Membrane filtration offers superior separation efficiency by selectively allowing specific molecules to pass through semi-permeable membranes, unlike conventional filtration methods that rely on particle size exclusion. This advanced technology reduces energy consumption and enhances product purity, making it ideal for applications requiring precise contaminant removal. Membrane systems provide scalability and flexibility, improving operational control compared to traditional filtration techniques.

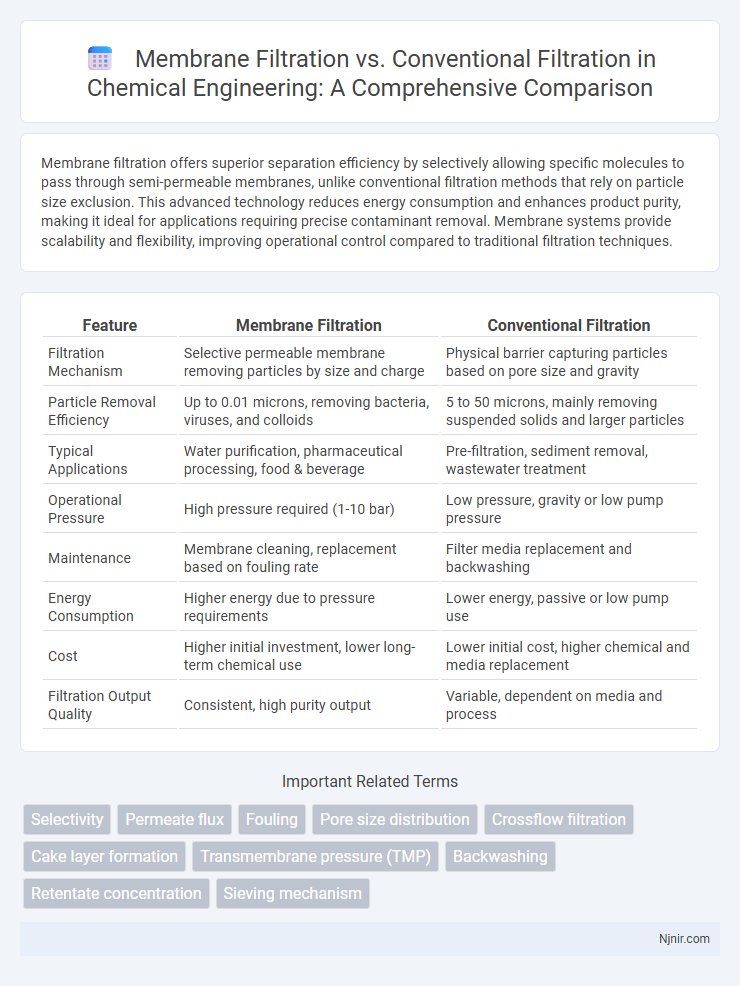

Table of Comparison

| Feature | Membrane Filtration | Conventional Filtration |

|---|---|---|

| Filtration Mechanism | Selective permeable membrane removing particles by size and charge | Physical barrier capturing particles based on pore size and gravity |

| Particle Removal Efficiency | Up to 0.01 microns, removing bacteria, viruses, and colloids | 5 to 50 microns, mainly removing suspended solids and larger particles |

| Typical Applications | Water purification, pharmaceutical processing, food & beverage | Pre-filtration, sediment removal, wastewater treatment |

| Operational Pressure | High pressure required (1-10 bar) | Low pressure, gravity or low pump pressure |

| Maintenance | Membrane cleaning, replacement based on fouling rate | Filter media replacement and backwashing |

| Energy Consumption | Higher energy due to pressure requirements | Lower energy, passive or low pump use |

| Cost | Higher initial investment, lower long-term chemical use | Lower initial cost, higher chemical and media replacement |

| Filtration Output Quality | Consistent, high purity output | Variable, dependent on media and process |

Overview of Filtration Techniques in Chemical Engineering

Membrane filtration employs semi-permeable membranes to selectively separate particles based on size and molecular weight, offering high precision in chemical engineering processes such as wastewater treatment and product purification. Conventional filtration relies on physical barriers like sand, cloth, or cartridge filters, efficiently removing suspended solids but often lacking the fine separation capabilities of membrane systems. Membrane filtration typically achieves higher removal efficiency for micro and nanoparticles, making it suitable for applications demanding stringent purity and contaminant control.

Principles of Membrane Filtration

Membrane filtration operates on the principle of selective permeability, using semi-permeable membranes to separate particles based on size, shape, and molecular weight, allowing only specific molecules or ions to pass through. Unlike conventional filtration, which relies on mechanical sieving or gravity to remove larger particles, membrane filtration can achieve finer separation at the microfiltration, ultrafiltration, nanofiltration, or reverse osmosis levels. This process is highly effective in water purification, wastewater treatment, and chemical processing, offering enhanced contaminant removal and improved product purity.

Fundamentals of Conventional Filtration Methods

Conventional filtration methods rely on gravity, pressure, or vacuum to separate particles based on size or sedimentation rate using materials such as sand, cloth, or paper. These systems typically operate with coarse or deep bed filters designed to remove suspended solids but may struggle with fine particulates and microbial contaminants. Efficiency in conventional filtration depends heavily on factors like filter media type, flow rate, and particle characteristics, which limits its effectiveness for applications requiring ultra-pure or sterile filtrates.

Key Differences: Membrane vs. Conventional Filtration

Membrane filtration uses semi-permeable membranes to selectively separate particles based on size and molecular characteristics, offering higher precision and the ability to remove viruses, bacteria, and colloids that conventional filtration might miss. Conventional filtration relies on porous media like sand or gravel to physically trap larger particles, making it less effective against micron and submicron contaminants. Membrane filtration systems typically provide higher water quality and require less chemical treatment, whereas conventional filtration is generally simpler and more cost-effective for large-scale, lower-purity applications.

Efficiency and Performance Comparison

Membrane filtration offers superior efficiency in removing contaminants such as bacteria, viruses, and suspended solids compared to conventional filtration methods, which primarily rely on gravity or mechanical sieving. Performance metrics indicate membrane systems achieve higher rejection rates and consistent water quality with lower chemical usage and smaller footprint requirements. Conventional filtration typically exhibits lower capital costs but struggles with variable flow rates and reduced contaminant removal efficiency, making membrane filtration the preferred choice for advanced water purification.

Applications in Chemical Processing

Membrane filtration in chemical processing offers precise separation of molecules, enabling selective removal of contaminants, recovery of valuable products, and efficient solvent recycling with minimal chemical additives. Conventional filtration is primarily applied for bulk solid-liquid separation, handling coarse particulates and precipitates, often requiring chemical coagulation or flocculation for improved efficacy. Membrane technologies such as ultrafiltration and nanofiltration are preferred in applications demanding high purity, like catalyst recovery and wastewater treatment, due to their fine molecular cutoff and operational scalability.

Energy Consumption and Operational Costs

Membrane filtration systems typically consume less energy due to lower pressure requirements compared to conventional filtration methods such as sand or cartridge filters, which operate at higher pressures and flow rates. Operational costs for membrane filtration can be higher initially due to membrane replacement and fouling management, but long-term expenses are often offset by reduced chemical usage and lower maintenance demands. Energy efficiency combined with optimized operational protocols makes membrane filtration a cost-effective choice for modern water treatment applications.

Maintenance and Lifespan Considerations

Membrane filtration systems typically require more specialized maintenance due to the susceptibility of membranes to fouling, scaling, and biological growth, necessitating regular chemical cleaning to sustain performance. Conventional filtration, such as sand or cartridge filters, generally involves simpler maintenance involving backwashing and media replacement, resulting in lower operational complexity. Membrane lifespan ranges from 3 to 7 years depending on feed water quality and maintenance rigor, whereas conventional filter media may require more frequent replacement but usually has a lower upfront cost and simpler maintenance routines.

Environmental Impact and Sustainability

Membrane filtration significantly reduces chemical usage and waste compared to conventional filtration, lowering environmental pollution and energy consumption. It offers higher water recovery rates and produces less sludge, contributing to sustainable water management practices. These advantages make membrane filtration a more eco-friendly and efficient choice in water treatment systems.

Future Trends in Filtration Technologies

Future trends in filtration technologies emphasize membrane filtration due to its enhanced selectivity, higher flux rates, and lower chemical usage compared to conventional filtration methods like sand or gravity filters. Innovations in nanofiltration and ultrafiltration membranes are driving advancements in water treatment, wastewater recovery, and industrial process optimization by enabling the removal of smaller contaminants with greater energy efficiency. Integration of membrane filters with smart monitoring systems and renewable energy sources is poised to revolutionize filtration performance and sustainability in diverse applications.

Selectivity

Membrane filtration offers higher selectivity by precisely separating particles based on size and molecular properties, whereas conventional filtration relies primarily on mechanical sieving with lower specificity.

Permeate flux

Membrane filtration offers a consistently higher permeate flux compared to conventional filtration due to its selective barrier and enhanced fouling resistance.

Fouling

Membrane filtration experiences higher fouling rates due to smaller pore sizes compared to conventional filtration, necessitating more frequent cleaning and maintenance for optimal performance.

Pore size distribution

Membrane filtration offers a narrower and more uniform pore size distribution, typically ranging from nanometers to micrometers, enabling higher selectivity compared to the broader and less consistent pore size distribution found in conventional filtration methods such as sand or cartridge filters.

Crossflow filtration

Crossflow filtration, a type of membrane filtration, offers higher efficiency and better prevention of membrane fouling compared to conventional dead-end filtration by continuously sweeping the membrane surface to reduce cake layer buildup.

Cake layer formation

Membrane filtration minimizes cake layer formation by using selective barriers that retain particles on the membrane surface, whereas conventional filtration relies on porous media where particle accumulation forms a thicker cake layer, reducing filtration efficiency.

Transmembrane pressure (TMP)

Membrane filtration operates at a higher transmembrane pressure (TMP) ranging from 0.1 to 1.0 bar compared to conventional filtration's TMP of approximately 0.02 to 0.05 bar, enabling more efficient separation and filtration performance.

Backwashing

Membrane filtration requires less frequent and more efficient backwashing compared to conventional filtration, resulting in improved system longevity and lower operational costs.

Retentate concentration

Membrane filtration achieves higher retentate concentration by selectively retaining particles and solutes with precision, whereas conventional filtration typically results in lower retentate concentration due to less selective separation mechanisms.

Sieving mechanism

Membrane filtration relies on a precise sieving mechanism using semipermeable membranes to separate particles based on size, whereas conventional filtration depends on porous media that trap particles through depth filtration and surface straining.

Membrane filtration vs Conventional filtration Infographic

njnir.com

njnir.com