Digital twin technology enables real-time simulation and optimization of chemical processes, significantly reducing the reliance on costly and time-consuming physical prototyping. By creating a virtual replica of chemical systems, engineers can predict performance, identify potential issues, and experiment with process modifications without interrupting actual production. This approach enhances process efficiency, accelerates development cycles, and improves overall safety compared to traditional physical prototype testing.

Table of Comparison

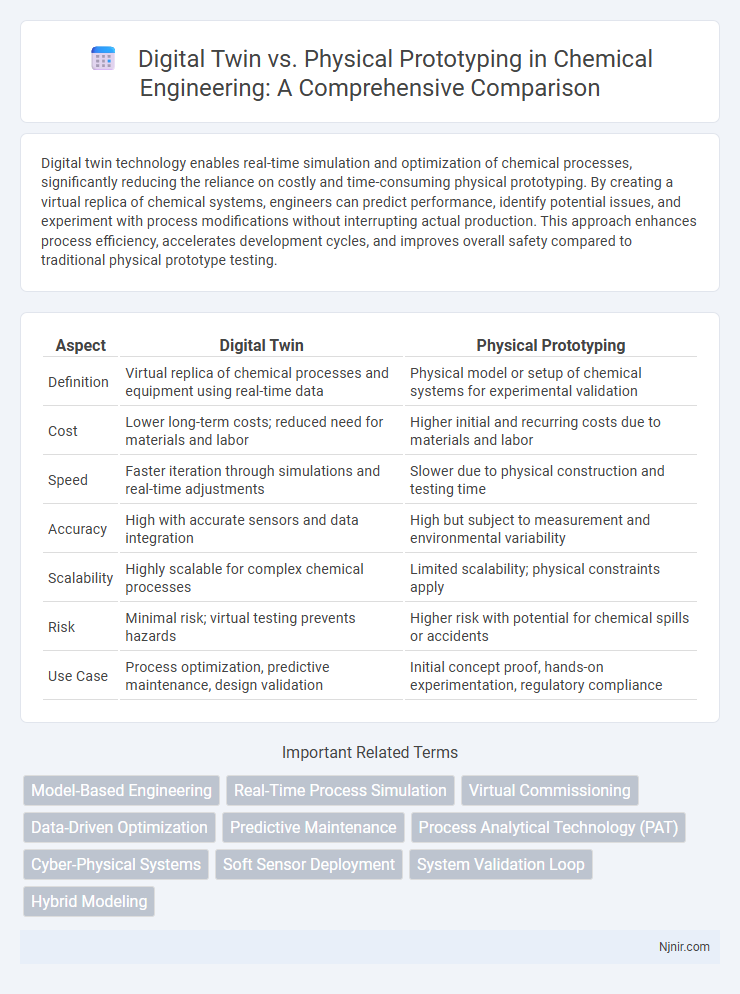

| Aspect | Digital Twin | Physical Prototyping |

|---|---|---|

| Definition | Virtual replica of chemical processes and equipment using real-time data | Physical model or setup of chemical systems for experimental validation |

| Cost | Lower long-term costs; reduced need for materials and labor | Higher initial and recurring costs due to materials and labor |

| Speed | Faster iteration through simulations and real-time adjustments | Slower due to physical construction and testing time |

| Accuracy | High with accurate sensors and data integration | High but subject to measurement and environmental variability |

| Scalability | Highly scalable for complex chemical processes | Limited scalability; physical constraints apply |

| Risk | Minimal risk; virtual testing prevents hazards | Higher risk with potential for chemical spills or accidents |

| Use Case | Process optimization, predictive maintenance, design validation | Initial concept proof, hands-on experimentation, regulatory compliance |

Introduction to Digital Twins and Physical Prototyping

Digital twins are virtual replicas of physical assets, systems, or processes that enable real-time data simulation and analysis to optimize performance and predict failures. Physical prototyping involves creating tangible models or functional versions of a product to test design concepts, materials, and user interactions in actual environments. Digital twins reduce time and cost by enabling virtual testing and iterative improvements without the need for multiple physical prototypes.

Key Differences Between Digital Twins and Physical Prototypes

Digital twins provide real-time simulation and data integration, enabling continuous monitoring and predictive analytics, whereas physical prototypes offer tangible, hands-on testing and direct interaction. Digital twins can be rapidly updated and scaled across various scenarios, while physical prototypes often require significant time and cost for modifications. The digital twin excels in virtual validation and remote troubleshooting, whereas physical prototypes are essential for physical stress testing and user experience evaluation.

Advantages of Digital Twin Technology in Chemical Engineering

Digital Twin technology in chemical engineering enables real-time monitoring and predictive maintenance, significantly reducing downtime and operational risks compared to physical prototyping. It allows for precise simulation of complex chemical processes under varying conditions, facilitating optimization and innovation without the high costs associated with traditional lab experiments. Enhanced data integration and analytics support improved decision-making and accelerated development cycles, driving efficiency and sustainability in chemical plant operations.

Limitations and Challenges of Digital Twins

Digital twins face limitations such as high initial implementation costs, complex data integration from diverse sources, and the need for continuous updates to maintain accuracy. Challenges include ensuring real-time data synchronization, managing cybersecurity risks, and addressing the potential gaps between virtual models and physical system behaviors. These constraints can hinder the full replacement of traditional physical prototyping in certain industries.

Benefits of Physical Prototyping in Process Design

Physical prototyping in process design offers tangible validation of product functionality, allowing engineers to detect unforeseen issues that digital twins might overlook. It provides real-world feedback on ergonomics, material behavior, and manufacturability, ensuring better alignment with production constraints. Hands-on testing accelerates iterative improvements, reducing downstream costs associated with design errors.

Drawbacks of Physical Prototyping Methods

Physical prototyping methods often incur high costs due to material usage and manufacturing time, limiting iterative testing and rapid innovation. These traditional approaches can be inflexible, making it challenging to modify designs quickly or explore multiple variations efficiently. Moreover, physical prototypes may not accurately replicate real-world conditions, leading to less precise performance evaluations compared to digital twin simulations.

Cost and Time Comparison: Digital Twin vs Physical Prototype

Digital twins significantly reduce cost and development time compared to physical prototyping by enabling virtual simulations and real-time data analysis without the need for expensive materials or manufacturing processes. Physical prototypes require substantial investment in resources and labor, often extending project timelines due to iterative testing and modifications. Leveraging digital twin technology accelerates product validation and optimizes design decisions, leading to faster market entry and lower overall expenses.

Case Studies: Digital Twin Implementation in Chemical Processes

Case studies in chemical processes reveal significant efficiency improvements through Digital Twin implementation, enabling real-time monitoring and predictive maintenance. Digital Twins provide detailed simulation data that surpasses traditional physical prototyping by reducing costs and accelerating design iteration cycles. Companies like BASF and Dow leverage Digital Twins to optimize reactor performance, minimizing downtime and enhancing product quality in complex chemical production environments.

Integration of Digital Twins with Industry 4.0 and IoT

Digital Twin technology integrates seamlessly with Industry 4.0 and IoT by providing real-time data synchronization between physical assets and their virtual counterparts, enabling predictive maintenance and enhanced operational efficiency. Unlike traditional physical prototyping, Digital Twins facilitate continuous monitoring and data-driven decision-making through IoT sensor networks and cloud computing platforms. This integration accelerates product development cycles, reduces costs, and supports advanced analytics for smart manufacturing environments.

Future Trends in Chemical Engineering Prototyping

Digital twin technology in chemical engineering prototyping enables real-time simulation and optimization of complex processes, significantly reducing the need for costly physical prototypes. Future trends highlight enhanced integration of AI-driven predictive analytics and IoT sensors to create more accurate and adaptive digital twins, accelerating development cycles. This shift promises to improve scalability, sustainability, and safety in chemical plant design and operation.

Model-Based Engineering

Model-Based Engineering leverages Digital Twin technology to enhance accuracy and reduce costs compared to traditional Physical Prototyping by enabling real-time simulation and data integration throughout the product lifecycle.

Real-Time Process Simulation

Digital twin technology enables real-time process simulation to optimize design and performance, surpassing the static analysis limitations of traditional physical prototyping.

Virtual Commissioning

Virtual commissioning leverages digital twin technology to simulate and validate physical prototypes, significantly reducing time and costs associated with traditional physical prototyping processes.

Data-Driven Optimization

Digital Twin enables real-time, data-driven optimization by simulating physical prototypes, reducing development time and costs while enhancing performance accuracy.

Predictive Maintenance

Digital Twin technology enables real-time data analysis and predictive maintenance by simulating physical prototypes, reducing downtime and maintenance costs through accurate failure forecasting.

Process Analytical Technology (PAT)

Digital Twin technology enhances Process Analytical Technology (PAT) by providing real-time simulation and predictive analytics, significantly reducing the need for costly physical prototyping in manufacturing processes.

Cyber-Physical Systems

Cyber-physical systems leverage digital twin technology to create dynamic virtual models that enhance design accuracy and reduce costs compared to traditional physical prototyping.

Soft Sensor Deployment

Digital Twin technology enhances Soft Sensor deployment by enabling real-time simulation and predictive analytics, outperforming traditional Physical Prototyping in efficiency and accuracy.

System Validation Loop

Digital Twin enhances the System Validation Loop by enabling real-time simulation and iterative testing of virtual models, reducing reliance on costly and time-consuming physical prototyping.

Hybrid Modeling

Hybrid modeling in digital twins integrates physical prototyping data with virtual simulations to enhance accuracy, reduce development costs, and accelerate product innovation.

Digital Twin vs Physical Prototyping Infographic

njnir.com

njnir.com