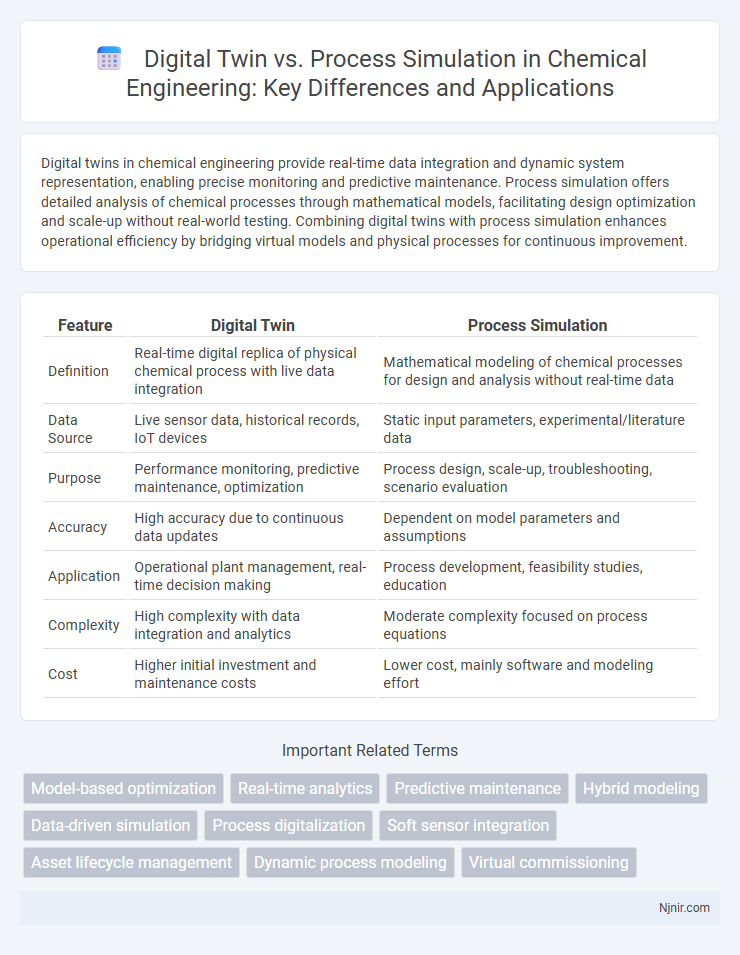

Digital twins in chemical engineering provide real-time data integration and dynamic system representation, enabling precise monitoring and predictive maintenance. Process simulation offers detailed analysis of chemical processes through mathematical models, facilitating design optimization and scale-up without real-world testing. Combining digital twins with process simulation enhances operational efficiency by bridging virtual models and physical processes for continuous improvement.

Table of Comparison

| Feature | Digital Twin | Process Simulation |

|---|---|---|

| Definition | Real-time digital replica of physical chemical process with live data integration | Mathematical modeling of chemical processes for design and analysis without real-time data |

| Data Source | Live sensor data, historical records, IoT devices | Static input parameters, experimental/literature data |

| Purpose | Performance monitoring, predictive maintenance, optimization | Process design, scale-up, troubleshooting, scenario evaluation |

| Accuracy | High accuracy due to continuous data updates | Dependent on model parameters and assumptions |

| Application | Operational plant management, real-time decision making | Process development, feasibility studies, education |

| Complexity | High complexity with data integration and analytics | Moderate complexity focused on process equations |

| Cost | Higher initial investment and maintenance costs | Lower cost, mainly software and modeling effort |

Introduction to Digital Twin and Process Simulation

Digital twin technology creates a dynamic, real-time digital replica of physical assets or processes, enabling continuous monitoring and predictive analysis through sensor integration and data analytics. Process simulation involves constructing mathematical models to replicate and analyze the behavior of manufacturing or operational processes, often used for optimization and scenario testing. While process simulation provides insights based on static or hypothetical data, digital twins offer real-time feedback, bridging the gap between virtual models and actual performance for enhanced decision-making.

Core Principles: Digital Twin Explained

Digital twin technology creates an exact virtual replica of physical assets, processes, or systems, continuously updated with real-time data to mirror actual performance and conditions. Process simulation models the behavior of systems under various scenarios, primarily using static or historical data to predict outcomes without real-time synchronization. The core principle of digital twins lies in their dynamic, data-driven nature, enabling predictive maintenance, operational optimization, and enhanced decision-making through seamless integration with IoT sensors and live feedback loops.

Fundamentals of Process Simulation

Process simulation involves creating a virtual model of chemical, physical, or mechanical processes to predict performance and optimize operations using mathematical equations and reaction kinetics. Unlike digital twins that integrate real-time data for dynamic monitoring, process simulation focuses on steady-state or transient analysis based on theoretical models and predefined parameters. Key fundamentals include mass and energy balances, thermodynamics, reaction mechanisms, and transport phenomena to accurately replicate process behavior and guide design decisions.

Key Differences Between Digital Twin and Process Simulation

Digital twin technology provides a real-time, dynamic representation of physical assets or processes by continuously integrating data from sensors, enabling predictive maintenance and operational optimization. Process simulation models, on the other hand, create static or scenario-based representations of processes, often used for design, analysis, and optimization before implementation. Key differences lie in real-time data integration, continuous synchronization with the physical system in digital twins, versus the offline, discrete scenario analysis characteristic of process simulation tools.

Applications in Chemical Engineering

Digital twin technology in chemical engineering enables real-time monitoring and optimization of plant operations by integrating sensor data with predictive models, enhancing process efficiency and fault detection. Process simulation focuses on designing and analyzing chemical processes through computational models to test scenarios, scale-up operations, and evaluate process parameters before implementation. Combining digital twins with process simulation accelerates innovation in chemical plants by providing dynamic, data-driven insights and virtual process validation.

Real-Time Data Integration and Analytics

Digital twin technology outperforms traditional process simulation by integrating real-time data from IoT sensors and operational systems, enabling dynamic modeling of assets and processes. This continuous data flow allows for precise analytics and predictive insights, driving proactive decision-making and operational optimization. Process simulation typically relies on static models and historical data, limiting its ability to adapt instantly to changing conditions.

Enhanced Process Optimization: Digital Twin vs Simulation

Digital twins provide real-time, dynamic data integration enabling continuous process optimization, whereas process simulations rely on static models for predictive analysis. Digital twins deliver enhanced decision-making by reflecting actual operational conditions and enabling immediate adjustments. This continuous feedback loop makes digital twins superior in optimizing complex industrial processes compared to traditional process simulation.

Challenges and Limitations

Digital twin technology faces challenges in real-time data integration and maintaining accurate synchronization with physical assets, limiting its effectiveness in dynamic environments. Process simulation often struggles with model accuracy due to assumptions and simplifications, which can result in less reliable predictions. Both approaches encounter scalability issues and high computational demands that restrict their application in complex industrial systems.

Future Trends in Chemical Process Modeling

Digital twins in chemical process modeling leverage real-time data integration and advanced analytics to create dynamic, adaptive representations of physical systems, surpassing traditional process simulation's static and predictive capabilities. Future trends emphasize the convergence of machine learning, Internet of Things (IoT) connectivity, and cloud computing to enhance the accuracy, scalability, and operational insight of digital twins. These advancements enable proactive process optimization, predictive maintenance, and accelerated innovation cycles, driving greater efficiency and sustainability in chemical manufacturing.

Selecting the Right Approach for Your Plant

Digital twin technology offers real-time, data-driven insights by creating a dynamic replica of your plant, enabling predictive maintenance and operational optimization. Process simulation focuses on modeling specific workflows or chemical processes to evaluate design changes and performance under various scenarios without real-time data integration. Selecting the right approach depends on your plant's needs for real-time monitoring, data availability, and the level of process complexity you aim to analyze or optimize.

Model-based optimization

Digital twin technology enables real-time, model-based optimization by continuously integrating physical process data, whereas traditional process simulation relies on static models for predictive analysis and scenario testing.

Real-time analytics

Digital twins enable real-time analytics by continuously synchronizing with physical assets, offering dynamic, live data insights superior to traditional process simulations that rely on static, pre-defined models.

Predictive maintenance

Digital twin technology enables real-time predictive maintenance by continuously monitoring equipment through sensor data integration, while process simulation primarily predicts maintenance needs based on static modeling without real-time updates.

Hybrid modeling

Hybrid modeling integrates digital twins and process simulation by combining real-time sensor data with predictive algorithms to enhance accuracy and operational efficiency in industrial applications.

Data-driven simulation

Data-driven digital twins leverage real-time sensor data and machine learning to create dynamic, accurate models, whereas traditional process simulations rely on static mathematical models with predefined parameters.

Process digitalization

Digital twins enable real-time data integration and dynamic process optimization, surpassing traditional process simulations by offering comprehensive process digitalization for enhanced operational efficiency.

Soft sensor integration

Digital twin technology integrates soft sensors to continuously monitor and predict real-time process performance, offering enhanced accuracy and adaptability compared to traditional process simulation models.

Asset lifecycle management

Digital twins provide real-time, data-driven visualization and predictive analytics for asset lifecycle management, whereas process simulation primarily offers scenario-based modeling and optimization during design and planning phases.

Dynamic process modeling

Digital twins provide real-time dynamic process modeling by integrating live data for continuous system optimization, whereas traditional process simulation relies on static or predefined scenarios without real-time updates.

Virtual commissioning

Digital twin technology enhances virtual commissioning by providing real-time, dynamic replication of physical assets, whereas process simulation primarily models static system behaviors without live data integration.

Digital twin vs process simulation Infographic

njnir.com

njnir.com