Fuzzy logic control offers enhanced adaptability and robustness in managing nonlinear and complex chemical processes compared to traditional PID control, which relies on precise mathematical models and tuning. By mimicking human reasoning, fuzzy logic controllers can handle uncertainties and variable conditions without requiring exact system parameters, improving stability and performance. Although PID control remains effective for linear and well-defined systems, fuzzy logic provides superior flexibility in dynamic and uncertain chemical engineering environments.

Table of Comparison

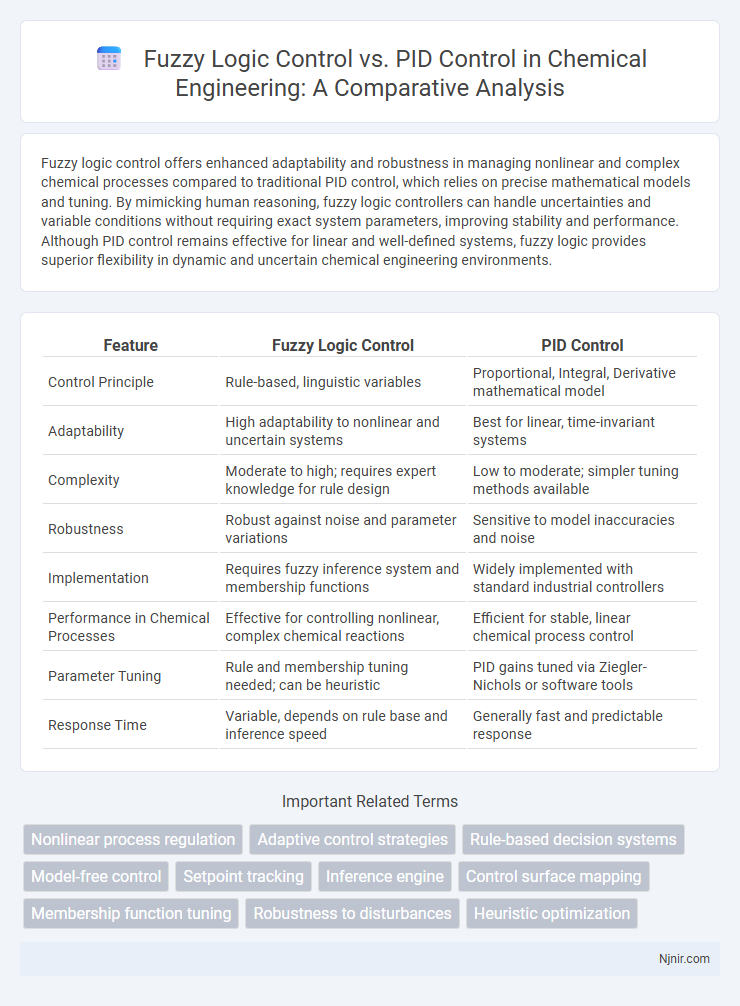

| Feature | Fuzzy Logic Control | PID Control |

|---|---|---|

| Control Principle | Rule-based, linguistic variables | Proportional, Integral, Derivative mathematical model |

| Adaptability | High adaptability to nonlinear and uncertain systems | Best for linear, time-invariant systems |

| Complexity | Moderate to high; requires expert knowledge for rule design | Low to moderate; simpler tuning methods available |

| Robustness | Robust against noise and parameter variations | Sensitive to model inaccuracies and noise |

| Implementation | Requires fuzzy inference system and membership functions | Widely implemented with standard industrial controllers |

| Performance in Chemical Processes | Effective for controlling nonlinear, complex chemical reactions | Efficient for stable, linear chemical process control |

| Parameter Tuning | Rule and membership tuning needed; can be heuristic | PID gains tuned via Ziegler-Nichols or software tools |

| Response Time | Variable, depends on rule base and inference speed | Generally fast and predictable response |

Introduction to Process Control in Chemical Engineering

Fuzzy logic control offers a heuristic approach to process control by handling uncertainties and nonlinearities in chemical engineering systems, unlike traditional PID control, which relies on precise mathematical models. PID controllers maintain process variables through proportional, integral, and derivative actions but may struggle with complex, dynamic chemical processes. Fuzzy logic systems interpret expert knowledge and linguistic variables, enhancing adaptability and robustness in controlling chemical reactors, distillation columns, or heat exchangers.

Fundamentals of PID Control in Chemical Processes

PID control in chemical processes relies on proportional, integral, and derivative terms to continuously adjust process variables, ensuring stability and minimizing error from setpoints. The proportional component responds to current error, the integral addresses accumulated past errors, and the derivative predicts future errors based on rate of change, making PID effective for linear and time-invariant systems. Fuzzy logic control differs by handling uncertainties and nonlinearities through rule-based reasoning, whereas PID control excels in well-modeled environments with predictable system dynamics.

Principles of Fuzzy Logic Control Systems

Fuzzy logic control systems operate based on approximate reasoning and linguistic variables, enabling them to handle uncertainty and nonlinearity by mimicking human decision-making processes. Unlike PID controllers that rely on precise mathematical models and error correction, fuzzy controllers use a rule-based system with fuzzy sets and membership functions to infer control actions. This approach allows fuzzy logic controllers to adapt dynamically to varying system behaviors without requiring an exact model, enhancing robustness in complex or nonlinear control environments.

Comparison of Control Strategies: Fuzzy Logic vs PID

Fuzzy logic control and PID control differ fundamentally in handling system dynamics, with fuzzy logic offering adaptive rule-based decision-making that manages nonlinearities and uncertainties effectively, while PID control relies on fixed gain parameters reacting to error signals for linear systems. Fuzzy logic controllers excel in systems where precise mathematical models are unavailable, providing robustness against model inaccuracies, whereas PID controllers are preferred for their simplicity, ease of implementation, and efficiency in well-defined, stable processes. Performance comparison reveals fuzzy logic maintains better stability and performance in complex, nonlinear environments, while PID control provides faster response and minimal steady-state error in linear or mildly nonlinear systems.

Response to Nonlinear and Complex Chemical Processes

Fuzzy logic control excels in managing nonlinear and complex chemical processes by mimicking human reasoning to handle uncertainties and system nonlinearities without requiring an accurate mathematical model. PID control, while effective for linear and time-invariant systems, often struggles with nonlinearities and parameter variations, leading to suboptimal performance or instability. Integrating fuzzy logic with PID controllers enhances adaptability and robustness, improving response time and control accuracy in dynamic chemical process environments.

Robustness and Adaptability in Control Approaches

Fuzzy logic control offers superior robustness and adaptability compared to PID control by effectively handling nonlinearities and uncertainties without requiring precise mathematical models. PID control, while simple and widely used, often struggles with parameter tuning and deteriorates in performance when system dynamics change or disturbances occur. The fuzzy approach dynamically adjusts control actions based on linguistic rules, enhancing resilience in complex and varying environments.

Implementation Challenges in Industrial Settings

Fuzzy logic control faces implementation challenges in industrial settings due to its reliance on expert knowledge for rule base development and the complexity of tuning membership functions. PID control, while widely used and easier to implement, struggles with nonlinear systems and time-varying parameters, requiring frequent retuning to maintain performance. Industrial applications demand robust controllers, and integrating fuzzy logic often involves higher computational resources and difficulties in formal validation compared to the straightforward mathematical foundation of PID controllers.

Performance Evaluation: Case Studies and Applications

Fuzzy logic control demonstrates superior performance in handling nonlinear systems and uncertainties, outperforming traditional PID control in adaptive and complex environments, as evidenced by case studies in robotics and automotive systems. Applications in temperature regulation and process control reveal that fuzzy controllers achieve faster response times and reduced overshoot compared to PID controllers, particularly under variable operating conditions. Performance evaluation metrics emphasize fuzzy logic's robustness and flexibility, making it suitable for real-time control applications where precise tuning of PID parameters is challenging.

Future Trends in Chemical Process Automation

Fuzzy logic control offers adaptive decision-making advantages over traditional PID control by handling nonlinearities and uncertainties inherent in chemical processes, enabling more robust automation solutions. Emerging trends emphasize integrating machine learning with fuzzy logic controllers to enhance predictive capabilities and real-time optimization in complex chemical production systems. Advances in sensor technology and computational power further support the shift towards hybrid control frameworks that combine fuzzy logic adaptability with PID precision, driving future innovation in chemical process automation.

Conclusion: Choosing the Optimal Control Method

Fuzzy logic control offers adaptability and robustness in complex, nonlinear systems where precise mathematical models are difficult to obtain, making it suitable for dynamic and uncertain environments. PID control excels in systems with well-defined linear characteristics, providing simplicity, ease of implementation, and fine-tuned stability for steady-state performance. Selecting the optimal control method depends on system complexity, required precision, and environmental variability, with fuzzy logic favored for uncertainty management and PID preferred for straightforward, predictable processes.

Nonlinear process regulation

Fuzzy logic control outperforms PID control in nonlinear process regulation by handling uncertainties and dynamic changes without requiring precise mathematical models.

Adaptive control strategies

Fuzzy logic control adapts to nonlinear system dynamics by interpreting imprecise inputs through rule-based reasoning, whereas PID control relies on fixed parameters that require manual tuning or adaptive algorithms to handle system variations effectively.

Rule-based decision systems

Fuzzy logic control utilizes rule-based decision systems to handle uncertainty and nonlinearities in processes more effectively than traditional PID control, which relies on fixed mathematical models and precise error correction.

Model-free control

Fuzzy logic control offers robust model-free control by handling system uncertainties and nonlinearities without precise mathematical models, unlike PID control which relies on accurate system modeling for optimal performance.

Setpoint tracking

Fuzzy logic control offers superior setpoint tracking in nonlinear and uncertain systems by adapting control rules dynamically, whereas PID control provides precise setpoint tracking primarily in linear, well-modeled environments.

Inference engine

Fuzzy logic control uses a rule-based inference engine to handle imprecise inputs and nonlinear systems, whereas PID control relies on a mathematical model without an inference engine.

Control surface mapping

Fuzzy logic control provides a more flexible and adaptive control surface mapping than PID control by handling nonlinearities and uncertainties through rule-based inference rather than fixed proportional-integral-derivative parameters.

Membership function tuning

Fuzzy logic control outperforms PID control in complex systems by optimizing membership function tuning to enhance adaptability and precision in nonlinear process regulation.

Robustness to disturbances

Fuzzy logic control demonstrates superior robustness to disturbances compared to PID control by effectively handling nonlinearities and uncertainties in dynamic systems without requiring precise mathematical models.

Heuristic optimization

Fuzzy logic control utilizes heuristic optimization to handle nonlinear systems with uncertainty more effectively than traditional PID control by adapting rules based on expert knowledge.

Fuzzy logic control vs PID control Infographic

njnir.com

njnir.com