Heat exchanger network (HEN) design optimizes thermal energy recovery by strategically arranging heat exchangers to minimize utility consumption. Pinch analysis identifies the minimum energy requirements and the pinch point, guiding the integration of heat exchangers to achieve maximum energy efficiency. Combining HEN design with pinch analysis results in a cost-effective, sustainable process with reduced operational expenses.

Table of Comparison

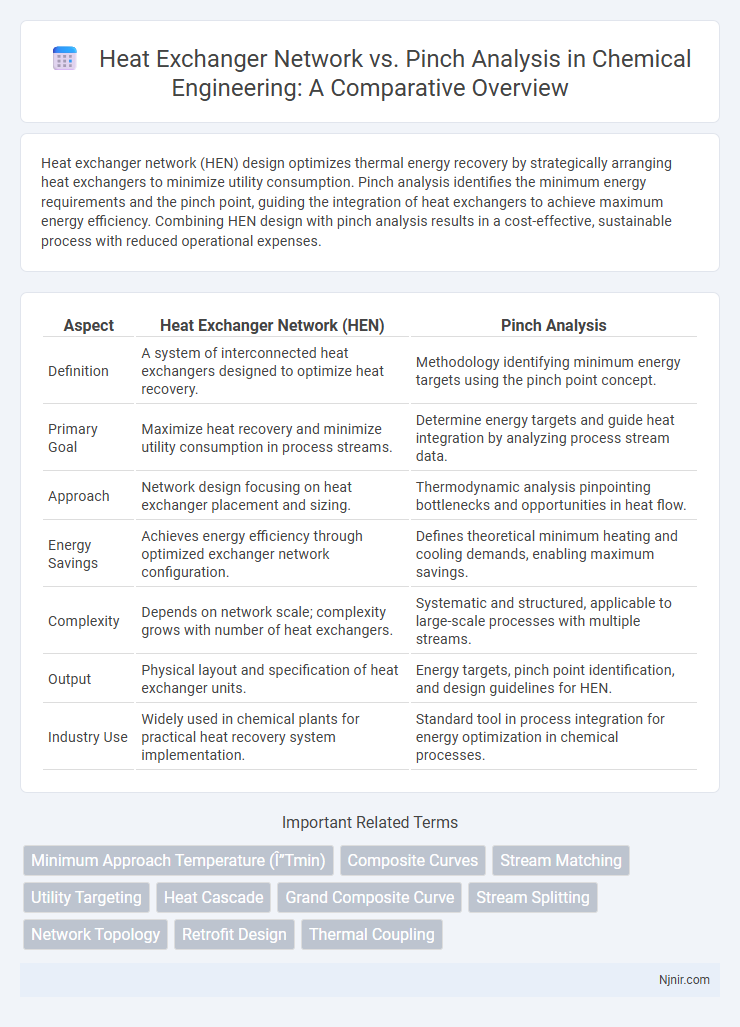

| Aspect | Heat Exchanger Network (HEN) | Pinch Analysis |

|---|---|---|

| Definition | A system of interconnected heat exchangers designed to optimize heat recovery. | Methodology identifying minimum energy targets using the pinch point concept. |

| Primary Goal | Maximize heat recovery and minimize utility consumption in process streams. | Determine energy targets and guide heat integration by analyzing process stream data. |

| Approach | Network design focusing on heat exchanger placement and sizing. | Thermodynamic analysis pinpointing bottlenecks and opportunities in heat flow. |

| Energy Savings | Achieves energy efficiency through optimized exchanger network configuration. | Defines theoretical minimum heating and cooling demands, enabling maximum savings. |

| Complexity | Depends on network scale; complexity grows with number of heat exchangers. | Systematic and structured, applicable to large-scale processes with multiple streams. |

| Output | Physical layout and specification of heat exchanger units. | Energy targets, pinch point identification, and design guidelines for HEN. |

| Industry Use | Widely used in chemical plants for practical heat recovery system implementation. | Standard tool in process integration for energy optimization in chemical processes. |

Introduction to Heat Exchanger Networks and Pinch Analysis

Heat exchanger networks (HENs) are systems designed to maximize heat recovery by integrating multiple heat exchangers, thereby reducing energy consumption in industrial processes. Pinch analysis is a methodology used to identify the minimum energy requirements and optimize heat recovery by analyzing temperature and heat flow data to locate the "pinch point," where heat transfer constraints are most critical. Combining HEN design with pinch analysis enables the creation of energy-efficient systems by strategically placing heat exchangers to achieve optimal thermal integration.

Fundamental Principles of Heat Exchanger Network Design

Heat exchanger network design is grounded in maximizing energy recovery by strategically matching hot and cold process streams to minimize external utility consumption. Pinch analysis identifies the thermodynamically most constrained point (pinch point) in the process, providing a systematic framework to determine minimum hot and cold utility requirements and guiding the optimal placement of heat exchangers. While heat exchanger network design focuses on practical arrangement and integration of exchangers, pinch analysis underpins the fundamental thermodynamic principles essential for achieving energy-efficient network optimization.

Core Concepts in Pinch Analysis

Pinch analysis centers on identifying the "pinch point," where the minimum temperature difference between hot and cold streams occurs, to optimize heat recovery and minimize external energy use. The method uses composite curves and grand composite curves to visually represent heat availability and requirements, enabling systematic targeting of energy savings. Heat exchanger network (HEN) design applies these principles to arrange exchangers efficiently, reducing capital and operating costs while ensuring thermal feasibility.

Comparative Overview: HENs vs. Pinch Analysis

Heat exchanger networks (HENs) optimize energy recovery by strategically integrating multiple heat exchangers to match hot and cold streams, focusing on practical equipment design and operational flexibility. Pinch analysis offers a theoretical framework that identifies the minimum energy targets and pinch point, enabling systematic energy saving by defining thermodynamic constraints. While HENs emphasize detailed heat exchanger configuration and real-world implementation, pinch analysis provides critical insights on optimal energy efficiency boundaries and guides network synthesis.

Process Integration Using Heat Exchanger Networks

Heat exchanger networks (HEN) optimize energy recovery by strategically connecting process streams for maximum heat exchange, reducing utility consumption and operational costs. Pinch analysis identifies the thermodynamically limiting point in the process, guiding the design and modification of HENs to achieve minimum energy targets and maximize efficiency. Combining pinch analysis with HEN design ensures systematic process integration, enhances heat recovery, and supports sustainable energy management in industrial processes.

Pinch Point Identification and Its Significance

Pinch analysis involves identifying the pinch point, the location where the minimum temperature difference between hot and cold streams occurs, which is critical for optimizing heat exchanger networks. Recognizing the pinch point allows engineers to maximize energy recovery by preventing heat transfer across this bottleneck, ensuring minimum utility consumption. This strategic identification directly influences the design and retrofit of heat exchanger networks, enhancing overall process efficiency and cost-effectiveness.

Energy Efficiency Optimization in Chemical Plants

Heat exchanger network (HEN) design maximizes energy recovery by strategically integrating process streams to reduce external heating and cooling demands, enhancing overall thermal efficiency in chemical plants. Pinch analysis identifies the minimum energy consumption targets by locating the pinch point, enabling optimal heat integration and effective allocation of utilities for energy efficiency optimization. Combining HEN design and pinch analysis leads to significant reductions in energy consumption, operational costs, and greenhouse gas emissions in industrial processes.

Key Advantages and Limitations of Each Method

Heat exchanger network (HEN) design optimizes energy recovery by integrating multiple heat exchangers, offering key advantages like reduced energy consumption and operational costs, but it can be complex and capital-intensive with limitations in handling large-scale system variations. Pinch analysis identifies the minimum energy requirements of a process by locating the pinch point, ensuring maximum energy recovery with straightforward implementation; however, it may oversimplify interactions and overlook detailed equipment design constraints. Both methods contribute to energy efficiency but differ in scope, with HEN offering detailed network optimization and Pinch analysis providing strategic guidance for process integration.

Case Studies: Practical Applications and Outcomes

Heat exchanger network (HEN) design often relies on case studies demonstrating improved energy efficiency through optimized heat recovery, with several industrial trials reporting energy savings of up to 30%. Pinch analysis cases illustrate systematic identification of thermodynamic limits, enabling minimum utility consumption and cost-effective retrofit opportunities, frequently achieving a 20-40% reduction in operating expenses. Comparative studies reveal pinch analysis is more effective in complex process integrations, while HEN design excels in straightforward heat recovery implementations, emphasizing the complementary roles in energy optimization strategies.

Future Trends in Process Heat Integration Techniques

Future trends in process heat integration techniques emphasize advanced Heat Exchanger Network (HEN) synthesis combined with Pinch Analysis to maximize energy efficiency and minimize carbon emissions. Integration of AI and machine learning enhances predictive modeling and optimization in complex industrial systems, while digital twins enable real-time monitoring and adaptive control of heat exchanger networks. The rise of renewable energy incorporation and waste heat recovery technologies drives innovation towards hybrid systems that leverage both HEN and Pinch methodologies for sustainable process intensification.

Minimum Approach Temperature (ΔTmin)

Minimum Approach Temperature (DTmin) in Pinch Analysis determines heat exchanger network design feasibility by setting the closest temperature difference for heat recovery, directly impacting energy savings and network complexity.

Composite Curves

Composite Curves in Pinch Analysis visually represent thermal energy availability and demand, enabling precise Heat Exchanger Network design to maximize energy recovery and minimize utility consumption.

Stream Matching

Heat exchanger network design optimizes energy recovery by stream matching hot and cold process streams, while pinch analysis identifies the minimum energy targets and pinch points to guide optimal stream integration.

Utility Targeting

Utility targeting in heat exchanger networks uses pinch analysis to identify minimum utility consumption by pinpointing temperature pinch points and guiding optimal heat recovery configurations.

Heat Cascade

Heat Cascade in Heat Exchanger Networks optimizes energy recovery by systematically analyzing temperature differences to minimize utility consumption, while Pinch Analysis identifies the pinch point to maximize heat recovery and guide network design.

Grand Composite Curve

The Grand Composite Curve in Pinch analysis visually represents the maximum heat recovery potential by highlighting heat surplus and deficit areas, enabling optimized Heat Exchanger Networks that minimize external utility consumption.

Stream Splitting

Heat exchanger network design using pinch analysis minimizes energy consumption by optimizing stream splitting at pinch points to enhance heat recovery efficiency.

Network Topology

Heat exchanger network topology optimizes energy integration by configuring heat exchanger placement and flow patterns, while pinch analysis identifies thermodynamic bottlenecks to guide network design for maximum energy recovery.

Retrofit Design

Pinch analysis optimizes retrofit design by identifying minimum energy targets and strategic heat exchanger placements, while heat exchanger network design focuses on configuring exchangers to maximize energy recovery within those targets.

Thermal Coupling

Thermal coupling in heat exchanger networks optimizes energy recovery by strategically matching hot and cold streams, while pinch analysis identifies the minimum utility requirements and critical temperature targets for maximizing heat integration efficiency.

Heat exchanger network vs Pinch analysis Infographic

njnir.com

njnir.com