Circular economy in chemical engineering emphasizes resource efficiency by recycling and reusing materials within closed-loop processes, minimizing waste and environmental impact. In contrast, the linear economy follows a 'take-make-dispose' model that depletes raw materials and generates significant waste. Transitioning to circular economy practices enhances sustainability by promoting innovation in chemical processes and materials management.

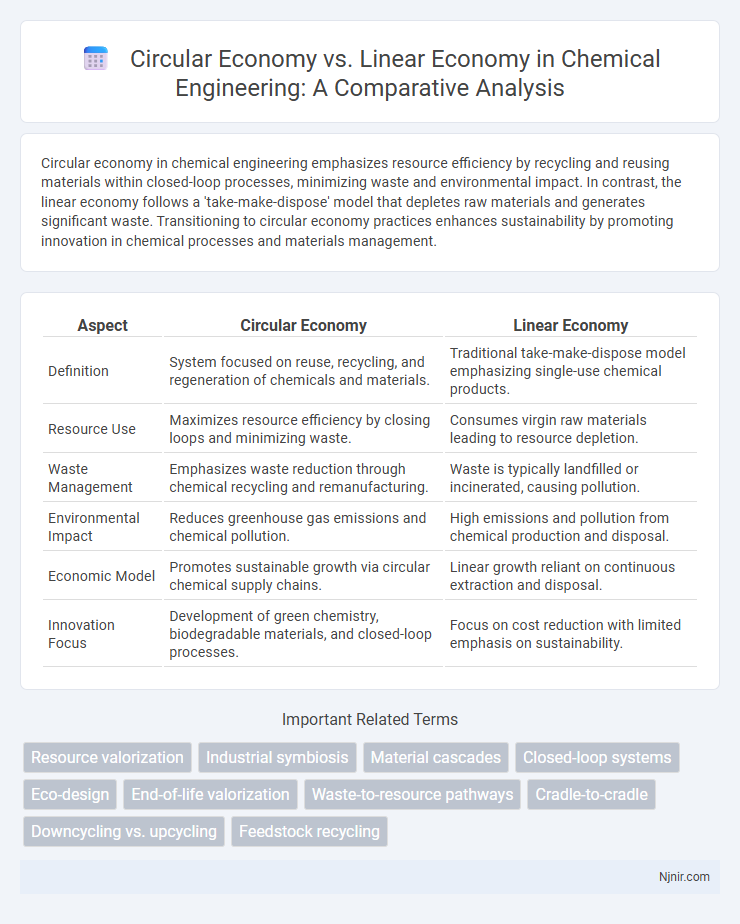

Table of Comparison

| Aspect | Circular Economy | Linear Economy |

|---|---|---|

| Definition | System focused on reuse, recycling, and regeneration of chemicals and materials. | Traditional take-make-dispose model emphasizing single-use chemical products. |

| Resource Use | Maximizes resource efficiency by closing loops and minimizing waste. | Consumes virgin raw materials leading to resource depletion. |

| Waste Management | Emphasizes waste reduction through chemical recycling and remanufacturing. | Waste is typically landfilled or incinerated, causing pollution. |

| Environmental Impact | Reduces greenhouse gas emissions and chemical pollution. | High emissions and pollution from chemical production and disposal. |

| Economic Model | Promotes sustainable growth via circular chemical supply chains. | Linear growth reliant on continuous extraction and disposal. |

| Innovation Focus | Development of green chemistry, biodegradable materials, and closed-loop processes. | Focus on cost reduction with limited emphasis on sustainability. |

Introduction to Circular and Linear Economies in Chemical Engineering

The circular economy in chemical engineering emphasizes resource efficiency by designing processes that minimize waste and enable material reuse, contrasting with the linear economy's traditional "take-make-dispose" model. Chemical engineers implement sustainable practices such as recycling solvents and catalysts to reduce environmental impact and enhance process sustainability. Transitioning to circular systems involves innovations in green chemistry and lifecycle analysis to optimize resource cycles and energy consumption.

Core Principles: Circular vs. Linear Economy

The core principle of a circular economy revolves around designing out waste and pollution, keeping products and materials in use through continuous cycles of reuse, repair, and recycling. Conversely, the linear economy follows a take-make-dispose model, where resources are extracted, transformed into products, and ultimately discarded as waste. Prioritizing resource efficiency and sustainability, circular systems aim to minimize environmental impact and foster long-term economic resilience.

Resource Utilization and Material Flows

The circular economy optimizes resource utilization by promoting closed-loop material flows, enabling reuse, recycling, and regeneration to minimize waste and reduce raw material extraction. In contrast, the linear economy follows a take-make-dispose model, leading to high resource depletion and significant waste generation as materials flow in a one-way trajectory from production to disposal. Emphasizing efficient material recovery and sustainable resource management, the circular economy aims to decouple economic growth from finite resource consumption.

Waste Generation and Management Approaches

Circular economy minimizes waste generation by prioritizing resource reuse, recycling, and regenerative design, significantly reducing landfill reliance and environmental impact. Linear economy follows a "take-make-dispose" model, leading to higher volumes of waste due to single-use products and limited recycling efforts. Effective waste management in a circular economy integrates closed-loop systems, promoting continuous material flow and reducing resource extraction.

Energy Efficiency in Production Processes

Circular economy enhances energy efficiency in production processes by prioritizing the reuse and recycling of materials, reducing the need for energy-intensive raw material extraction. In contrast, linear economy relies heavily on continuous resource consumption and disposal, leading to higher energy demand and waste generation. Implementing circular principles can reduce energy consumption in manufacturing by up to 50%, contributing to lower carbon emissions and sustainable industrial growth.

Lifecycle Assessment and Sustainability Metrics

Lifecycle Assessment (LCA) plays a crucial role in differentiating circular economy models from linear economy approaches by quantifying environmental impacts across the entire product lifecycle. Circular economy emphasizes minimizing resource extraction and waste generation, using sustainability metrics such as carbon footprint, water usage, and material circularity indicators to optimize product reuse, recycling, and remanufacturing. Linear economy models often lack comprehensive LCA integration, leading to higher environmental costs and inefficient resource utilization, whereas circular systems prioritize continuous resource loops to enhance overall sustainability performance.

Innovations Driving the Circular Economy in Chemistry

Innovations in chemistry are crucial for advancing the circular economy by developing sustainable materials and efficient recycling processes that minimize waste and resource depletion. Breakthroughs in bio-based polymers, catalytic depolymerization, and chemical recycling technologies enable the transformation of end-of-life plastics into high-quality raw materials. These chemical innovations support a regenerative system, reducing reliance on virgin resources and promoting closed-loop manufacturing across industries.

Economic and Environmental Impacts

The circular economy minimizes waste and resource extraction by promoting reuse, recycling, and sustainable design, leading to significant reductions in greenhouse gas emissions and resource depletion compared to the linear economy's take-make-dispose model. Economically, the circular economy fosters innovation, creates new job opportunities in recycling and remanufacturing sectors, and reduces costs associated with raw materials and waste management. In contrast, the linear economy often results in higher environmental degradation and long-term economic risks due to resource scarcity and increased pollution.

Challenges and Barriers to Implementation

Circular economy faces challenges such as high initial investment costs, complex supply chain reconfiguration, and lack of standardized metrics for measuring circularity. Linear economy benefits from established infrastructure and cost-efficiency but struggles with resource depletion and waste management issues. Barriers to implementing circular principles include regulatory gaps, limited consumer awareness, and resistance from industries accustomed to traditional production and disposal models.

Future Outlook for Circular Economy in Chemical Engineering

The future outlook for circular economy in chemical engineering highlights increased adoption of sustainable materials, waste valorization, and closed-loop processes that minimize resource depletion. Advanced catalytic technologies and bioprocess engineering are driving innovations enabling efficient recycling and upcycling of industrial by-products. Emphasis on life cycle assessment and regulatory frameworks accelerates integration of circular principles, aiming to transform chemical production into resilient, low-carbon systems.

Resource valorization

Circular economy maximizes resource valorization by continuously recycling and reusing materials, whereas linear economy often leads to resource depletion and waste through a one-way consumption model.

Industrial symbiosis

Industrial symbiosis in circular economy maximizes resource efficiency by enabling waste and by-products from one industry to serve as inputs for another, contrasting with the linear economy's extract-use-dispose model.

Material cascades

Circular economy maximizes resource efficiency by reusing and recycling materials through multiple cascades, while linear economy relies on a single-use, waste-generating extraction-to-disposal approach.

Closed-loop systems

Closed-loop systems in a circular economy minimize waste and resource use by continuously recycling materials, contrasting with the linear economy's single-use, disposal approach.

Eco-design

Eco-design in a circular economy prioritizes resource efficiency, product longevity, and recyclability to minimize waste, contrasting with the linear economy's focus on single-use and disposal.

End-of-life valorization

End-of-life valorization in a circular economy emphasizes resource recovery and recycling to minimize waste, whereas a linear economy typically leads to disposal and resource depletion.

Waste-to-resource pathways

Circular economy prioritizes waste-to-resource pathways by transforming waste into valuable materials through recycling, remanufacturing, and upcycling, whereas linear economy relies on a take-make-dispose model that generates more waste and depletes resources.

Cradle-to-cradle

Cradle-to-cradle design in circular economy eliminates waste by perpetually cycling materials, contrasting with the linear economy's take-make-dispose model that depletes resources and generates landfill.

Downcycling vs. upcycling

Circular economy prioritizes upcycling by transforming waste into higher-value products, whereas linear economy relies on downcycling, leading to lower-value material reuse and resource depletion.

Feedstock recycling

Feedstock recycling in a circular economy transforms waste into raw materials, reducing resource depletion compared to the linear economy's one-way consumption and disposal model.

Circular economy vs Linear economy Infographic

njnir.com

njnir.com