Fluidized bed reactors offer superior mixing and heat transfer compared to packed bed reactors, reducing channeling and hot spots during chemical reactions. Packed bed reactors provide higher catalyst surface area per unit volume, beneficial for processes requiring high conversion efficiency under steady flow conditions. Choice between these reactors depends on reaction kinetics, catalyst type, and process scalability requirements.

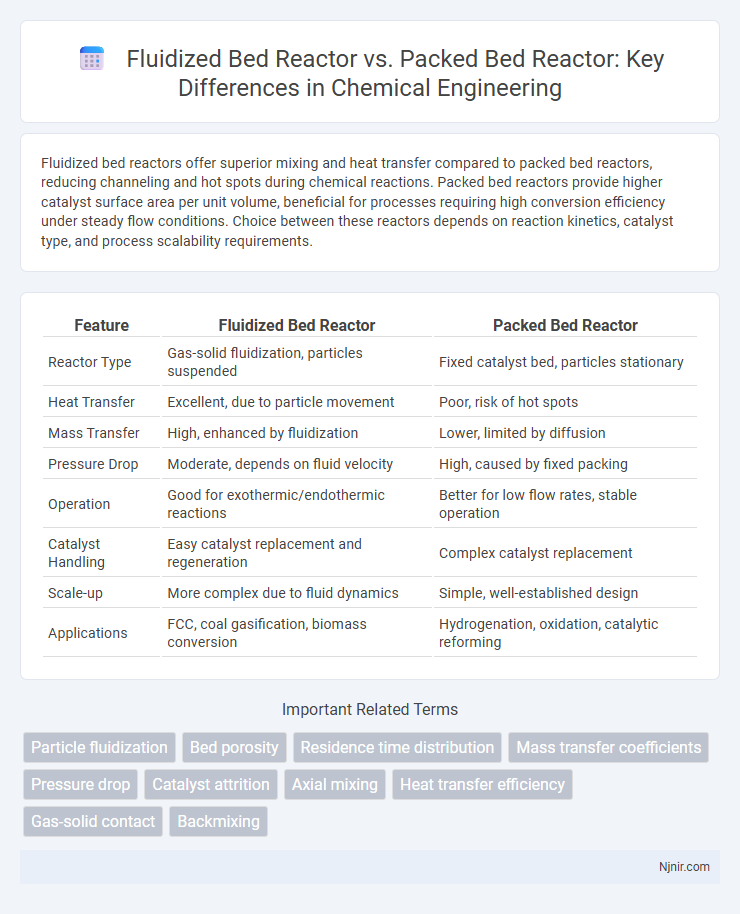

Table of Comparison

| Feature | Fluidized Bed Reactor | Packed Bed Reactor |

|---|---|---|

| Reactor Type | Gas-solid fluidization, particles suspended | Fixed catalyst bed, particles stationary |

| Heat Transfer | Excellent, due to particle movement | Poor, risk of hot spots |

| Mass Transfer | High, enhanced by fluidization | Lower, limited by diffusion |

| Pressure Drop | Moderate, depends on fluid velocity | High, caused by fixed packing |

| Operation | Good for exothermic/endothermic reactions | Better for low flow rates, stable operation |

| Catalyst Handling | Easy catalyst replacement and regeneration | Complex catalyst replacement |

| Scale-up | More complex due to fluid dynamics | Simple, well-established design |

| Applications | FCC, coal gasification, biomass conversion | Hydrogenation, oxidation, catalytic reforming |

Introduction to Fluidized Bed and Packed Bed Reactors

Fluidized bed reactors use a fluid to suspend solid catalyst particles, enhancing heat and mass transfer due to increased mixing and uniform temperature distribution. Packed bed reactors consist of a fixed bed of catalyst particles through which reactants flow, offering high surface area but limited mixing and potential channeling. Fluidized beds are preferred for processes requiring efficient heat removal and handling of solids, whereas packed beds suit reactions with steady-state, plug-flow conditions.

Fundamental Operating Principles

Fluidized bed reactors operate by suspending solid catalyst particles in an upward flow of gas or liquid, creating a dynamic mixing environment that enhances heat and mass transfer. Packed bed reactors contain a fixed arrangement of catalyst particles through which the reactant fluid flows, relying on convection and diffusion for reaction progression. The fluidized bed's turbulent motion reduces channeling and hotspots, whereas the packed bed offers a simpler design with lower pressure drop but limited mixing efficiency.

Reactor Design and Construction Differences

Fluidized bed reactors feature a bed of solid catalyst particles suspended by an upward flow of fluid, allowing for enhanced heat and mass transfer through improved mixing and uniform temperature distribution. Packed bed reactors consist of fixed catalyst particles tightly packed into the reactor vessel, leading to potential channeling and limited heat transfer compared to fluidized beds. The construction of fluidized bed reactors demands stronger vessel materials to withstand particle abrasion and dynamic fluidization, while packed bed reactors require precise packing to minimize pressure drop and ensure catalyst stability.

Hydrodynamics and Flow Characteristics

Fluidized bed reactors exhibit excellent gas-solid contact due to suspended particles creating a turbulent flow, enhancing mass and heat transfer rates, while packed bed reactors maintain a fixed particle arrangement leading to laminar or transitional flow with limited mixing. The fluidized bed's dynamic particle movement results in uniform temperature distribution and reduced channeling, contrasting with packed beds where channeling and pressure drop issues are more prevalent. Hydrodynamic behavior in fluidized beds enables higher throughput and flexible operation, whereas packed beds offer simpler design but suffer from lower flow uniformity and potential clogging risks.

Heat and Mass Transfer Efficiency

Fluidized bed reactors exhibit superior heat and mass transfer efficiency due to vigorous particle movement and intense mixing, enhancing uniform temperature distribution and reactant accessibility. Packed bed reactors often suffer from channeling and hot spots, leading to uneven heat transfer and limited mass transfer rates within the fixed catalyst bed. The high surface area contact and dynamic nature of fluidized beds significantly improve reaction kinetics compared to the relatively stagnant environment of packed beds.

Catalyst Utilization and Regeneration

Fluidized bed reactors offer superior catalyst utilization by ensuring uniform particle suspension and enhanced mass transfer, leading to better contact between reactants and catalyst surfaces. Catalyst regeneration is more efficient in fluidized bed systems due to continuous circulation and effective heat management, minimizing coke deposition and allowing in-situ regeneration. Packed bed reactors typically face challenges with catalyst deactivation and hot spots, making catalyst regeneration less uniform and often requiring shutdowns for replacement or external regeneration.

Scale-Up and Industrial Applications

Fluidized bed reactors offer superior scale-up potential due to enhanced heat and mass transfer rates, enabling uniform temperature distribution ideal for large-scale catalytic reactions and combustion processes. Packed bed reactors face challenges in scale-up because of pressure drop increase and channeling effects, limiting uniform flow and temperature control, often confining use to smaller or modular industrial applications such as adsorption and fixed-bed catalysis. Industrial operations favor fluidized bed reactors in processes like fluid catalytic cracking (FCC) and biomass gasification, while packed bed reactors are prominent in chemical synthesis and gas purification where precise residence time is critical.

Advantages and Limitations of Fluidized Bed Reactors

Fluidized bed reactors offer superior heat and mass transfer rates compared to packed bed reactors, enabling uniform temperature distribution and enhanced catalyst efficiency in processes like catalytic cracking and combustion. Their advantages include excellent mixing, reduced channeling, and scalability for handling large solid volumes; however, limitations encompass higher operational complexity, potential particle attrition, and challenges in maintaining stable fluidization at varying flow rates. These reactors are ideal for reactions requiring precise temperature control and continuous solid handling but may incur higher capital and maintenance costs relative to packed bed designs.

Benefits and Challenges of Packed Bed Reactors

Packed bed reactors offer high catalytic surface area and efficient heat transfer, making them ideal for processes involving gas-solid reactions. Their main benefits include simplicity, low operational cost, and the ability to achieve high conversion rates with minimal catalyst attrition. Challenges include pressure drop issues, potential channeling effects, and difficulty in temperature control during highly exothermic reactions.

Selection Criteria for Industrial Processes

Fluidized bed reactors offer superior heat and mass transfer, making them ideal for processes involving catalytic cracking, combustion, or polymerization where temperature control is critical. Packed bed reactors provide higher catalyst loading and simpler design, suitable for reactions with lower heat generation or when operating under high pressure and low flow rates. Selection criteria depend on factors such as reaction kinetics, thermal management needs, catalyst sensitivity, and operational scalability in industrial applications.

Particle fluidization

Fluidized bed reactors achieve enhanced particle fluidization by suspending solid particles in an upward-flowing fluid, improving mass and heat transfer compared to the fixed particle arrangement in packed bed reactors.

Bed porosity

Fluidized bed reactors exhibit higher bed porosity due to particle suspension, enhancing mass transfer compared to the lower porosity and limited flow channels in packed bed reactors.

Residence time distribution

Fluidized bed reactors exhibit narrower and more uniform residence time distribution compared to packed bed reactors, enhancing mixing efficiency and reaction consistency.

Mass transfer coefficients

Fluidized bed reactors exhibit higher mass transfer coefficients than packed bed reactors due to enhanced particle mixing and improved gas-solid contact efficiency.

Pressure drop

Fluidized bed reactors exhibit significantly lower pressure drop compared to packed bed reactors due to minimized channeling and enhanced particle suspension.

Catalyst attrition

Fluidized bed reactors exhibit higher catalyst attrition rates due to intense particle collisions and movement compared to the more stable catalyst particles in packed bed reactors.

Axial mixing

Fluidized bed reactors exhibit high axial mixing due to particle suspension and turbulent flow, whereas packed bed reactors show minimal axial mixing with predominantly plug flow behavior.

Heat transfer efficiency

Fluidized bed reactors exhibit significantly higher heat transfer efficiency than packed bed reactors due to enhanced mixing and uniform temperature distribution.

Gas-solid contact

Fluidized bed reactors provide superior gas-solid contact compared to packed bed reactors due to enhanced mixing and uniform gas distribution.

Backmixing

Fluidized bed reactors exhibit significant backmixing due to particle suspension, while packed bed reactors have minimal backmixing because of their fixed catalyst arrangement.

Fluidized bed reactor vs Packed bed reactor Infographic

njnir.com

njnir.com