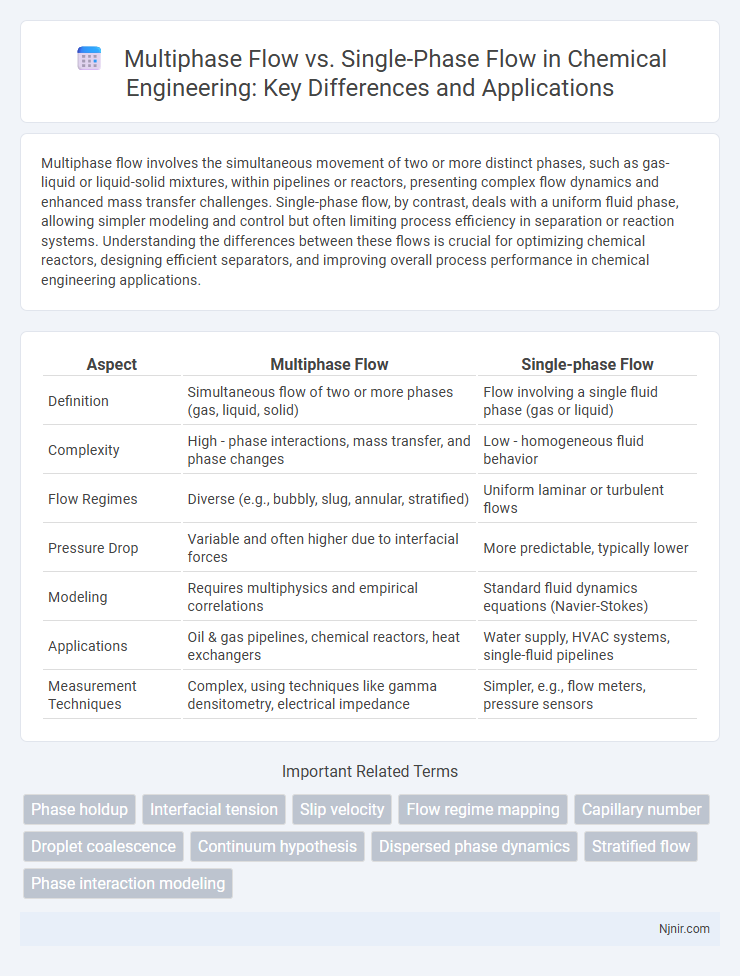

Multiphase flow involves the simultaneous movement of two or more distinct phases, such as gas-liquid or liquid-solid mixtures, within pipelines or reactors, presenting complex flow dynamics and enhanced mass transfer challenges. Single-phase flow, by contrast, deals with a uniform fluid phase, allowing simpler modeling and control but often limiting process efficiency in separation or reaction systems. Understanding the differences between these flows is crucial for optimizing chemical reactors, designing efficient separators, and improving overall process performance in chemical engineering applications.

Table of Comparison

| Aspect | Multiphase Flow | Single-phase Flow |

|---|---|---|

| Definition | Simultaneous flow of two or more phases (gas, liquid, solid) | Flow involving a single fluid phase (gas or liquid) |

| Complexity | High - phase interactions, mass transfer, and phase changes | Low - homogeneous fluid behavior |

| Flow Regimes | Diverse (e.g., bubbly, slug, annular, stratified) | Uniform laminar or turbulent flows |

| Pressure Drop | Variable and often higher due to interfacial forces | More predictable, typically lower |

| Modeling | Requires multiphysics and empirical correlations | Standard fluid dynamics equations (Navier-Stokes) |

| Applications | Oil & gas pipelines, chemical reactors, heat exchangers | Water supply, HVAC systems, single-fluid pipelines |

| Measurement Techniques | Complex, using techniques like gamma densitometry, electrical impedance | Simpler, e.g., flow meters, pressure sensors |

Introduction to Multiphase and Single-Phase Flow in Chemical Engineering

Multiphase flow in chemical engineering involves the simultaneous flow of materials with different phases, such as gas-liquid, liquid-solid, or gas-liquid-solid mixtures, which presents complex interactions affecting mass, momentum, and heat transfer. Single-phase flow refers to the flow of a single fluid phase, either liquid or gas, characterized by relatively stable properties and simpler flow dynamics. Understanding these phenomena is crucial for the design and optimization of reactors, separators, and pipelines in chemical processes.

Fundamental Differences Between Multiphase and Single-Phase Flow

Multiphase flow involves the simultaneous movement of two or more distinct phases such as gas, liquid, or solid within a conduit, unlike single-phase flow which consists of only one homogeneous fluid. The fundamental differences lie in the complex interactions, varying densities, viscosities, and phase distribution patterns that significantly affect pressure drop, flow regimes, and heat transfer characteristics in multiphase systems. Understanding these contrasts is critical for optimizing pipeline design, flow assurance, and process efficiency in industries like oil and gas, chemical processing, and power generation.

Properties and Parameters Affecting Flow Regimes

Multiphase flow involves the simultaneous movement of two or more phases, such as gas-liquid or liquid-solid mixtures, resulting in complex interfacial interactions, variable density, and viscosity that significantly influence flow regimes. Single-phase flow consists of only one fluid phase with uniform properties, leading to simpler flow behavior generally characterized by parameters like Reynolds number and viscosity. Key parameters affecting multiphase flow regimes include phase volume fraction, viscosity ratio, surface tension, flow velocity, and pressure gradients, whereas single-phase flow regimes primarily depend on fluid velocity, viscosity, density, and channel geometry.

Typical Applications of Single-Phase Flow in Industry

Single-phase flow is commonly utilized in industries such as water treatment, chemical manufacturing, and HVAC systems where fluids like water, gases, or pure liquids move without phase change or mixed phases. It ensures efficient transport of heating and cooling fluids in power plants and facilitates precise dosing in pharmaceutical production lines. This flow type supports streamlined operations and accurate process control across various industrial sectors.

Industrial Importance of Multiphase Flow Processes

Multiphase flow processes are crucial in industries such as oil and gas, chemical manufacturing, and power generation due to their ability to handle simultaneous transport of gas, liquid, and solid phases, enhancing efficiency and safety. Understanding the complex interactions in multiphase flow systems optimizes equipment design, reduces operational costs, and prevents pipeline corrosion and blockages. Single-phase flow models fail to capture these dynamics, making multiphase flow analysis essential for accurate prediction and control in industrial applications.

Flow Pattern Identification and Characterization

Multiphase flow involves simultaneous movement of two or more fluid phases, such as gas-liquid or liquid-liquid mixtures, whereas single-phase flow consists of only one fluid phase. Flow pattern identification in multiphase systems is critical, using techniques like image analysis, electrical impedance, and pressure gradient measurements to distinguish regimes such as slug, annular, or stratified flow. Characterization focuses on parameters like phase distribution, velocity profiles, and interfacial area, which influence mass transfer, pressure drop, and overall system efficiency.

Mathematical Modeling of Single-Phase vs Multiphase Systems

Mathematical modeling of single-phase flow relies on simplified Navier-Stokes equations representing continuous, uniform fluid properties, enabling straightforward computational simulations. In contrast, multiphase flow modeling requires complex systems of coupled partial differential equations to capture interactions between distinct phases, incorporating interfacial forces, phase distribution, and mass transfer phenomena. Advanced approaches such as volume-of-fluid, Euler-Euler, and Euler-Lagrange models are essential for accurately predicting multiphase flow dynamics in engineering applications.

Challenges in Measuring and Controlling Multiphase Flow

Measuring and controlling multiphase flow presents significant challenges due to the simultaneous presence of gas, liquid, and sometimes solid phases, which leads to complex flow patterns and interactions that are difficult to accurately characterize. The heterogeneous distribution of phases results in fluctuating flow parameters such as velocity, pressure, and density, complicating sensor calibration and data interpretation. Advanced technologies like multiphase flowmeters and real-time monitoring systems are essential to address these challenges and improve flow assurance in industries such as oil and gas production.

Equipment Design Considerations for Different Flow Types

Multiphase flow equipment design must address challenges such as phase separation, flow regime prediction, and pressure drop management to ensure efficient operation, while single-phase flow equipment focuses more on maintaining steady flow and minimizing friction losses. Materials selection in multiphase systems often requires corrosion resistance and abrasion tolerance due to the diverse properties of gas-liquid-solid mixtures, contrasting with simpler requirements in single-phase systems. Accurate modeling of hydrodynamics and thermal interactions is critical in multiphase flow design to optimize separators, pipelines, and reactors, whereas single-phase flow design relies mainly on well-established fluid mechanics principles.

Recent Advances and Future Trends in Flow Research

Recent advances in multiphase flow research include the development of high-resolution imaging techniques and machine learning algorithms to better predict phase interactions and transitions. Emerging trends emphasize the integration of real-time data analytics with multiphysics simulations to optimize flow control in industrial applications. Future directions focus on enhancing the scalability of multiphase models and improving the accuracy of single-phase flow predictions under complex boundary conditions.

Phase holdup

Phase holdup in multiphase flow represents the volume fraction of each phase within the mixture, significantly affecting flow dynamics, whereas single-phase flow involves only one phase with a holdup of 100%.

Interfacial tension

Interfacial tension in multiphase flow significantly influences phase separation, droplet formation, and flow stability, whereas single-phase flow lacks such interfacial forces, resulting in more uniform fluid behavior.

Slip velocity

Slip velocity in multiphase flow, defined as the relative velocity between different phases, significantly influences phase distribution and pressure drop, whereas single-phase flow exhibits uniform velocity without slip.

Flow regime mapping

Flow regime mapping for multiphase flow identifies complex phase interactions and transitions, contrasting with the uniform behavior observed in single-phase flow regimes.

Capillary number

The Capillary number, representing the ratio of viscous forces to surface tension forces, critically influences multiphase flow behavior by enhancing fluid displacement efficiency, whereas in single-phase flow it remains negligible due to the absence of fluid-fluid interfaces.

Droplet coalescence

Droplet coalescence in multiphase flow significantly alters mass transfer and flow dynamics compared to single-phase flow, where such interfacial phenomena are absent.

Continuum hypothesis

The continuum hypothesis assumes fluids in single-phase flow behave as continuous media with uniform properties, whereas multiphase flow challenges this assumption due to distinct interfaces and phase interactions disrupting uniformity.

Dispersed phase dynamics

Dispersed phase dynamics in multiphase flow involve complex interactions like particle migration, coalescence, and breakup absent in single-phase flow, significantly affecting mass, momentum, and heat transfer.

Stratified flow

Stratified flow in multiphase systems features distinct liquid and gas layers separated by an interface, unlike single-phase flow which involves a homogeneous fluid without phase separation.

Phase interaction modeling

Phase interaction modeling in multiphase flow involves complex momentum, heat, and mass transfer calculations between distinct fluid phases, unlike single-phase flow which requires only homogeneous flow dynamics analysis.

Multiphase flow vs Single-phase flow Infographic

njnir.com

njnir.com