scale-up constraints for heat exchangers involve maintaining efficient heat transfer surface area and flow dynamics, while reactor jackets face challenges in uniform temperature control and mechanical stress distribution during scale-up.

Heat exchanger vs Reactor jacket Infographic

njnir.com

njnir.com