Risk-based design in chemical engineering prioritizes identifying and mitigating potential hazards through quantitative risk assessments, resulting in flexible solutions tailored to specific process conditions. Prescriptive design relies on strict adherence to established codes and standards, ensuring compliance but often limiting innovation and adaptability. Emphasizing risk-based design enhances safety and efficiency by addressing unique project risks rather than applying one-size-fits-all requirements.

Table of Comparison

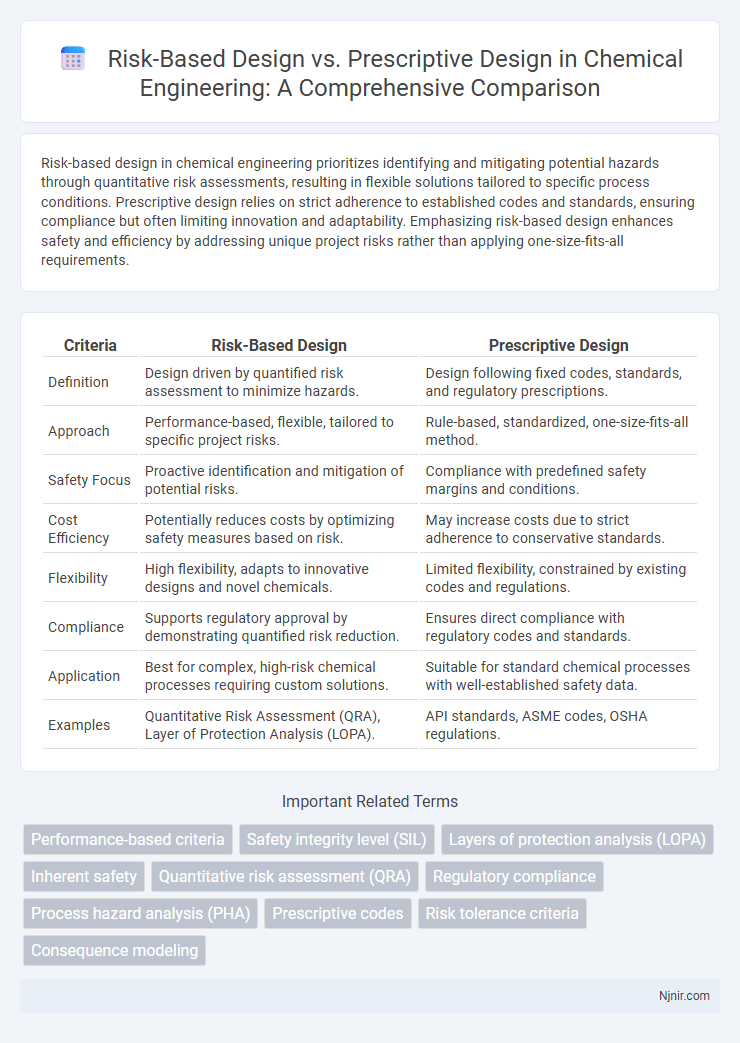

| Criteria | Risk-Based Design | Prescriptive Design |

|---|---|---|

| Definition | Design driven by quantified risk assessment to minimize hazards. | Design following fixed codes, standards, and regulatory prescriptions. |

| Approach | Performance-based, flexible, tailored to specific project risks. | Rule-based, standardized, one-size-fits-all method. |

| Safety Focus | Proactive identification and mitigation of potential risks. | Compliance with predefined safety margins and conditions. |

| Cost Efficiency | Potentially reduces costs by optimizing safety measures based on risk. | May increase costs due to strict adherence to conservative standards. |

| Flexibility | High flexibility, adapts to innovative designs and novel chemicals. | Limited flexibility, constrained by existing codes and regulations. |

| Compliance | Supports regulatory approval by demonstrating quantified risk reduction. | Ensures direct compliance with regulatory codes and standards. |

| Application | Best for complex, high-risk chemical processes requiring custom solutions. | Suitable for standard chemical processes with well-established safety data. |

| Examples | Quantitative Risk Assessment (QRA), Layer of Protection Analysis (LOPA). | API standards, ASME codes, OSHA regulations. |

Introduction to Risk-Based and Prescriptive Design

Risk-based design evaluates potential hazards and their probabilities to develop safety measures tailored to specific project risks, optimizing resource allocation and enhancing system resilience. Prescriptive design relies on established codes and standards prescribing exact requirements, ensuring compliance through predefined rules and uniform safety margins. Understanding these approaches allows engineers to balance innovation and safety by selecting methods aligned with project complexity and regulatory demands.

Core Principles of Prescriptive Design

Prescriptive design relies on established codes and standards that dictate specific methods and criteria to ensure safety and compliance in engineering projects. This approach emphasizes conformity to predefined rules, such as material specifications, load requirements, and construction techniques, minimizing uncertainty through rigorous adherence to guidelines. Core principles of prescriptive design include uniformity, reliability, and regulatory compliance, which streamline decision-making by reducing the need for extensive risk assessment and analysis.

Fundamentals of Risk-Based Design in Chemical Engineering

Risk-based design in chemical engineering emphasizes identifying, assessing, and mitigating potential hazards by quantifying risks associated with chemical processes, enabling optimized safety measures tailored to specific operational scenarios. Unlike prescriptive design, which follows fixed codes and standards, risk-based design utilizes probabilistic risk assessment and decision analysis to prioritize resources efficiently, enhancing system reliability and safety performance. This approach integrates process hazard analysis, fault tree analysis, and consequence modeling to support informed engineering decisions that balance safety, cost, and functionality.

Comparison of Regulatory Frameworks

Risk-based design frameworks prioritize performance outcomes by assessing hazards and implementing controls proportional to identified risks, allowing flexibility in engineering solutions within regulatory limits. Prescriptive design mandates specific methods, materials, and processes dictated by codes and standards, providing clear compliance criteria but limiting innovation. Regulatory agencies adopting risk-based approaches emphasize continuous risk management and documentation, while those enforcing prescriptive rules focus on adherence to established protocols to ensure safety and reliability.

Advantages and Limitations of Prescriptive Approaches

Prescriptive design offers clear, standardized guidelines that simplify compliance and ensure consistency across projects, making it easier to meet regulatory requirements. However, its rigid framework can limit innovation and may not account for unique project-specific risks or evolving technologies. This approach often results in conservative designs that can lead to higher costs and less optimized performance compared to risk-based design methods.

Benefits and Challenges of Risk-Based Design

Risk-based design enhances safety and efficiency by systematically identifying and prioritizing hazards, allowing engineers to allocate resources toward mitigating the most critical risks rather than following rigid codes. This approach offers flexibility and innovation but requires comprehensive risk assessment expertise and robust data, which can increase upfront costs and complexity. Challenges include ensuring consistent risk evaluation standards and managing potential regulatory uncertainties compared to the clear guidelines in prescriptive design.

Case Studies: Industrial Applications

Case studies in industrial applications highlight that risk-based design enables tailored solutions by assessing specific hazards and their probabilities, enhancing safety and cost efficiency in sectors like petrochemicals and aerospace. Prescriptive design, commonly used in structural engineering and manufacturing, adheres to established codes and standards, ensuring regulatory compliance but potentially leading to over-conservative measures and increased costs. Comparative analyses demonstrate risk-based design's advantage in optimizing resource allocation while maintaining safety levels, particularly in complex systems with variable operational conditions.

Integrating Risk Assessment in Process Design

Risk-based design integrates quantitative risk assessment methods directly into process design, enabling engineers to identify, evaluate, and mitigate potential hazards proactively. This approach contrasts with prescriptive design, which follows fixed codes and standards without tailoring solutions to specific risk profiles. Incorporating risk assessment fosters optimized safety, cost-efficiency, and regulatory compliance by addressing unique process vulnerabilities early in the design phase.

Decision-Making Criteria: When to Choose Each Approach

Risk-based design prioritizes decision-making in scenarios with high uncertainty and complex systems, using probabilistic analysis to optimize safety and performance outcomes. Prescriptive design suits cases with well-defined standards and regulatory compliance, providing clear, rule-based criteria for consistent implementation. Choosing between these approaches depends on the level of risk tolerance, availability of data, and the need for flexibility versus standardized guidelines.

Future Trends in Chemical Engineering Design Methods

Future trends in chemical engineering design methods emphasize integrating risk-based design approaches that prioritize hazard identification, quantitative risk assessment, and system reliability over traditional prescriptive design codes. Advances in digital twin technology, machine learning, and real-time data analytics enable more dynamic, adaptive designs that optimize safety and performance while reducing conservatism inherent in prescriptive standards. The shift towards risk-based paradigms supports sustainability and resilience objectives by facilitating proactive decision-making under uncertainty and complex process conditions.

Performance-based criteria

Risk-based design emphasizes performance-based criteria by evaluating potential hazards and system responses, whereas prescriptive design relies on fixed regulatory standards without flexibility for varying risk levels.

Safety integrity level (SIL)

Risk-based design enhances Safety Integrity Level (SIL) achievement by tailoring safety measures to quantified hazard probabilities, whereas prescriptive design relies on fixed standards that may not optimally address specific risk levels.

Layers of protection analysis (LOPA)

Layers of Protection Analysis (LOPA) in risk-based design quantifies and mitigates risks through multiple independent safety layers, whereas prescriptive design relies on fixed regulatory requirements without detailed risk quantification.

Inherent safety

Risk-based design enhances inherent safety by systematically identifying and mitigating hazards, whereas prescriptive design relies on fixed standards that may not address unique or evolving risks effectively.

Quantitative risk assessment (QRA)

Quantitative Risk Assessment (QRA) in risk-based design provides data-driven hazard probability and consequence analysis, optimizing safety measures beyond the fixed criteria of prescriptive design.

Regulatory compliance

Risk-based design enhances regulatory compliance by systematically identifying, assessing, and mitigating potential hazards, whereas prescriptive design follows fixed standards without accounting for unique project-specific risks.

Process hazard analysis (PHA)

Process hazard analysis (PHA) in risk-based design identifies and prioritizes hazards for tailored mitigation, whereas prescriptive design mandates fixed safety measures regardless of specific process risks.

Prescriptive codes

Prescriptive codes provide fixed, standardized requirements ensuring safety and compliance in design by specifying exact methods and materials, contrasting with the flexibility of risk-based design.

Risk tolerance criteria

Risk-based design prioritizes quantifiable risk tolerance criteria to optimize safety and performance, whereas prescriptive design relies on fixed regulatory standards regardless of specific risk levels.

Consequence modeling

Consequence modeling in risk-based design quantitatively assesses potential impacts to optimize safety measures, unlike prescriptive design which follows fixed codes without detailed impact evaluation.

risk-based design vs prescriptive design Infographic

njnir.com

njnir.com