Biorefineries utilize renewable biomass feedstocks to produce fuels, chemicals, and materials, promoting sustainability and reducing carbon emissions. Petrorefineries rely on fossil fuels, contributing to environmental pollution and resource depletion. Advances in biorefinery technologies enhance energy efficiency and product diversification, positioning them as a key component in the transition to a circular bioeconomy.

Table of Comparison

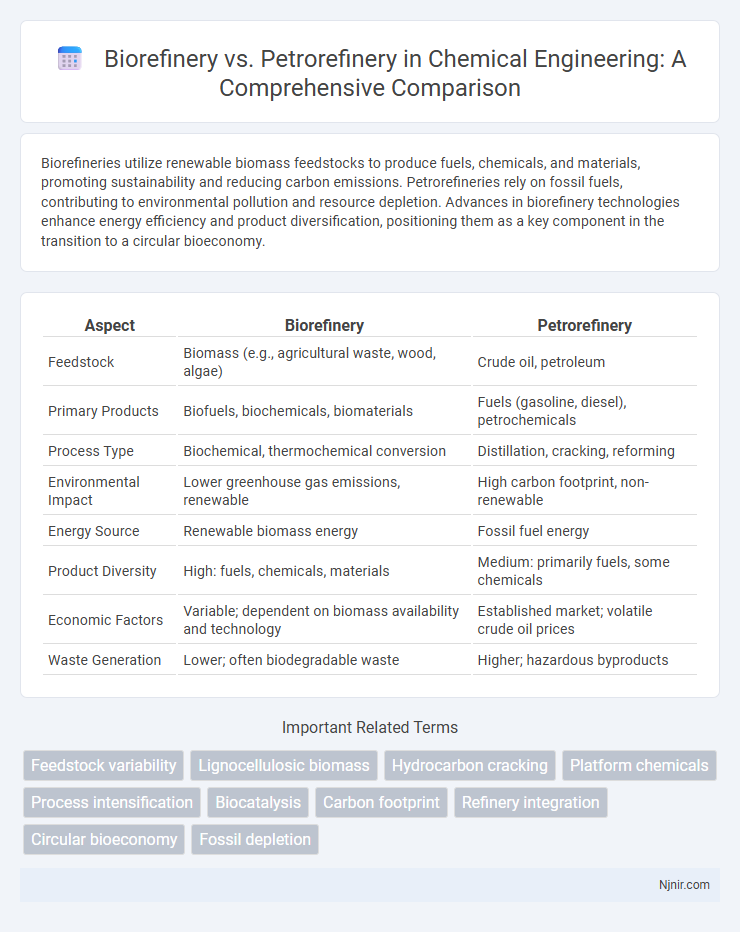

| Aspect | Biorefinery | Petrorefinery |

|---|---|---|

| Feedstock | Biomass (e.g., agricultural waste, wood, algae) | Crude oil, petroleum |

| Primary Products | Biofuels, biochemicals, biomaterials | Fuels (gasoline, diesel), petrochemicals |

| Process Type | Biochemical, thermochemical conversion | Distillation, cracking, reforming |

| Environmental Impact | Lower greenhouse gas emissions, renewable | High carbon footprint, non-renewable |

| Energy Source | Renewable biomass energy | Fossil fuel energy |

| Product Diversity | High: fuels, chemicals, materials | Medium: primarily fuels, some chemicals |

| Economic Factors | Variable; dependent on biomass availability and technology | Established market; volatile crude oil prices |

| Waste Generation | Lower; often biodegradable waste | Higher; hazardous byproducts |

Introduction to Biorefinery and Petrorefinery

Biorefineries convert biomass such as agricultural residues and organic waste into biofuels, biochemicals, and bioenergy using sustainable and renewable processes. Petrorefineries process crude oil through distillation and chemical treatments to produce fuels, lubricants, and petrochemicals, relying on finite fossil resources. The shift towards biorefineries supports reduced carbon emissions and resource sustainability compared to traditional petrorefinery operations.

Historical Evolution of Refinery Technologies

Biorefinery technologies evolved from traditional petrorefinery processes by integrating biomass conversion methods to produce biofuels, biochemicals, and biomaterials, reflecting a shift toward sustainable energy sources that began gaining momentum in the late 20th century. Petrorefineries, established during the late 19th and early 20th centuries, initially focused on crude oil distillation, advancing through catalytic cracking and hydroprocessing techniques to maximize liquid fuel yields. The historical evolution highlights how biorefineries incorporate biological feedstocks and green chemistry principles, contrasting with the petroleum-centric infrastructure that dominated industrial energy production for over a century.

Feedstock Comparison: Biomass vs. Fossil Fuels

Biorefineries utilize biomass feedstocks such as agricultural residues, forestry waste, and dedicated energy crops, providing renewable and carbon-neutral sources for producing biofuels, biochemicals, and bio-based materials. Petrorefineries rely on fossil fuels like crude oil and natural gas, which are finite, carbon-intensive, and contribute significantly to greenhouse gas emissions. The shift from fossil fuels to biomass feedstocks in biorefineries supports sustainability goals and reduces dependence on non-renewable resources.

Process Flow Differences in Biorefineries and Petrorefineries

Biorefineries utilize biomass feedstocks through processes such as fermentation, enzymatic hydrolysis, and thermochemical conversion to produce biofuels, biochemicals, and bio-based materials, emphasizing renewable resource utilization. Petrorefineries process crude oil using distillation, catalytic cracking, and reforming to generate fuels and petrochemical products, focusing on fossil resources. The process flow in biorefineries integrates biochemical and thermochemical pathways with pretreatment steps to handle heterogeneous biomass, while petrorefineries primarily rely on uniform hydrocarbon fractionation and catalytic upgrading techniques.

Product Spectrum: Fuels, Chemicals, and By-products

Biorefineries produce a diverse range of bio-based fuels such as ethanol, biodiesel, and biogas, alongside renewable chemicals like bioplastics and organic acids, with valuable by-products including lignin and biochar used for energy or soil enhancement. Petrorefineries primarily generate fossil fuel-based products including gasoline, diesel, jet fuel, and petrochemicals like ethylene and propylene, with by-products such as petroleum coke and sulfur. The product spectrum of biorefineries emphasizes sustainability and carbon neutrality, whereas petrorefineries focus on maximizing energy content and petrochemical feedstock yield.

Environmental Impact and Sustainability Assessment

Biorefineries utilize renewable biomass feedstocks to produce biofuels, biochemicals, and biomaterials, significantly reducing greenhouse gas emissions compared to petrorefineries, which rely on fossil fuels and contribute to air and water pollution. Life cycle assessments reveal that biorefineries offer enhanced sustainability by promoting carbon neutrality, decreasing reliance on finite resources, and enabling waste valorization, whereas petrorefineries propagate environmental degradation and resource depletion. Sustainable biorefinery practices support circular economy principles by integrating energy-efficient technologies and minimizing ecological footprints, presenting a viable pathway for reducing global environmental impact.

Energy Efficiency and Resource Utilization

Biorefineries convert biomass into biofuels, biochemicals, and energy with higher energy efficiency by utilizing renewable feedstocks and integrating waste valorization processes. Petrorefineries rely on fossil fuels, often exhibiting lower energy efficiency due to the energy-intensive refining of crude oil and limited by finite resource availability. Biorefineries optimize resource utilization by employing sustainable raw materials and circular economy principles, reducing environmental impact compared to the traditional petrorefinery model.

Technological Challenges and Innovations

Biorefineries face technological challenges in efficiently converting diverse biomass feedstocks into fuels, chemicals, and materials, requiring advanced pretreatment methods, enzyme optimization, and microbial engineering to enhance yield and reduce costs. Innovations in catalysis, process integration, and bioprocessing technologies drive improvements in biomass conversion efficiency and product selectivity, addressing scalability and sustainability concerns. Petrorefineries rely on well-established catalytic cracking, distillation, and hydroprocessing technologies but face pressure to innovate with carbon capture and integration of bio-based co-feedstocks to reduce greenhouse gas emissions.

Economic Viability and Market Trends

Biorefineries leverage renewable biomass feedstocks, offering economic viability through reduced dependency on volatile fossil fuel markets and government incentives for sustainable practices, while petrorefineries remain dominant due to established infrastructure and lower initial capital costs. Market trends show increasing investment and growth in biorefinery technologies driven by rising demand for bio-based products, carbon reduction goals, and advancements in conversion processes that enhance yield and efficiency. Economic viability hinges on feedstock availability, scale of operation, and policy frameworks that influence competitiveness between biorefineries and petrorefineries in global energy markets.

Future Prospects and Industry Outlook

Biorefineries are poised for significant growth as global demand shifts towards sustainable and renewable energy sources, with projections indicating a compound annual growth rate (CAGR) exceeding 12% over the next decade. Petrorefineries face increasing regulatory pressures and market volatility due to fluctuating crude oil prices and carbon emission targets, pushing the industry towards integrating bio-based feedstocks and hybrid processing technologies. Investment trends and policy frameworks, such as the European Green Deal and the U.S. Renewable Fuel Standard, drive innovation and expansion in biorefinery capabilities, promoting a transition to a circular bioeconomy and enhanced carbon neutrality.

Feedstock variability

Biorefineries utilize diverse and renewable biomass feedstocks with high variability in composition, while petrorefineries rely on relatively uniform fossil fuel feedstocks such as crude oil.

Lignocellulosic biomass

Biorefineries convert lignocellulosic biomass into biofuels, biochemicals, and biomaterials using sustainable processes, whereas petrorefineries rely on crude oil to produce fuels and chemicals with higher carbon emissions and environmental impact.

Hydrocarbon cracking

Hydrocarbon cracking in biorefineries utilizes biomass-derived feedstocks to produce renewable fuels and chemicals, whereas petrorefineries rely on fossil-based hydrocarbons to generate conventional petroleum products through thermal and catalytic cracking processes.

Platform chemicals

Biorefineries produce platform chemicals like bio-based ethanol, lactic acid, and succinic acid derived from renewable biomass, whereas petrorefineries generate platform chemicals such as ethylene, propylene, and benzene from fossil fuels.

Process intensification

Process intensification in biorefineries enhances biomass conversion efficiency and sustainability by integrating advanced catalytic, enzymatic, and separation techniques, whereas petrorefineries focus on optimizing hydrocarbon cracking and distillation processes to maximize fuel yield.

Biocatalysis

Biocatalysis in biorefineries enhances sustainable chemical production by using enzymes and microorganisms to convert biomass into biofuels and biochemicals, contrasting with petrorefineries that rely on fossil fuel processing.

Carbon footprint

Biorefineries significantly reduce carbon footprint by converting biomass into renewable fuels and chemicals, whereas petrorefineries rely on fossil fuels, resulting in higher greenhouse gas emissions.

Refinery integration

Biorefinery integration prioritizes sustainable processing of biomass into multiple bio-based products and fuels, while petrorefinery integration focuses on optimizing the conversion of crude oil into a broad range of petroleum-derived products through established refining processes.

Circular bioeconomy

Biorefineries convert biomass into bio-based products and fuels, promoting circular bioeconomy by utilizing renewable resources and reducing carbon emissions compared to conventional petrorefineries reliant on fossil fuels.

Fossil depletion

Biorefineries reduce fossil fuel depletion by converting renewable biomass into energy and chemicals, whereas petrorefineries rely on finite fossil resources, accelerating their depletion.

Biorefinery vs Petrorefinery Infographic

njnir.com

njnir.com