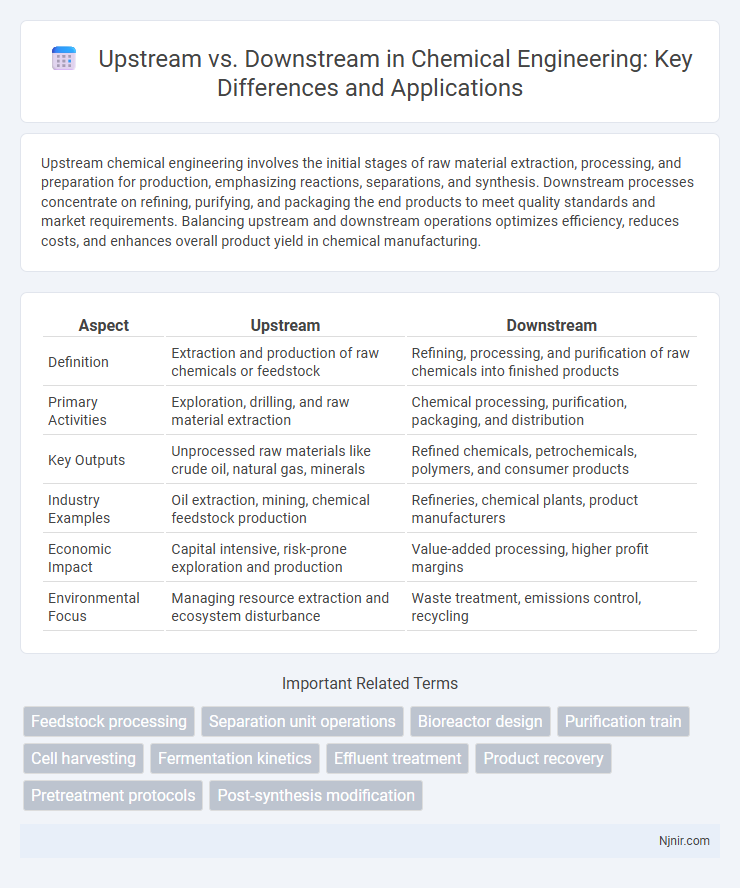

Upstream chemical engineering involves the initial stages of raw material extraction, processing, and preparation for production, emphasizing reactions, separations, and synthesis. Downstream processes concentrate on refining, purifying, and packaging the end products to meet quality standards and market requirements. Balancing upstream and downstream operations optimizes efficiency, reduces costs, and enhances overall product yield in chemical manufacturing.

Table of Comparison

| Aspect | Upstream | Downstream |

|---|---|---|

| Definition | Extraction and production of raw chemicals or feedstock | Refining, processing, and purification of raw chemicals into finished products |

| Primary Activities | Exploration, drilling, and raw material extraction | Chemical processing, purification, packaging, and distribution |

| Key Outputs | Unprocessed raw materials like crude oil, natural gas, minerals | Refined chemicals, petrochemicals, polymers, and consumer products |

| Industry Examples | Oil extraction, mining, chemical feedstock production | Refineries, chemical plants, product manufacturers |

| Economic Impact | Capital intensive, risk-prone exploration and production | Value-added processing, higher profit margins |

| Environmental Focus | Managing resource extraction and ecosystem disturbance | Waste treatment, emissions control, recycling |

Introduction to Upstream and Downstream Processes

Upstream processes involve the initial stages of production, including exploration, extraction, and drilling of raw materials such as crude oil and natural gas. Downstream processes focus on refining, processing, and distribution of finished products like gasoline, diesel, and petrochemicals to end consumers. Both segments are integral to the hydrocarbon value chain, ensuring the transformation from natural resources to market-ready products.

Key Differences Between Upstream and Downstream Operations

Upstream operations in the oil and gas industry focus on exploration, drilling, and production of crude oil and natural gas from reservoirs, involving activities like seismic surveys and well logging. Downstream operations encompass refining crude oil, processing natural gas, and distributing finished products such as gasoline, diesel, and petrochemicals to consumers and industries. Key differences include upstream's emphasis on resource extraction and geological analysis, while downstream centers on refining technology, product formulation, and supply chain management.

Major Steps in Upstream Chemical Engineering

Upstream chemical engineering primarily involves exploration, extraction, and production of raw materials such as crude oil and natural gas through processes like drilling, well completion, and initial separation. Key steps include reservoir evaluation to determine resource viability, designing and implementing drilling operations, and managing well integrity to optimize hydrocarbon recovery. Advanced techniques such as enhanced oil recovery (EOR) and real-time monitoring systems further maximize extraction efficiency in upstream operations.

Main Processes in Downstream Chemical Engineering

Downstream chemical engineering primarily involves refining, purification, and formulation processes that convert raw materials into finished products. Key operations include separation techniques like distillation, extraction, and chromatography, ensuring product quality and compliance with industry standards. These processes are critical in industries such as pharmaceuticals, petrochemicals, and food production, impacting yield and economic efficiency.

Equipment Used in Upstream vs Downstream

Upstream processes in the oil and gas industry utilize equipment such as drilling rigs, blowout preventers, mud pumps, and well logging tools to extract raw hydrocarbons from reservoirs. Downstream operations rely on refining equipment like distillation columns, catalytic crackers, heat exchangers, and storage tanks to process crude oil into usable products such as gasoline, diesel, and petrochemicals. Specialized separation units and chemical reactors are essential in downstream refining to ensure product quality and compliance with environmental standards.

Role of Bioprocessing in Upstream and Downstream

Bioprocessing plays a critical role in both upstream and downstream phases of biopharmaceutical production, where upstream involves the cultivation and growth of microorganisms or cell cultures to produce biological products. In upstream processing, bioreactors and fermentation techniques optimize conditions for maximum yield and quality of the target biomolecules. Downstream, bioprocessing focuses on purification, separation, and formulation processes such as chromatography and filtration, ensuring the final product meets safety and efficacy standards.

Impact on Product Quality: Upstream vs Downstream

Upstream processes directly influence product quality by ensuring raw materials and initial inputs meet stringent specifications, reducing the risk of defects early in production. Downstream activities impact quality through effective testing, refinement, and packaging, which help maintain consistency and prevent contamination or degradation before reaching the customer. Both stages are critical for achieving high-quality outcomes, with upstream focusing on input integrity and downstream emphasizing final product validation.

Economic Considerations in Upstream and Downstream Processing

Economic considerations in upstream processing primarily involve high capital investment in bioreactors and raw materials, with a focus on optimizing cell growth and product yield to enhance cost-efficiency. Downstream processing economics are driven by purification technology expenses, such as chromatography and filtration systems, and the need to achieve product purity and regulatory compliance while minimizing product loss. Both stages require strategic resource allocation to balance operational costs and maximize overall profitability in biomanufacturing.

Challenges and Solutions in Upstream and Downstream Engineering

Upstream engineering faces challenges such as complex reservoir characterization, high drilling costs, and wellbore integrity issues, which require advanced seismic imaging, real-time monitoring, and enhanced drilling technologies as effective solutions. Downstream engineering contends with refining efficiency, environmental emissions, and product quality control, addressed through process optimization, adoption of cleaner technologies, and implementation of robust quality assurance protocols. Both sectors benefit from digitalization, predictive maintenance, and integrated operations to overcome operational complexities and improve overall efficiency.

Future Trends in Upstream and Downstream Chemical Processes

Future trends in upstream chemical processes emphasize the integration of advanced automation, artificial intelligence, and real-time data analytics to optimize raw material extraction and initial synthesis stages. Downstream chemical processes are increasingly adopting sustainable technologies, including biocatalysis and membrane separations, to enhance product purification efficiency and reduce environmental impact. Both sectors are moving towards digital twin implementations and green chemistry principles to drive innovation and operational resilience.

Feedstock processing

Upstream feedstock processing involves extracting and refining raw materials like crude oil and natural gas, while downstream feedstock processing focuses on converting these refined materials into finished products such as fuels, chemicals, and plastics.

Separation unit operations

Upstream separation unit operations primarily involve sedimentation, filtration, and centrifugation to isolate biomass from fermentation broth, while downstream separation emphasizes distillation, extraction, and chromatography to purify target products.

Bioreactor design

Upstream bioreactor design focuses on optimizing cell growth conditions such as nutrient supply and oxygen transfer, while downstream bioreactor design prioritizes efficient product separation, purification, and minimizing shear stress to preserve biomolecules.

Purification train

The purification train in upstream processing primarily focuses on cell harvest and initial product capture, while downstream processing emphasizes product concentration, polishing, and formulation.

Cell harvesting

Cell harvesting in upstream processes involves collecting viable cells for cultivation, while in downstream, it focuses on separating cells to purify the target biomolecules.

Fermentation kinetics

Upstream fermentation kinetics focus on optimizing microbial growth and substrate utilization rates, while downstream fermentation kinetics emphasize product recovery efficiency and purification processes.

Effluent treatment

Effluent treatment in upstream processes primarily targets the removal of raw contaminants and hydrocarbons, while downstream effluent treatment focuses on refining, recycling, and complying with environmental discharge standards.

Product recovery

Upstream processes concentrate on biomass cultivation and fermentation, while downstream recovery involves purification and extraction techniques to maximize product yield and purity.

Pretreatment protocols

Upstream pretreatment protocols involve initial cell harvesting and extraction optimization, while downstream pretreatment focuses on purification and concentration techniques to enhance product yield and quality.

Post-synthesis modification

Upstream processes involve the synthesis of biomolecules, while downstream processes focus on post-synthesis modifications such as purification, refolding, and chemical alterations to enhance product quality and functionality.

Upstream vs downstream Infographic

njnir.com

njnir.com