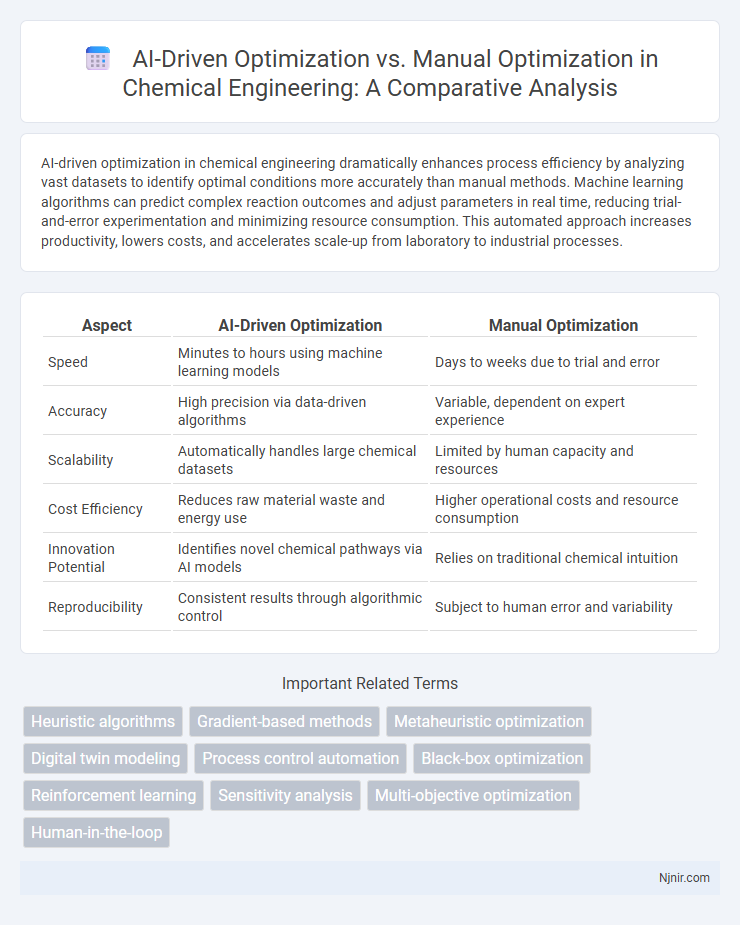

AI-driven optimization in chemical engineering dramatically enhances process efficiency by analyzing vast datasets to identify optimal conditions more accurately than manual methods. Machine learning algorithms can predict complex reaction outcomes and adjust parameters in real time, reducing trial-and-error experimentation and minimizing resource consumption. This automated approach increases productivity, lowers costs, and accelerates scale-up from laboratory to industrial processes.

Table of Comparison

| Aspect | AI-Driven Optimization | Manual Optimization |

|---|---|---|

| Speed | Minutes to hours using machine learning models | Days to weeks due to trial and error |

| Accuracy | High precision via data-driven algorithms | Variable, dependent on expert experience |

| Scalability | Automatically handles large chemical datasets | Limited by human capacity and resources |

| Cost Efficiency | Reduces raw material waste and energy use | Higher operational costs and resource consumption |

| Innovation Potential | Identifies novel chemical pathways via AI models | Relies on traditional chemical intuition |

| Reproducibility | Consistent results through algorithmic control | Subject to human error and variability |

Introduction to Optimization in Chemical Engineering

AI-driven optimization in chemical engineering leverages machine learning algorithms and advanced computational models to enhance process efficiency, reduce energy consumption, and improve product yield with high precision. Manual optimization relies on heuristic methods and expert intuition, which can be time-consuming and less adaptable to complex, nonlinear systems. Integrating AI-driven strategies accelerates decision-making and enables real-time adjustments, outperforming traditional manual approaches in process control and optimization.

Overview of Manual Optimization Techniques

Manual optimization techniques rely on human expertise to analyze and enhance system performance through incremental adjustments and rule-based strategies. Common methods include parameter tuning, heuristic analysis, and trial-and-error experimentation aimed at achieving optimal results within specific constraints. These techniques often require significant domain knowledge and time investment but provide granular control over the optimization process.

Emergence of AI-Driven Optimization Methods

AI-driven optimization methods have transformed industries by leveraging machine learning algorithms and massive datasets to identify patterns and solutions unattainable through manual optimization. These advanced techniques enable real-time decision-making and adaptive improvements, outperforming traditional trial-and-error approaches in efficiency and accuracy. The emergence of AI-driven optimization has accelerated innovation cycles and significantly enhanced predictive capabilities across sectors like logistics, finance, and manufacturing.

Comparative Efficiency: AI vs. Manual Approaches

AI-driven optimization leverages machine learning algorithms and data analytics to rapidly identify patterns and generate solutions, significantly reducing the time required compared to manual optimization. Manual approaches rely heavily on human intuition and iterative trial-and-error processes, often resulting in slower adjustments and limited scalability. Studies show AI can improve optimization efficiency by up to 50%, enabling faster decision-making and enhanced accuracy across complex datasets.

Data Requirements and Model Complexity

AI-driven optimization requires large volumes of high-quality, diverse datasets to effectively train complex models capable of identifying patterns and making accurate predictions. Manual optimization relies on smaller, often less structured data inputs, limiting its ability to handle multifaceted scenarios and adapt to dynamic environments. The complexity of AI models, such as deep neural networks, enables advanced feature extraction and continuous learning, whereas manual optimization depends on simpler algorithms and human expertise with limited scalability.

Scalability of Optimization Solutions

AI-driven optimization significantly outperforms manual optimization in scalability, efficiently processing vast datasets and complex variables without performance degradation. Automated algorithms adapt dynamically to changing parameters, enabling continuous improvement across large-scale operations. Manual optimization struggles with time constraints and human error, limiting its effectiveness in expanding system demands.

Impact on Process Safety and Reliability

AI-driven optimization enhances process safety and reliability by continuously analyzing real-time data to predict and prevent failures, reducing human error and enabling proactive maintenance. Manual optimization relies on periodic inspections and operator experience, often resulting in delayed hazard detection and inconsistent safety measures. The integration of AI enables faster identification of potential risks and optimizes operational parameters, significantly improving overall safety performance and system reliability.

Economic Benefits and Cost Implications

AI-driven optimization significantly reduces operational costs by automating complex decision-making processes, resulting in higher efficiency and resource utilization compared to manual optimization. Companies leveraging AI experience increased revenue through real-time data analysis, predictive modeling, and adaptive strategies that minimize waste and improve asset performance. The initial investment in AI technology is offset by long-term savings, reduced labor expenses, and accelerated ROI, making AI a cost-effective alternative to traditional manual optimization methods.

Challenges in Implementation and Integration

Implementing AI-driven optimization faces challenges such as high initial costs, complex data integration, and the need for specialized expertise to ensure accurate model training and validation. Manual optimization struggles with scalability, human error, and time-consuming processes, limiting responsiveness to dynamic market conditions. Integrating AI systems requires alignment with existing IT infrastructure and data governance policies, often demanding significant changes to workflows and employee training programs.

Future Prospects of AI in Chemical Engineering Optimization

AI-driven optimization in chemical engineering offers unprecedented efficiency by rapidly analyzing complex datasets and predicting optimal process conditions, surpassing the limitations of manual optimization techniques. Advanced machine learning models and real-time data integration enable continuous process improvements and adaptive control strategies, driving significant enhancements in yield, energy consumption, and environmental sustainability. Future prospects include the integration of AI with digital twins and autonomous laboratories, revolutionizing chemical process development and accelerating innovation cycles.

Heuristic algorithms

Heuristic algorithms in AI-driven optimization significantly outperform manual optimization by efficiently solving complex problems through iterative, experience-based techniques that adapt and improve over time.

Gradient-based methods

Gradient-based AI-driven optimization significantly accelerates convergence and enhances accuracy compared to traditional manual optimization by leveraging automatic differentiation and adaptive learning rates.

Metaheuristic optimization

Metaheuristic optimization algorithms significantly outperform manual optimization by efficiently navigating complex search spaces and dynamically adapting to problem constraints through AI-driven heuristics.

Digital twin modeling

AI-driven optimization in Digital Twin modeling enables real-time data integration and adaptive simulations, surpassing manual optimization by enhancing accuracy, efficiency, and predictive capabilities.

Process control automation

AI-driven process control automation enhances efficiency and accuracy by continuously analyzing real-time data, reducing human error, and enabling dynamic adjustments compared to manual optimization methods.

Black-box optimization

AI-driven black-box optimization outperforms manual optimization by efficiently exploring complex, high-dimensional spaces without requiring explicit model knowledge, leading to faster convergence and improved solution quality.

Reinforcement learning

Reinforcement learning enhances AI-driven optimization by enabling adaptive, self-improving decision-making processes that outperform manual optimization in complex dynamic environments.

Sensitivity analysis

AI-driven optimization enhances sensitivity analysis by rapidly identifying critical variables and adapting to data variations, outperforming manual optimization methods in accuracy and efficiency.

Multi-objective optimization

AI-driven multi-objective optimization outperforms manual optimization by efficiently balancing complex trade-offs between conflicting objectives through automated algorithms and adaptive learning.

Human-in-the-loop

AI-driven optimization with human-in-the-loop integrates automated algorithms and expert judgment to enhance decision accuracy, efficiency, and adaptability compared to solely manual optimization.

AI-driven optimization vs manual optimization Infographic

njnir.com

njnir.com