Plug flow reactors (PFRs) maintain a uniform composition across any cross-section, allowing for higher conversion per unit volume in reactions with positive reaction order compared to continuous stirred-tank reactors (CSTRs), which feature complete mixing and uniform composition throughout the reactor. PFRs are ideal for reactions requiring precise control of residence time and temperature gradients, while CSTRs excel in handling variable feed compositions and allowing easy catalyst replacement. The choice between PFR and CSTR depends on reaction kinetics, heat transfer requirements, and scale of operation to optimize efficiency and product yield.

Table of Comparison

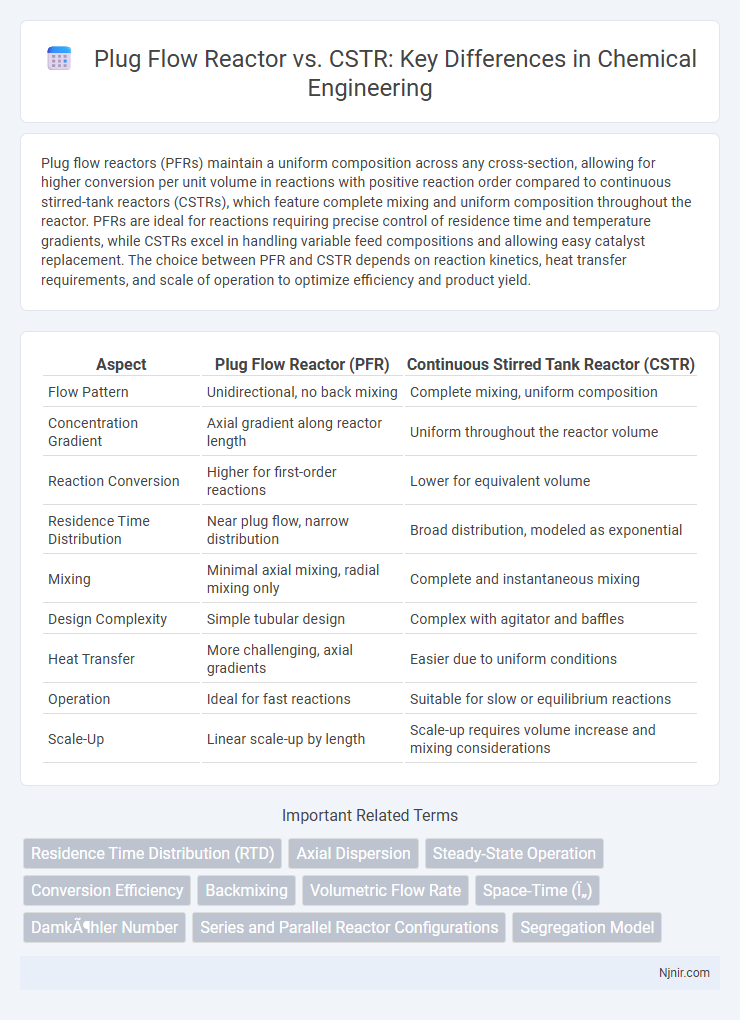

| Aspect | Plug Flow Reactor (PFR) | Continuous Stirred Tank Reactor (CSTR) |

|---|---|---|

| Flow Pattern | Unidirectional, no back mixing | Complete mixing, uniform composition |

| Concentration Gradient | Axial gradient along reactor length | Uniform throughout the reactor volume |

| Reaction Conversion | Higher for first-order reactions | Lower for equivalent volume |

| Residence Time Distribution | Near plug flow, narrow distribution | Broad distribution, modeled as exponential |

| Mixing | Minimal axial mixing, radial mixing only | Complete and instantaneous mixing |

| Design Complexity | Simple tubular design | Complex with agitator and baffles |

| Heat Transfer | More challenging, axial gradients | Easier due to uniform conditions |

| Operation | Ideal for fast reactions | Suitable for slow or equilibrium reactions |

| Scale-Up | Linear scale-up by length | Scale-up requires volume increase and mixing considerations |

Introduction to Plug Flow Reactors and CSTRs

Plug flow reactors (PFRs) feature a cylindrical design where reactants flow in one direction with no back-mixing, ensuring a gradient of concentration and temperature along the reactor length. In contrast, continuous stirred-tank reactors (CSTRs) maintain uniform composition throughout the vessel due to complete mixing, resulting in a steady-state operation with homogeneous conditions. PFRs are ideal for reactions requiring high conversion per unit volume, while CSTRs are suited for reactions benefiting from constant reactant composition.

Fundamental Principles of Plug Flow Reactors

Plug flow reactors (PFRs) operate on the principle that reactants flow through a cylindrical pipe with a uniform velocity profile and no axial mixing, maintaining a concentration gradient along the reactor length. The fundamental design assumes that each fluid element moves as a "plug," experiencing a continuous decrease in reactant concentration and corresponding increase in product concentration. This idealized flow behavior contrasts with continuous stirred-tank reactors (CSTRs), where complete mixing results in uniform concentration throughout the reactor volume.

Core Concepts of Continuous Stirred Tank Reactors (CSTR)

Continuous Stirred Tank Reactors (CSTR) operate with complete mixing, ensuring uniform composition and temperature throughout the reactor volume, which contrasts with the plug flow behavior seen in Plug Flow Reactors (PFR). This mixing allows CSTRs to maintain steady-state operation with a single, consistent reaction environment, ideal for reactions requiring precise control over reaction time and temperature. The core concept of the CSTR design is to continuously input reactants and remove products while sustaining homogeneous conditions, making it suitable for liquid-phase reactions and processes sensitive to concentration and temperature gradients.

Key Design Differences: Plug Flow Reactor vs. CSTR

Plug flow reactors (PFRs) maintain a unidirectional flow with no back-mixing, resulting in concentration gradients along the reactor length and typically higher conversion per reactor volume compared to continuously stirred tank reactors (CSTRs), which feature complete mixing and uniform composition throughout. PFRs operate with varying reactant concentrations, enhancing reaction rates for certain kinetics, while CSTRs sustain steady-state conditions ideal for reactions needing uniform reactant distribution. Design considerations for PFRs emphasize channel length and flow velocity, whereas CSTRs require effective agitation systems and volume control to achieve optimal mixing and reaction performance.

Flow Patterns and Mixing: PFRs Compared to CSTRs

Plug flow reactors (PFRs) exhibit a unidirectional flow pattern where fluid elements move in parallel layers without back-mixing, resulting in a concentration gradient along the reactor length. Continuous stirred-tank reactors (CSTRs) feature complete mixing that ensures uniform reactant concentration throughout the vessel, eliminating spatial concentration gradients. The distinct flow and mixing characteristics of PFRs promote higher conversion per unit volume for reactions with positive reaction orders, whereas CSTRs provide steady-state operation with homogenous reaction conditions.

Reaction Kinetics and Performance Analysis

Plug flow reactors (PFR) exhibit a concentration gradient along the reactor length, allowing for higher conversion rates in fast, irreversible reactions due to minimal back-mixing and ideal plug flow behavior. Continuous stirred-tank reactors (CSTR) maintain uniform concentration and temperature throughout, leading to lower conversion per reactor volume for the same reaction due to complete mixing and back-mixing effects. Performance analysis shows PFRs are preferred for first-order reactions and cases requiring high conversion, whereas CSTRs are advantageous for reactions demanding uniform reaction conditions or where reaction kinetics benefit from continuous mixing.

Conversion and Yield: Industrial Application Scenarios

Plug flow reactors (PFRs) typically achieve higher conversion per unit volume and better yield for reactions with fast kinetics due to their ideal plug flow behavior, making them suitable for large-scale continuous processes like petrochemical cracking. Continuous stirred-tank reactors (CSTRs) offer uniform composition and temperature, enabling precise control for reactions requiring thorough mixing, ideal for biochemical fermentations and polymerizations with slower reaction rates. Industrial applications favor PFRs when maximum conversion and yield per pass are critical, while CSTRs are preferred for reactions needing consistent product quality and ease of operation in batch or continuous modes.

Advantages and Limitations of PFRs and CSTRs

Plug flow reactors (PFRs) provide high conversion per volume due to their ideal plug flow pattern, making them ideal for fast, irreversible reactions with sharp residence time control; however, they face challenges in scale-up and mixing inefficiencies along the reactor length. Continuous stirred-tank reactors (CSTRs) offer excellent mixing and uniform composition throughout, simplifying temperature and concentration control, but generally require larger volumes for equivalent conversion and exhibit back-mixing that reduces overall reaction efficiency. The choice between PFR and CSTR depends on reaction kinetics, desired conversion, space velocity, and operational flexibility.

Selection Criteria for Reactor Choice

The selection criteria for choosing between a Plug Flow Reactor (PFR) and a Continuous Stirred Tank Reactor (CSTR) primarily depend on reaction kinetics, conversion requirements, and mixing characteristics. PFRs are preferred for first-order reactions and when high conversion per unit volume is needed, offering a concentration gradient along the reactor length that enhances efficiency in certain processes. CSTRs provide uniform composition throughout the reactor, making them suitable for reactions requiring controlled temperature and composition, or for processes with slow kinetics and multiple reaction steps.

Future Trends and Innovations in Reactor Design

Future trends in reactor design emphasize integrating advanced plug flow reactors (PFRs) with continuous stirred-tank reactors (CSTRs) to enhance process intensification and energy efficiency in chemical manufacturing. Innovations include modular, scalable reactor units combined with AI-driven process control to optimize reaction kinetics and reduce operational costs. Emerging materials such as corrosion-resistant alloys and novel catalysts improve reactor durability and selectivity, supporting sustainable production goals across pharmaceutical and petrochemical industries.

Residence Time Distribution (RTD)

Plug flow reactors exhibit narrow residence time distribution with nearly uniform residence time, while CSTRs display broad residence time distribution due to complete mixing and variable residence times.

Axial Dispersion

Axial dispersion in plug flow reactors is minimal, promoting ideal radial mixing with no back-mixing, whereas continuous stirred-tank reactors (CSTRs) exhibit significant axial dispersion due to complete mixing and uniform concentration throughout the reactor volume.

Steady-State Operation

Plug flow reactors maintain steady-state operation by ensuring unidirectional flow with no back-mixing, whereas continuous stirred-tank reactors achieve steady-state through complete mixing and uniform concentration throughout the reactor volume.

Conversion Efficiency

Plug flow reactors achieve higher conversion efficiency than continuous stirred-tank reactors by maintaining a concentration gradient along the reactor length, which enhances reaction rates and minimizes back-mixing.

Backmixing

Plug flow reactors minimize backmixing by maintaining a unidirectional flow, while continuous stirred-tank reactors (CSTR) exhibit complete backmixing due to their uniform composition throughout.

Volumetric Flow Rate

Plug flow reactors maintain a consistent volumetric flow rate with minimal axial mixing, while CSTRs experience variable volumetric flow rates due to complete mixing and residence time distribution.

Space-Time (τ)

Space-time (t) in a Plug Flow Reactor (PFR) is generally shorter and more efficient than in a Continuous Stirred Tank Reactor (CSTR), due to the PFR's uninterrupted flow and minimal back-mixing, leading to higher conversion per unit volume.

Damköhler Number

The Damkohler Number quantifies the ratio of reaction rate to flow rate, with Plug Flow Reactors (PFR) typically achieving higher conversion efficiency than Continuous Stirred Tank Reactors (CSTR) at the same Damkohler number due to their differing flow and mixing characteristics.

Series and Parallel Reactor Configurations

Plug flow reactors arranged in series provide higher conversion efficiency for reactions with intermediate selectivity, while continuous stirred-tank reactors in parallel offer better temperature control and flexibility for handling variable feed compositions.

Segregation Model

The Segregation Model quantifies mixing inefficiencies by comparing concentration variance in Plug Flow Reactors (PFRs), where axial dispersion is minimal, to Continuous Stirred Tank Reactors (CSTRs), characterized by complete mixing and uniform concentration throughout.

Plug flow reactor vs CSTR Infographic

njnir.com

njnir.com