Flow chemistry offers continuous processing with enhanced reaction control, leading to improved safety, scalability, and product consistency compared to traditional batch chemistry. The precise regulation of temperature and reactant mixing in flow systems minimizes side reactions and waste generation. This approach accelerates reaction kinetics and facilitates real-time monitoring, making it ideal for high-throughput chemical synthesis and industrial applications.

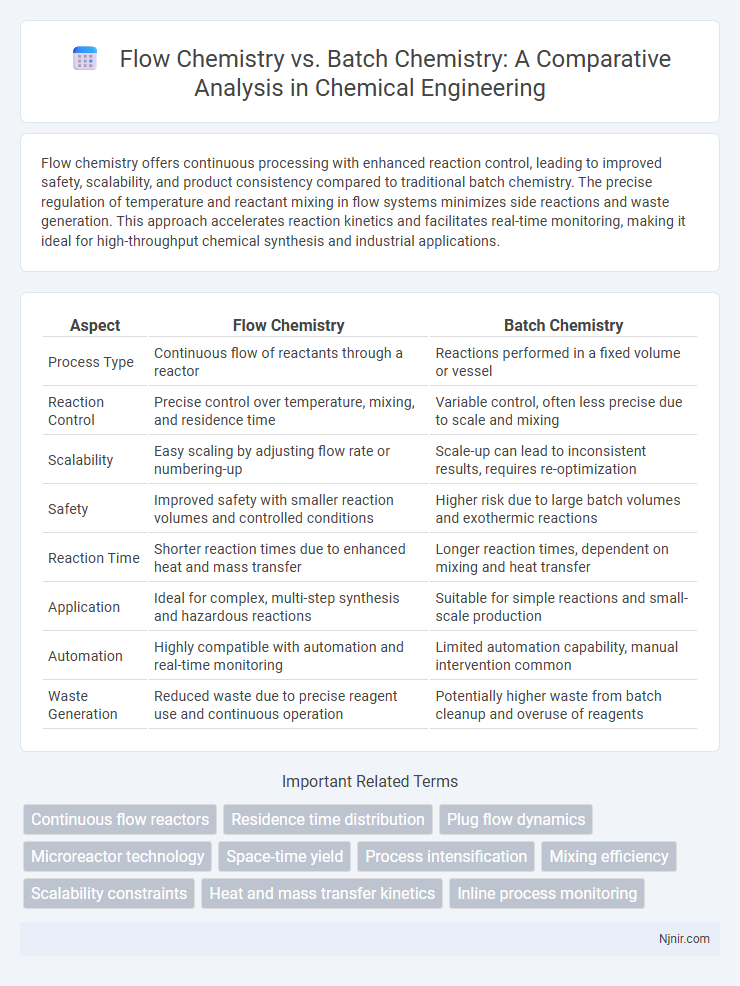

Table of Comparison

| Aspect | Flow Chemistry | Batch Chemistry |

|---|---|---|

| Process Type | Continuous flow of reactants through a reactor | Reactions performed in a fixed volume or vessel |

| Reaction Control | Precise control over temperature, mixing, and residence time | Variable control, often less precise due to scale and mixing |

| Scalability | Easy scaling by adjusting flow rate or numbering-up | Scale-up can lead to inconsistent results, requires re-optimization |

| Safety | Improved safety with smaller reaction volumes and controlled conditions | Higher risk due to large batch volumes and exothermic reactions |

| Reaction Time | Shorter reaction times due to enhanced heat and mass transfer | Longer reaction times, dependent on mixing and heat transfer |

| Application | Ideal for complex, multi-step synthesis and hazardous reactions | Suitable for simple reactions and small-scale production |

| Automation | Highly compatible with automation and real-time monitoring | Limited automation capability, manual intervention common |

| Waste Generation | Reduced waste due to precise reagent use and continuous operation | Potentially higher waste from batch cleanup and overuse of reagents |

Introduction to Flow Chemistry and Batch Chemistry

Flow chemistry enables continuous reagent flow through reactors, offering enhanced reaction control, improved heat and mass transfer, and scalability compared to batch chemistry, where reactions occur in fixed volumes within vessels. Batch chemistry allows flexibility for small-scale synthesis and simple setups but often faces challenges with reproducibility and scale-up due to limitations in mixing and temperature control. Flow systems provide better reaction efficiency and safety, making them increasingly preferred for pharmaceutical and fine chemical manufacturing.

Key Principles of Flow Chemistry

Flow chemistry operates on the principle of continuous reagent flow through a reactor, enabling precise control over reaction time, temperature, and mixing, which contrasts with the static conditions of batch chemistry. It leverages microreactors or tubular reactors to enhance heat and mass transfer, minimize reaction times, and improve safety by reducing the handling of hazardous materials. This technique allows for scalable, reproducible syntheses with higher efficiency and selectivity compared to traditional batch processes.

Fundamental Aspects of Batch Chemistry

Batch chemistry involves conducting chemical reactions in a single, contained vessel where all reactants are combined and processed over a set time period. Reaction conditions such as temperature, pressure, and mixing intensity are controlled but can vary throughout the vessel, potentially leading to concentration gradients and inconsistent product yield. This approach is well-suited for small-scale syntheses and complex multistep reactions requiring precise intervention at specific stages.

Comparative Analysis: Process Efficiency

Flow chemistry offers superior process efficiency compared to batch chemistry by enabling continuous product formation, precise control over reaction parameters, and enhanced heat and mass transfer. This results in higher reaction rates, improved yield consistency, and reduced reaction times, minimizing downtime between batches. Batch chemistry often suffers from scale-up challenges and slower heat dissipation, which can limit reaction efficiency and reproducibility.

Safety Considerations in Flow vs Batch Processes

Flow chemistry offers enhanced safety by minimizing the volume of hazardous reagents at any given time, reducing the risk of large-scale accidents common in batch processes. Continuous flow systems allow precise control over reaction conditions such as temperature and pressure, preventing runaway reactions and improving heat dissipation. In contrast, batch chemistry often involves handling larger quantities of reactive substances simultaneously, increasing potential exposure to toxic chemicals and making containment of emergency incidents more challenging.

Scalability and Production Throughput

Flow chemistry offers superior scalability by enabling continuous processing, which significantly increases production throughput compared to traditional batch chemistry that relies on discrete, time-consuming reaction cycles. The consistent reaction environment in flow chemistry improves reaction control and reproducibility, facilitating seamless scale-up from lab to industrial production without compromising product quality. Batch chemistry, although flexible for small-scale synthesis, often faces limitations in scalability and slower throughput due to the need for repeated setup and cleanup between batches.

Reaction Control and Optimization

Flow chemistry offers superior reaction control through continuous monitoring of parameters like temperature, pressure, and residence time, enabling precise optimization of reaction conditions. Batch chemistry often faces limitations in scalability and reproducibility due to less consistent mixing and heat transfer, leading to variability in reaction outcomes. Enhanced control in flow systems allows for rapid adjustments and improved selectivity, resulting in higher efficiency and safer reaction processes.

Sustainability and Waste Reduction

Flow chemistry enhances sustainability by enabling precise control over reaction conditions, which minimizes reagent excess and energy consumption compared to traditional batch chemistry. Continuous processing in flow systems significantly reduces chemical waste and solvent usage due to improved reaction efficiency and scalability. This approach supports greener manufacturing practices by lowering the environmental footprint and facilitating safer, more cost-effective production cycles.

Industrial Applications and Case Studies

Flow chemistry offers superior heat and mass transfer control, enabling continuous production with higher efficiency and scalability in pharmaceutical and fine chemical industries. Industrial applications demonstrate significant reductions in reaction times and waste generation compared to traditional batch chemistry, as seen in large-scale synthesis of active pharmaceutical ingredients (APIs) by companies like Pfizer and Eli Lilly. Case studies highlight enhanced safety and consistent product quality in flow reactors, making them ideal for hazardous reactions and multi-step processes in chemical manufacturing.

Future Trends in Chemical Process Engineering

Flow chemistry offers enhanced scalability, precise reaction control, and improved safety, positioning it as a key technology for future chemical process engineering advancements. Integration of continuous flow systems with automation, real-time analytics, and machine learning algorithms is expected to accelerate process optimization and reduce production costs. Emerging trends emphasize sustainable manufacturing through energy-efficient reactors and minimized waste generation, driving the transition from traditional batch processes to innovative continuous flow platforms.

Continuous flow reactors

Continuous flow reactors in flow chemistry offer enhanced heat transfer, precise reaction control, and scalable production compared to traditional batch chemistry methods.

Residence time distribution

Flow chemistry provides precise control over residence time distribution, enhancing reaction consistency and scalability compared to the broad and variable residence time distribution in batch chemistry.

Plug flow dynamics

Flow chemistry utilizing plug flow dynamics ensures uniform reactant residence time and enhanced heat transfer compared to batch chemistry, optimizing reaction efficiency and selectivity.

Microreactor technology

Microreactor technology in flow chemistry enhances reaction control, safety, and efficiency compared to traditional batch chemistry by enabling precise temperature management and rapid mixing at microscale volumes.

Space-time yield

Flow chemistry achieves significantly higher space-time yield than batch chemistry by enabling continuous reactant processing, precise reaction control, and improved heat and mass transfer.

Process intensification

Flow chemistry enhances process intensification by enabling continuous, controlled reactions with improved heat and mass transfer compared to traditional batch chemistry.

Mixing efficiency

Flow chemistry enhances mixing efficiency by enabling continuous, controlled reactant introduction and rapid, uniform reagent diffusion, outperforming traditional batch chemistry where mixing is often slower and less homogeneous.

Scalability constraints

Flow chemistry offers superior scalability with continuous processing and precise control over reaction parameters, while batch chemistry faces limitations due to reactor size, heat transfer inefficiencies, and inconsistent reaction conditions during scale-up.

Heat and mass transfer kinetics

Flow chemistry enhances heat and mass transfer kinetics through continuous mixing and precise temperature control, outperforming batch chemistry's slower and less uniform transfer processes.

Inline process monitoring

Flow chemistry enables real-time inline process monitoring with enhanced control and rapid reaction optimization compared to traditional batch chemistry methods.

Flow chemistry vs Batch chemistry Infographic

njnir.com

njnir.com