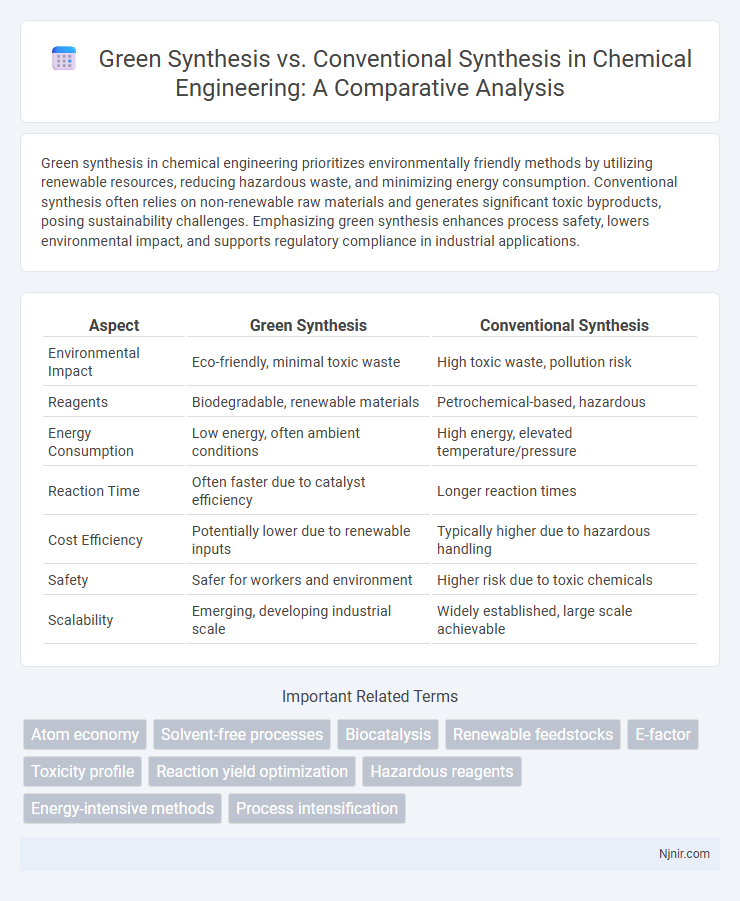

Green synthesis in chemical engineering prioritizes environmentally friendly methods by utilizing renewable resources, reducing hazardous waste, and minimizing energy consumption. Conventional synthesis often relies on non-renewable raw materials and generates significant toxic byproducts, posing sustainability challenges. Emphasizing green synthesis enhances process safety, lowers environmental impact, and supports regulatory compliance in industrial applications.

Table of Comparison

| Aspect | Green Synthesis | Conventional Synthesis |

|---|---|---|

| Environmental Impact | Eco-friendly, minimal toxic waste | High toxic waste, pollution risk |

| Reagents | Biodegradable, renewable materials | Petrochemical-based, hazardous |

| Energy Consumption | Low energy, often ambient conditions | High energy, elevated temperature/pressure |

| Reaction Time | Often faster due to catalyst efficiency | Longer reaction times |

| Cost Efficiency | Potentially lower due to renewable inputs | Typically higher due to hazardous handling |

| Safety | Safer for workers and environment | Higher risk due to toxic chemicals |

| Scalability | Emerging, developing industrial scale | Widely established, large scale achievable |

Introduction to Chemical Synthesis Methods

Green synthesis utilizes environmentally benign reagents and sustainable processes to minimize hazardous byproducts and reduce energy consumption, contrasting sharply with conventional synthesis, which often involves toxic chemicals and generates significant waste. This eco-friendly approach emphasizes renewable resources and safer reaction conditions, aligning with principles of green chemistry to promote sustainability in chemical manufacturing. Conventional synthesis remains widely used due to established protocols and scalability but faces increasing scrutiny for environmental and health impacts driving the adoption of greener alternatives.

Defining Green Synthesis in Chemical Engineering

Green synthesis in chemical engineering refers to the design and development of chemical processes that reduce or eliminate the use and generation of hazardous substances, emphasizing sustainability and eco-friendliness. It utilizes renewable feedstocks, energy-efficient methods, and environmentally benign solvents to minimize waste and toxicity during chemical production. This approach contrasts with conventional synthesis, which often relies on petroleum-based reagents, high energy consumption, and produces significant hazardous waste.

Conventional Synthesis: Overview and Principles

Conventional synthesis involves traditional chemical processes that often rely on hazardous reagents, high energy consumption, and generate significant waste, impacting environmental sustainability. It prioritizes reaction yield, purity, and reproducibility using established catalysts, solvents, and temperature controls to achieve desired chemical transformations. Despite its efficiency in industrial-scale production, conventional synthesis poses challenges related to toxicity, cost, and ecological footprint compared to emerging green synthesis methodologies.

Environmental Impact: Green vs Conventional Methods

Green synthesis minimizes environmental impact by using eco-friendly solvents, renewable materials, and energy-efficient processes, significantly reducing hazardous waste and toxic emissions compared to conventional synthesis. Conventional methods often rely on toxic chemicals, heavy metals, and non-renewable resources, leading to higher pollution levels and increased ecological risks. The adoption of green synthesis supports sustainable development by lowering carbon footprints and promoting biodegradability in chemical production.

Energy Efficiency in Synthesis Processes

Green synthesis techniques significantly enhance energy efficiency by utilizing ambient temperatures and pressures, reducing the overall energy consumption compared to conventional synthesis methods that often require high temperatures and prolonged reaction times. Renewable catalysts and solvents in green synthesis further minimize energy-intensive purification steps, promoting sustainable chemical production. This eco-friendly approach not only lowers carbon footprints but also aligns with industry goals for cost-effective and energy-efficient synthesis processes.

Use of Solvents and Reagents: Sustainability Comparison

Green synthesis prioritizes the use of eco-friendly solvents such as water or ethanol, reducing toxic waste generation and minimizing environmental impact compared to conventional synthesis, which often relies on hazardous organic solvents like benzene or dichloromethane. Reagents in green synthesis are typically biodegradable, non-toxic, and derived from renewable resources, enhancing sustainability by lowering chemical hazards and energy consumption. Conventional methods commonly use non-renewable, toxic reagents that contribute to higher environmental footprint and pose health risks during synthesis and disposal processes.

Cost Analysis: Green vs Conventional Approaches

Green synthesis methods reduce costs by minimizing the use of expensive and hazardous chemicals, lowering waste disposal expenses, and often utilizing renewable raw materials. Conventional synthesis typically incurs higher operational costs due to extensive energy consumption, toxic reagents, and stringent environmental compliance requirements. Economic evaluations reveal that green synthesis approaches can enhance cost efficiency while promoting sustainability and reducing environmental impact.

Safety and Health Considerations in Synthesis

Green synthesis prioritizes the use of non-toxic, biodegradable reagents and solvents, significantly reducing exposure to hazardous chemicals and minimizing health risks for researchers and the environment. Conventional synthesis often involves toxic reagents, volatile solvents, and high-energy input, which increase potential chemical hazards, waste generation, and occupational health concerns. Emphasizing sustainable practices, green synthesis enhances laboratory safety by lowering toxicity and exposure while promoting eco-friendly reaction conditions.

Advances and Innovations in Green Synthesis

Green synthesis leverages environmentally friendly reagents, solvents, and energy-efficient methods, significantly reducing hazardous waste compared to conventional synthesis, which often relies on toxic chemicals and high energy consumption. Innovations in green synthesis include the use of biocatalysts, microwave-assisted reactions, and renewable feedstocks, enhancing reaction efficiency and selectivity while minimizing environmental impact. Recent advances such as nanoparticle-mediated synthesis and solvent-free processes demonstrate a scalable approach aligned with sustainable chemistry principles, offering promising alternatives to traditional synthetic routes.

Future Prospects and Industrial Adoption

Green synthesis offers significant future prospects through eco-friendly processes that reduce hazardous waste and lower energy consumption, aligning with stricter environmental regulations. Industrial adoption is accelerating as companies seek sustainable alternatives, driven by cost efficiency, renewable feedstocks, and consumer demand for greener products. Conventional synthesis methods face increasing challenges due to their environmental impact and regulatory pressure, prompting a strategic shift toward green chemistry solutions in pharmaceutical, chemical, and materials industries.

Atom economy

Green synthesis achieves higher atom economy by minimizing waste and maximizing the incorporation of all reactants into the final product compared to conventional synthesis methods.

Solvent-free processes

Solvent-free green synthesis methods reduce environmental impact and enhance reaction efficiency compared to conventional synthesis relying on toxic solvents.

Biocatalysis

Biocatalysis in green synthesis uses natural enzymes to achieve eco-friendly, cost-effective, and highly selective chemical transformations, contrasting with conventional synthesis that relies on harsh chemicals and energy-intensive processes.

Renewable feedstocks

Green synthesis utilizes renewable feedstocks to reduce environmental impact, whereas conventional synthesis relies primarily on non-renewable, fossil-based feedstocks.

E-factor

Green synthesis drastically reduces the E-factor by minimizing waste and using safer, renewable materials compared to conventional synthesis methods that generate higher environmental impact through toxic byproducts.

Toxicity profile

Green synthesis methods significantly reduce toxicity by utilizing non-toxic, renewable materials and environmentally benign processes, unlike conventional synthesis which often involves hazardous chemicals and generates toxic byproducts.

Reaction yield optimization

Green synthesis enhances reaction yield optimization by using eco-friendly catalysts and milder conditions that minimize by-products compared to conventional synthesis methods.

Hazardous reagents

Green synthesis minimizes the use of hazardous reagents by employing environmentally friendly solvents and catalysts, whereas conventional synthesis often relies on toxic chemicals and generates harmful byproducts.

Energy-intensive methods

Green synthesis reduces energy consumption by using eco-friendly catalysts and milder reaction conditions compared to conventional synthesis, which relies heavily on energy-intensive methods like high temperatures and pressures.

Process intensification

Green synthesis enhances process intensification by using eco-friendly catalysts and solvents that reduce energy consumption and waste generation compared to conventional synthesis methods.

Green synthesis vs Conventional synthesis Infographic

njnir.com

njnir.com