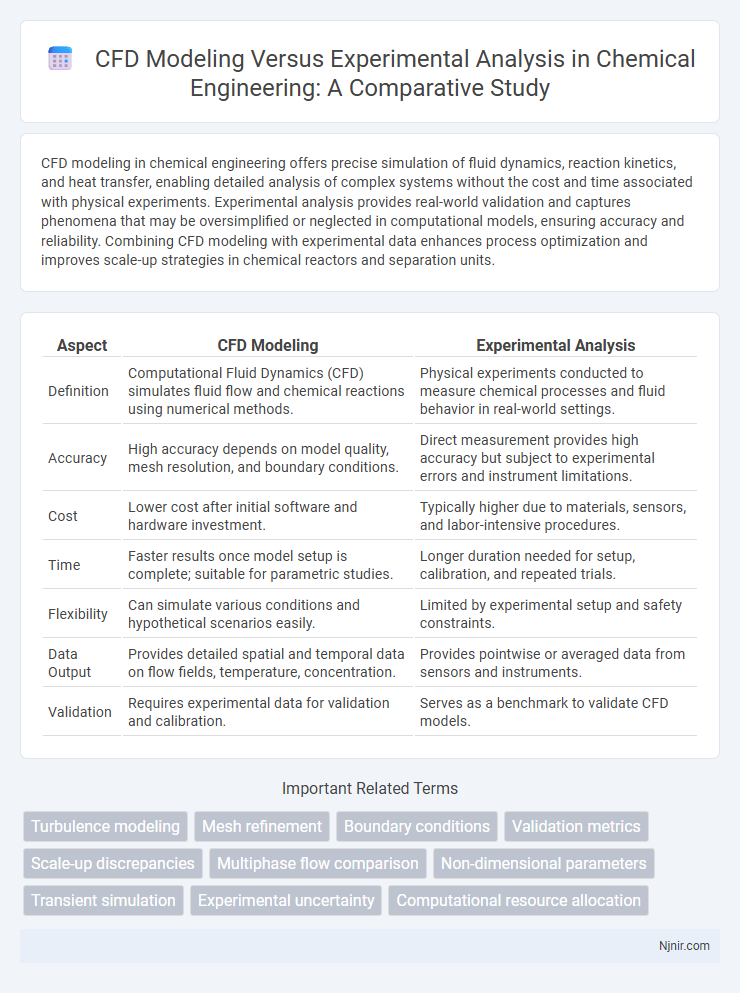

CFD modeling in chemical engineering offers precise simulation of fluid dynamics, reaction kinetics, and heat transfer, enabling detailed analysis of complex systems without the cost and time associated with physical experiments. Experimental analysis provides real-world validation and captures phenomena that may be oversimplified or neglected in computational models, ensuring accuracy and reliability. Combining CFD modeling with experimental data enhances process optimization and improves scale-up strategies in chemical reactors and separation units.

Table of Comparison

| Aspect | CFD Modeling | Experimental Analysis |

|---|---|---|

| Definition | Computational Fluid Dynamics (CFD) simulates fluid flow and chemical reactions using numerical methods. | Physical experiments conducted to measure chemical processes and fluid behavior in real-world settings. |

| Accuracy | High accuracy depends on model quality, mesh resolution, and boundary conditions. | Direct measurement provides high accuracy but subject to experimental errors and instrument limitations. |

| Cost | Lower cost after initial software and hardware investment. | Typically higher due to materials, sensors, and labor-intensive procedures. |

| Time | Faster results once model setup is complete; suitable for parametric studies. | Longer duration needed for setup, calibration, and repeated trials. |

| Flexibility | Can simulate various conditions and hypothetical scenarios easily. | Limited by experimental setup and safety constraints. |

| Data Output | Provides detailed spatial and temporal data on flow fields, temperature, concentration. | Provides pointwise or averaged data from sensors and instruments. |

| Validation | Requires experimental data for validation and calibration. | Serves as a benchmark to validate CFD models. |

Introduction to CFD Modeling and Experimental Analysis

Computational Fluid Dynamics (CFD) modeling uses numerical analysis and algorithms to simulate fluid flow, heat transfer, and related phenomena in complex systems, offering detailed insights into fluid behavior without physical prototypes. Experimental analysis involves direct measurement and observation of physical systems under controlled conditions to validate theoretical predictions and capture real-world behaviors. Both approaches are essential for fluid dynamics, with CFD providing flexible, cost-effective simulations and experiments delivering accurate empirical data for benchmarking and validation.

Fundamental Principles: CFD and Experimental Methods

CFD modeling relies on solving Navier-Stokes equations numerically to simulate fluid flow, heat transfer, and mass transport under various conditions, leveraging discretization methods such as Finite Volume or Finite Element to approximate solutions. Experimental analysis is based on physical measurements and observations using instruments like wind tunnels, PIV (Particle Image Velocimetry), or pressure sensors to obtain real-world data for validating theoretical models. Both methods emphasize principles of fluid dynamics and thermodynamics, but CFD utilizes computational algorithms for prediction while experimental methods provide empirical evidence and validation.

Advantages of CFD Modeling in Chemical Engineering

CFD modeling in chemical engineering offers precise simulation of fluid flow, heat transfer, and chemical reactions, enabling optimization of processes without costly physical prototypes. It provides detailed insights into complex systems, such as multiphase reactors and turbulent flows, which are difficult to capture experimentally. This approach significantly reduces development time and operational costs while enhancing scalability and safety assessments.

Experimental Analysis: Strengths and Limitations

Experimental analysis provides direct measurement of physical phenomena, offering high accuracy and validation for real-world conditions often unattainable by computational models. Its strength lies in the ability to capture complex fluid behavior, turbulence, and boundary interactions without assumptions inherent in CFD simulations. However, experimental methods can be costly, time-consuming, and limited by instrumentation resolution and scalability issues, making them less flexible for extensive parametric studies compared to CFD modeling.

Accuracy and Validation: CFD vs Experimental Data

Computational Fluid Dynamics (CFD) modeling offers detailed insights into complex fluid behaviors through numerical simulations, though its accuracy heavily depends on the chosen turbulence models, mesh quality, and boundary conditions. Experimental analysis provides empirical data that serve as a critical benchmark for validating CFD results, ensuring model reliability and identifying discrepancies in flow patterns or heat transfer predictions. Effective validation processes involve comparing velocity profiles, pressure distributions, and other key parameters between CFD simulations and experimental measurements to enhance predictive confidence.

Cost and Time Considerations in Process Optimization

Computational Fluid Dynamics (CFD) modeling significantly reduces cost and time compared to traditional experimental analysis by enabling virtual simulations that eliminate the need for physical prototypes. CFD accelerates process optimization through rapid iteration and detailed flow visualization, cutting development cycles from months to days. Experimental analysis, while providing empirical validation, generally incurs higher expenses and longer durations due to setup, material consumption, and labor-intensive testing.

Scalability: From Laboratory to Industrial Scale

CFD modeling provides scalable insights by simulating fluid dynamics across varying geometries and operating conditions, enabling predictions from laboratory setups to industrial-scale processes with reduced cost and time. Experimental analysis offers high accuracy and validation but faces challenges in replicating full-scale industrial environments due to equipment limitations and resource intensity. Combining CFD with targeted experimental data improves scalability and reliability in process design and optimization across scales.

Integration of CFD and Experimental Approaches

Integration of CFD modeling and experimental analysis enhances validation accuracy and design optimization in fluid dynamics studies. Combining high-fidelity computational simulations with empirical data enables the identification of model discrepancies and refinement of turbulence models, boundary conditions, and flow parameters. This hybrid approach improves predictive capabilities, reduces experimental costs, and accelerates the development of efficient aerodynamic and hydrodynamic systems.

Challenges and Uncertainties in CFD and Experiments

CFD modeling faces challenges such as mesh dependency, turbulence model selection, and numerical discretization errors, which introduce uncertainties in predicting complex fluid dynamics. Experimental analysis encounters uncertainties from measurement inaccuracies, sensor limitations, and environmental variations that can affect data reliability. Both approaches require careful validation and calibration to minimize errors and ensure accurate representation of physical phenomena.

Future Trends in Process Simulation and Validation

CFD modeling is rapidly evolving with advances in machine learning algorithms that enhance predictive accuracy and reduce computational time, enabling more complex process simulations. Experimental analysis continues to provide essential validation data, but future trends emphasize hybrid approaches integrating real-time sensor data with digital twins for dynamic process optimization. The convergence of AI-driven simulation and high-fidelity experiments will foster more robust, adaptive, and efficient process validation frameworks in industries such as chemical engineering and manufacturing.

Turbulence modeling

CFD turbulence modeling uses numerical simulations to predict complex fluid flow patterns with adjustable parameters, while experimental analysis provides empirical data through physical measurements, offering validation and insights into real-world turbulent behavior.

Mesh refinement

Mesh refinement in CFD modeling enhances simulation accuracy by increasing grid resolution, whereas experimental analysis relies on physical measurements unaffected by computational mesh quality.

Boundary conditions

Accurate boundary conditions in CFD modeling are crucial for replicating real-world experimental analysis results and ensuring reliable simulations of fluid dynamics.

Validation metrics

Validation metrics such as Root Mean Square Error (RMSE), Mean Absolute Percentage Error (MAPE), and R-squared (R2) are critical for comparing the accuracy of CFD modeling against experimental analysis results in fluid dynamics studies.

Scale-up discrepancies

CFD modeling often reveals scale-up discrepancies by accurately predicting fluid dynamics and heat transfer phenomena that experimental analysis may overlook due to practical limitations in replicating large-scale industrial conditions.

Multiphase flow comparison

CFD modeling offers detailed visualization and parametric control for multiphase flow analysis, while experimental analysis provides real-world validation and captures complex physical phenomena often challenging for simulations.

Non-dimensional parameters

Non-dimensional parameters such as Reynolds, Nusselt, and Prandtl numbers critically enhance the accuracy and scalability of CFD modeling compared to experimental analysis by enabling generalized fluid flow and heat transfer predictions across varying physical conditions.

Transient simulation

CFD modeling enables detailed transient simulation of fluid dynamics with precise temporal resolution, providing insights into time-dependent behaviors that experimental analysis may struggle to capture due to limitations in measurement speed and spatial accessibility.

Experimental uncertainty

Experimental analysis in fluid dynamics exhibits higher uncertainty due to measurement errors and environmental variability, whereas CFD modeling offers controlled simulations with quantifiable numerical uncertainties.

Computational resource allocation

CFD modeling requires significant computational resource allocation compared to experimental analysis, enabling detailed flow simulations but demanding high-performance hardware and longer processing times.

CFD modeling vs Experimental analysis Infographic

njnir.com

njnir.com