Solid Phase Peptide Synthesis (SPPS) offers faster peptide assembly and easier purification compared to Liquid Phase Peptide Synthesis (LPPS), making it ideal for synthesizing short to medium-length peptides. LPPS, while more labor-intensive and time-consuming, allows greater control over reaction conditions and is beneficial for producing longer peptides with higher purity. Optimization of coupling efficiency and protecting group strategies is critical in both methods to achieve high yields and minimize by-products in peptide production.

Table of Comparison

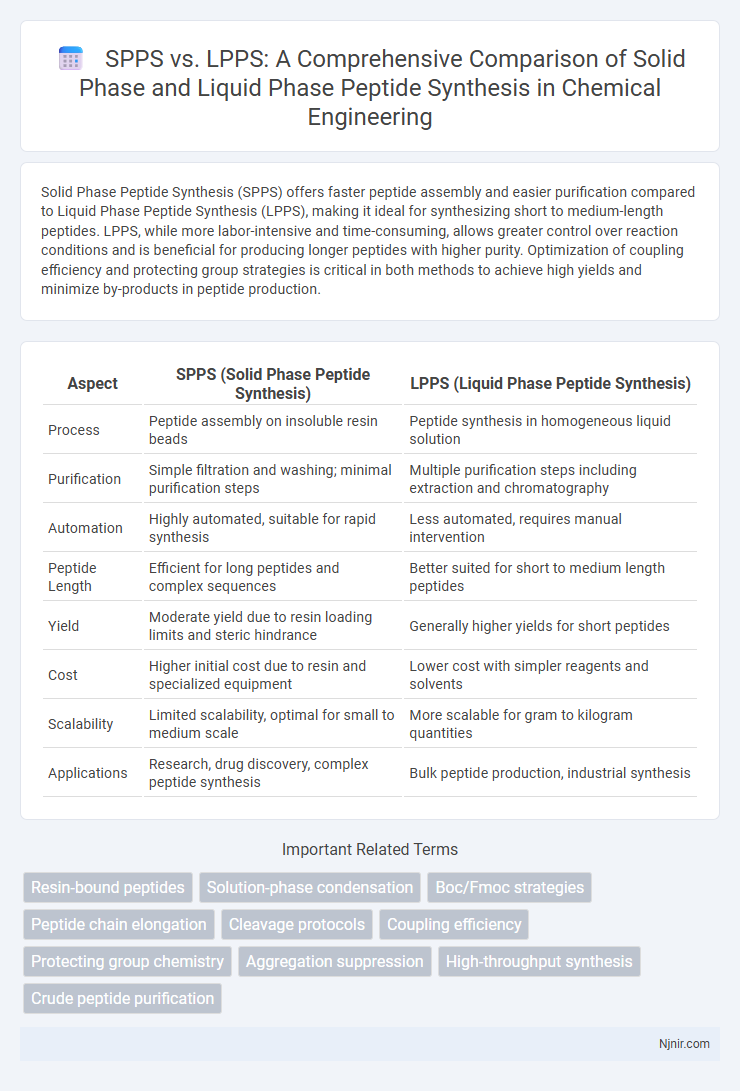

| Aspect | SPPS (Solid Phase Peptide Synthesis) | LPPS (Liquid Phase Peptide Synthesis) |

|---|---|---|

| Process | Peptide assembly on insoluble resin beads | Peptide synthesis in homogeneous liquid solution |

| Purification | Simple filtration and washing; minimal purification steps | Multiple purification steps including extraction and chromatography |

| Automation | Highly automated, suitable for rapid synthesis | Less automated, requires manual intervention |

| Peptide Length | Efficient for long peptides and complex sequences | Better suited for short to medium length peptides |

| Yield | Moderate yield due to resin loading limits and steric hindrance | Generally higher yields for short peptides |

| Cost | Higher initial cost due to resin and specialized equipment | Lower cost with simpler reagents and solvents |

| Scalability | Limited scalability, optimal for small to medium scale | More scalable for gram to kilogram quantities |

| Applications | Research, drug discovery, complex peptide synthesis | Bulk peptide production, industrial synthesis |

Introduction to Peptide Synthesis Techniques

Solid Phase Peptide Synthesis (SPPS) offers efficient automation and rapid assembly of peptide chains anchored on a solid resin, enabling straightforward purification by filtration. Liquid Phase Peptide Synthesis (LPPS) involves peptide elongation in solution, providing precise control over reaction conditions and suitability for synthesizing peptides with complex modifications. Both techniques are fundamental in peptide engineering, with SPPS favored for high-throughput production and LPPS for specific, high-purity peptide sequences.

Fundamentals of Solid Phase Peptide Synthesis (SPPS)

Solid Phase Peptide Synthesis (SPPS) involves sequentially adding protected amino acids to a solid resin support, facilitating easy removal of excess reagents through filtration after each coupling step. This method enhances peptide chain assembly efficiency by minimizing purification between steps and enables automation, significantly accelerating peptide synthesis. SPPS is fundamental for producing complex peptides with high purity and yield, distinguishing it from Liquid Phase Peptide Synthesis (LPPS), which requires more extensive purification due to reactions occurring in solution.

Principles of Liquid Phase Peptide Synthesis (LPPS)

Liquid Phase Peptide Synthesis (LPPS) involves sequential amino acid coupling in a homogeneous solution, allowing precise control over reaction conditions and facilitating purification through liquid-liquid extraction or precipitation. LPPS eliminates the need for solid supports, enabling efficient monitoring of reaction progress via conventional analytical techniques like HPLC and NMR. This method is advantageous for synthesizing short to medium-length peptides with high purity and yield due to the ease of handling and scalability in solution-phase reactions.

Comparative Mechanisms: SPPS vs LPPS

Solid Phase Peptide Synthesis (SPPS) utilizes a solid resin support to anchor the growing peptide chain, allowing repetitive cycles of amino acid coupling and deprotection with simplified washing steps, which enhances automation and scalability. Liquid Phase Peptide Synthesis (LPPS) occurs entirely in solution, providing more homogeneous reaction conditions and better control over reaction kinetics, but requires tedious purification after each coupling. SPPS facilitates rapid assembly of complex peptides with efficient handling of reagents, whereas LPPS offers superior purity in intermediate products, making each suitable for distinct peptide synthesis applications based on length and complexity.

Efficiency and Yield Differences

Solid Phase Peptide Synthesis (SPPS) offers higher efficiency by enabling rapid chain assembly through automated cycles and simplified purification steps, leading to quicker peptide production. Liquid Phase Peptide Synthesis (LPPS) typically achieves higher overall yields due to better control over reaction conditions and fewer side reactions, especially for shorter peptides. The choice between SPPS and LPPS depends on the peptide length and complexity, with SPPS favored for automation and speed, while LPPS excels in maximizing yield for specific sequences.

Purification and Product Quality

Solid Phase Peptide Synthesis (SPPS) simplifies purification by anchoring the growing peptide chain to an insoluble resin, allowing excess reagents and by-products to be removed through simple washing steps. Liquid Phase Peptide Synthesis (LPPS) often requires complex chromatographic techniques for purification due to all reactants being in solution, leading to longer processing times and potential product loss. SPPS generally yields higher product quality with fewer side reactions and easier removal of impurities, while LPPS can provide better control over peptide length and sequence but demands meticulous purification to achieve comparable purity.

Cost Analysis: Economic Considerations

Solid Phase Peptide Synthesis (SPPS) reduces labor and purification costs through automation and resin reuse, making it cost-effective for complex, high-throughput peptide production. Liquid Phase Peptide Synthesis (LPPS) incurs higher expenses due to extensive solvent use, manual steps, and prolonged reaction times, impacting overall economic feasibility. Cost analysis favors SPPS in large-scale synthesis despite higher initial resin costs, while LPPS remains viable for small-scale, specialized peptide sequences.

Environmental Impact and Solvent Use

Solid Phase Peptide Synthesis (SPPS) significantly reduces solvent consumption and waste generation compared to Liquid Phase Peptide Synthesis (LPPS) due to its efficient resin-bound reaction cycles and simplified purification steps. LPPS typically requires large volumes of organic solvents for peptide isolation and purification, resulting in higher environmental impact and increased hazardous waste. SPPS offers enhanced sustainability by enabling solvent recycling and minimizing toxic solvent usage, aligning better with green chemistry principles.

Industrial and Research Applications

Solid Phase Peptide Synthesis (SPPS) offers higher efficiency and automation, making it the preferred method for large-scale industrial peptide production due to streamlined purification and scalability. Liquid Phase Peptide Synthesis (LPPS) provides better control over peptide sequences and yields, benefiting small-scale research applications where complex or longer peptides are synthesized with precise modification steps. Industry favors SPPS for mass production and cost-effectiveness, while LPPS remains valuable in academic and experimental contexts requiring detailed structural customization.

Future Trends in Peptide Synthesis Methods

Future trends in peptide synthesis emphasize automation and sustainability, with SPPS advancing through improved resin chemistries and greener solvents to enhance efficiency and reduce environmental impact. LPPS innovations focus on continuous flow techniques and scalable processes, enabling high-purity peptide production with reduced waste and cost. Integration of machine learning and real-time monitoring is driving precision and customization in both SPPS and LPPS, propelling the development of complex peptides for therapeutic applications.

Resin-bound peptides

Resin-bound peptides in Solid Phase Peptide Synthesis (SPPS) enable efficient, automated assembly with easy purification compared to Liquid Phase Peptide Synthesis (LPPS), which involves peptides free in solution but requires more complex separation methods.

Solution-phase condensation

Liquid Phase Peptide Synthesis (LPPS) via solution-phase condensation offers enhanced reaction monitoring and scalability compared to Solid Phase Peptide Synthesis (SPPS), facilitating higher purity peptides through improved control of reaction conditions and intermediate purification.

Boc/Fmoc strategies

Boc-based SPPS offers enhanced acid stability for peptide assembly compared to Fmoc-based LPPS, which provides milder base conditions facilitating longer peptide chains with fewer side reactions.

Peptide chain elongation

Solid Phase Peptide Synthesis (SPPS) enables rapid and efficient peptide chain elongation through sequential amino acid coupling on a solid resin, while Liquid Phase Peptide Synthesis (LPPS) involves peptide chain assembly in solution with more complex purification steps.

Cleavage protocols

SPPS utilizes selective resin-bound cleavage protocols with trifluoroacetic acid (TFA) for peptide release, while LPPS employs solution-phase cleavage often requiring harsher chemical reagents for peptide isolation.

Coupling efficiency

Solid Phase Peptide Synthesis (SPPS) typically achieves higher coupling efficiency than Liquid Phase Peptide Synthesis (LPPS) due to the simplified purification and driving excess reagents on the solid support.

Protecting group chemistry

Solid Phase Peptide Synthesis (SPPS) typically employs Fmoc or Boc protecting groups due to their stability and ease of removal on solid supports, whereas Liquid Phase Peptide Synthesis (LPPS) often uses more diverse protecting groups tailored for solubility and selective cleavage in solution-phase reactions.

Aggregation suppression

Solid Phase Peptide Synthesis (SPPS) effectively suppresses peptide aggregation through resin-bound intermediates, whereas Liquid Phase Peptide Synthesis (LPPS) requires careful solvent and additive selection to minimize aggregation during solution-phase reactions.

High-throughput synthesis

Solid Phase Peptide Synthesis (SPPS) enables high-throughput peptide production through automated, parallel synthesis and simplified purification compared to the labor-intensive, batch-wise Liquid Phase Peptide Synthesis (LPPS).

Crude peptide purification

Solid Phase Peptide Synthesis (SPPS) typically yields crude peptides requiring less purification due to resin-bound intermediates minimizing side reactions, whereas Liquid Phase Peptide Synthesis (LPPS) often produces complex mixtures demanding extensive purification steps to isolate target peptides.

SPPS vs LPPS (Solid Phase Peptide Synthesis vs Liquid Phase Peptide Synthesis) Infographic

njnir.com

njnir.com