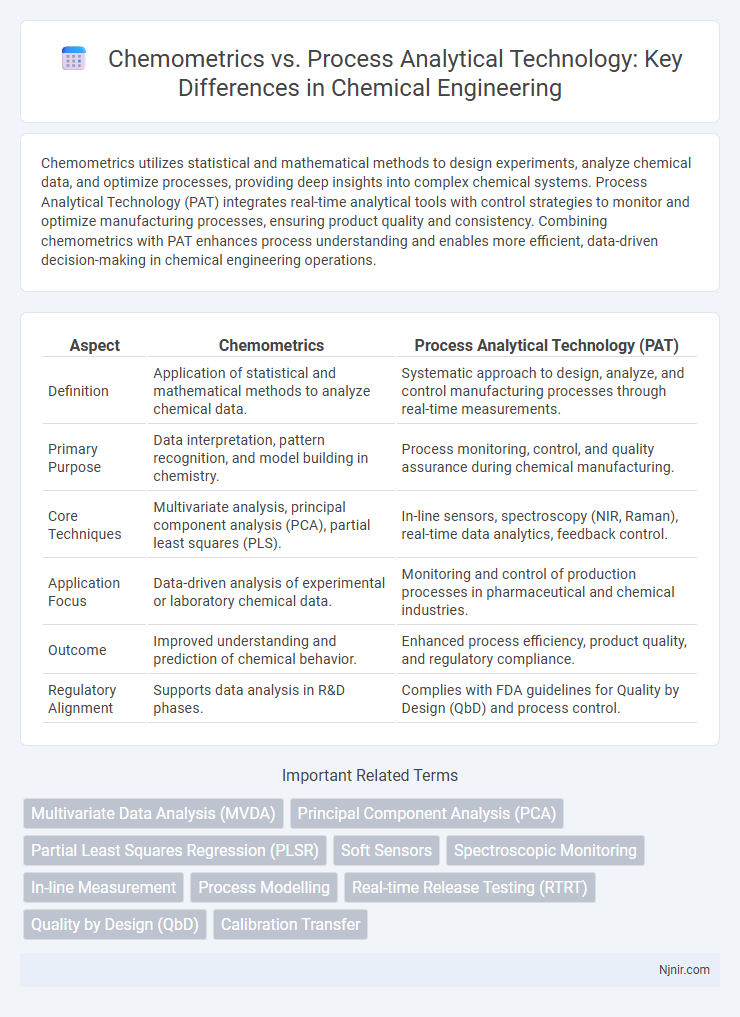

Chemometrics utilizes statistical and mathematical methods to design experiments, analyze chemical data, and optimize processes, providing deep insights into complex chemical systems. Process Analytical Technology (PAT) integrates real-time analytical tools with control strategies to monitor and optimize manufacturing processes, ensuring product quality and consistency. Combining chemometrics with PAT enhances process understanding and enables more efficient, data-driven decision-making in chemical engineering operations.

Table of Comparison

| Aspect | Chemometrics | Process Analytical Technology (PAT) |

|---|---|---|

| Definition | Application of statistical and mathematical methods to analyze chemical data. | Systematic approach to design, analyze, and control manufacturing processes through real-time measurements. |

| Primary Purpose | Data interpretation, pattern recognition, and model building in chemistry. | Process monitoring, control, and quality assurance during chemical manufacturing. |

| Core Techniques | Multivariate analysis, principal component analysis (PCA), partial least squares (PLS). | In-line sensors, spectroscopy (NIR, Raman), real-time data analytics, feedback control. |

| Application Focus | Data-driven analysis of experimental or laboratory chemical data. | Monitoring and control of production processes in pharmaceutical and chemical industries. |

| Outcome | Improved understanding and prediction of chemical behavior. | Enhanced process efficiency, product quality, and regulatory compliance. |

| Regulatory Alignment | Supports data analysis in R&D phases. | Complies with FDA guidelines for Quality by Design (QbD) and process control. |

Introduction to Chemometrics and Process Analytical Technology

Chemometrics involves the application of mathematical and statistical methods to design experiments and analyze chemical data, optimizing data interpretation in complex chemical processes. Process Analytical Technology (PAT) integrates real-time analytical measurements to monitor and control manufacturing processes, improving product quality and efficiency. Both chemometrics and PAT play critical roles in advancing process understanding, with chemometrics providing data analysis tools and PAT offering in-line process monitoring capabilities.

Defining Chemometrics in Chemical Engineering

Chemometrics in chemical engineering involves the application of mathematical, statistical, and computational techniques to extract relevant information from complex chemical data sets. It enables the optimization of processes, quality control, and decision-making by modeling chemical systems and interpreting process analytical technology (PAT) data. Chemometrics serves as a critical tool within PAT frameworks for real-time monitoring and controlling chemical manufacturing processes.

Overview of Process Analytical Technology (PAT)

Process Analytical Technology (PAT) is a system for designing, analyzing, and controlling manufacturing through timely measurements of critical quality and performance attributes of raw and in-process materials. It integrates various analytical tools, including chemometrics, to monitor and optimize processes in real-time, ensuring consistent product quality. PAT enhances process understanding and reduces variability by enabling rapid data acquisition and process adjustments.

Core Principles: Chemometrics vs Process Analytical Technology

Chemometrics applies mathematical and statistical techniques to extract relevant information from complex chemical data, emphasizing data-driven model development and multivariate analysis. Process Analytical Technology (PAT) integrates real-time monitoring and control strategies within manufacturing, focusing on understanding and controlling processes to ensure product quality. Core principles of chemometrics involve data interpretation and pattern recognition, while PAT centers on process understanding and optimization through inline or online measurement systems.

Applications of Chemometrics in Process Monitoring

Chemometrics plays a crucial role in process monitoring by transforming complex data from analytical instruments into actionable insights, enabling real-time quality control and optimization in manufacturing. Techniques such as multivariate data analysis, pattern recognition, and calibration models enhance the detection of process deviations, ensuring product consistency and reducing waste. These applications complement process analytical technology (PAT) frameworks by providing robust statistical tools that improve process understanding and decision-making.

PAT Tools and Techniques in Chemical Manufacturing

Chemometrics and process analytical technology (PAT) are integral to enhancing chemical manufacturing through data-driven process optimization. PAT tools such as spectroscopy (NIR, Raman), chromatography, and multivariate data analysis leverage chemometric techniques for real-time monitoring and control of critical process parameters. The combination of chemometrics with PAT enables robust process understanding, reduced variability, and improved product quality in continuous and batch chemical production.

Integration of Chemometrics with PAT Systems

Integration of chemometrics with process analytical technology (PAT) systems enhances real-time data analysis by applying multivariate statistical techniques to process measurements, enabling precise monitoring and control of manufacturing processes. This synergy improves process understanding, quality assurance, and efficiency by transforming complex sensor data into actionable insights. Advanced chemometric models within PAT frameworks facilitate robust prediction, fault detection, and continuous process optimization in pharmaceutical and chemical industries.

Benefits and Limitations of Each Approach

Chemometrics enhances data interpretation and predictive modeling in process analytical technology (PAT), enabling real-time quality control and process optimization with improved accuracy and efficiency. PAT offers direct monitoring and control of manufacturing processes, reducing variability and ensuring consistent product quality, but it may require significant initial investment and complex integration. Chemometrics relies heavily on statistical methods and large datasets, which can limit its effectiveness if data quality is poor or if models are not properly validated.

Case Studies: Real-world Implementations

Chemometrics enhances process analytical technology (PAT) by enabling precise data analysis and model development in pharmaceutical manufacturing, as demonstrated in case studies involving real-time quality control and process optimization. Implementation examples include real-time NIR spectroscopy for blending uniformity and multivariate statistical process control (MSPC) for identifying deviations in continuous manufacturing lines. These successes highlight improved product consistency and reduced waste through integrating chemometric algorithms with PAT tools in industrial settings.

Future Trends in Chemometrics and PAT for Chemical Engineering

Future trends in chemometrics and process analytical technology (PAT) highlight the integration of advanced machine learning algorithms with real-time data analytics to optimize chemical engineering processes. The evolving use of multivariate statistical methods and sensor fusion techniques enhances process monitoring, control, and quality assurance in pharmaceutical and chemical manufacturing. Emerging developments emphasize the automation of PAT systems, enabling predictive maintenance and adaptive process optimization for sustainable and efficient production.

Multivariate Data Analysis (MVDA)

Multivariate Data Analysis (MVDA) in chemometrics enables comprehensive interpretation of complex datasets, while process analytical technology (PAT) applies MVDA techniques for real-time monitoring and control of manufacturing processes.

Principal Component Analysis (PCA)

Principal Component Analysis (PCA) in Chemometrics enhances data interpretation by reducing dimensionality and identifying patterns, while in Process Analytical Technology (PAT), PCA optimizes real-time process monitoring and control for improved manufacturing efficiency.

Partial Least Squares Regression (PLSR)

Partial Least Squares Regression (PLSR) serves as a crucial chemometric tool in process analytical technology (PAT) for modeling complex multivariate data to enhance real-time process monitoring and control.

Soft Sensors

Soft sensors in chemometrics leverage multivariate data analysis to provide real-time process monitoring and control, while process analytical technology (PAT) integrates these soft sensors with advanced instrumentation to enhance manufacturing efficiency and product quality.

Spectroscopic Monitoring

Chemometrics enhances Process Analytical Technology by applying advanced statistical algorithms to spectroscopic monitoring data for real-time process optimization and quality control.

In-line Measurement

In-line measurement in Chemometrics uses statistical models for real-time data analysis of chemical processes, while Process Analytical Technology integrates sensor-based in-line measurements for continuous monitoring and control in manufacturing.

Process Modelling

Process Modelling in chemometrics involves developing statistical models to interpret chemical data for quality control, whereas Process Analytical Technology (PAT) integrates real-time process data and predictive models to optimize manufacturing processes.

Real-time Release Testing (RTRT)

Chemometrics enhances Process Analytical Technology (PAT) by enabling real-time data analysis and modeling to facilitate accurate Real-time Release Testing (RTRT) in pharmaceutical manufacturing.

Quality by Design (QbD)

Chemometrics enhances Quality by Design (QbD) in Process Analytical Technology (PAT) by providing advanced multivariate data analysis for real-time process monitoring and control.

Calibration Transfer

Calibration transfer in chemometrics enables seamless adaptation of predictive models across different instruments, enhancing the effectiveness of process analytical technology in real-time quality monitoring.

Chemometrics vs process analytical technology Infographic

njnir.com

njnir.com