Hydrodynamic cavitation generates vapor bubbles through pressure changes caused by fluid flow constrictions, offering efficient scalability and lower energy consumption compared to acoustic cavitation, which relies on high-frequency sound waves to induce bubble formation. Hydrodynamic cavitation provides enhanced mass transfer and rapid reaction rates, making it ideal for large-scale chemical processing applications. Acoustic cavitation excels in precise control over bubble dynamics but often requires higher energy input and is better suited for laboratory or small-scale setups.

Table of Comparison

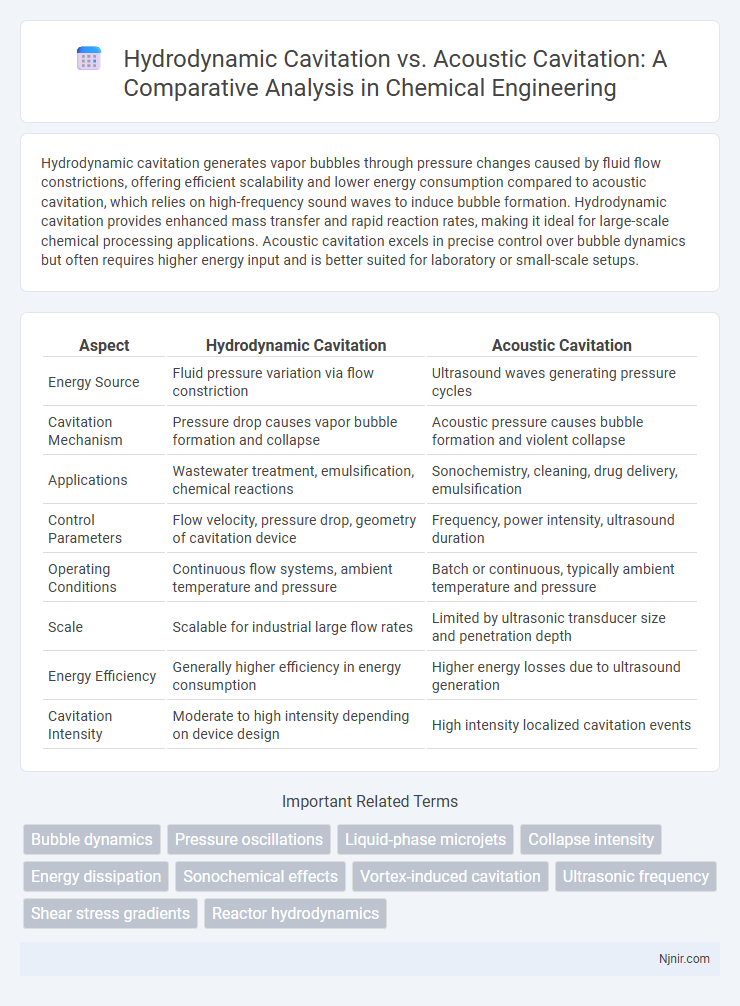

| Aspect | Hydrodynamic Cavitation | Acoustic Cavitation |

|---|---|---|

| Energy Source | Fluid pressure variation via flow constriction | Ultrasound waves generating pressure cycles |

| Cavitation Mechanism | Pressure drop causes vapor bubble formation and collapse | Acoustic pressure causes bubble formation and violent collapse |

| Applications | Wastewater treatment, emulsification, chemical reactions | Sonochemistry, cleaning, drug delivery, emulsification |

| Control Parameters | Flow velocity, pressure drop, geometry of cavitation device | Frequency, power intensity, ultrasound duration |

| Operating Conditions | Continuous flow systems, ambient temperature and pressure | Batch or continuous, typically ambient temperature and pressure |

| Scale | Scalable for industrial large flow rates | Limited by ultrasonic transducer size and penetration depth |

| Energy Efficiency | Generally higher efficiency in energy consumption | Higher energy losses due to ultrasound generation |

| Cavitation Intensity | Moderate to high intensity depending on device design | High intensity localized cavitation events |

Introduction to Cavitation Phenomena in Chemical Engineering

Hydrodynamic cavitation occurs when a liquid passes through a constricted region, causing a localized drop in pressure below the vapor pressure, leading to bubble formation and collapse, which enhances mixing and mass transfer in chemical processes. Acoustic cavitation is induced by ultrasonic waves creating cyclic high and low-pressure zones, generating microbubbles that implode and release intense energy, useful for applications such as sonochemical reactions and waste treatment. Both phenomena exploit cavitation effects to improve reaction rates, emulsification, and pollutant degradation, but hydrodynamic cavitation is often favored for scalability and lower energy consumption in industrial chemical engineering.

Fundamental Principles of Hydrodynamic Cavitation

Hydrodynamic cavitation arises when liquid pressure drops below its vapor pressure as it flows through constricted geometries such as orifices or venturi tubes, causing the formation and subsequent collapse of vapor bubbles. This pressure variation is primarily governed by fluid velocity changes and flow conditions, resulting in energy release that enhances mixing, chemical reactions, and cleaning processes. Unlike acoustic cavitation, which relies on ultrasonic waves to induce bubble formation, hydrodynamic cavitation leverages mechanical flow dynamics for bubble generation and collapse.

Fundamental Principles of Acoustic Cavitation

Acoustic cavitation occurs when ultrasonic waves generate alternating high-pressure and low-pressure cycles in a liquid, leading to the formation, growth, and violent collapse of microbubbles. This collapse produces localized extreme temperatures and pressures, resulting in intense shear forces and chemical reactions. In contrast, hydrodynamic cavitation arises from pressure changes due to fluid flow through constrictions, relying on liquid velocity and geometric factors rather than acoustic energy.

Mechanisms of Bubble Formation and Collapse

Hydrodynamic cavitation occurs when liquid flows through a constriction, causing a local drop in pressure below vapor pressure, leading to bubble nucleation. Acoustic cavitation involves the formation and collapse of bubbles due to pressure variations induced by high-frequency ultrasonic waves. The collapse of bubbles in hydrodynamic cavitation is driven by fluid velocity changes, while in acoustic cavitation, it is triggered by the oscillating pressure field, resulting in varying intensities of localized energy release.

Equipment and Reactor Designs for Hydrodynamic Cavitation

Hydrodynamic cavitation equipment typically includes Venturi tubes, orifice plates, and rotor-stator reactors designed to create localized pressure drops, inducing vapor bubble formation and collapse. Reactor designs optimize fluid flow rate, pressure differentials, and geometry to enhance cavitation intensity, enabling efficient mixing, emulsification, and pollutant degradation. Compared to acoustic cavitation that relies on ultrasonic transducers, hydrodynamic systems enable scalable, energy-efficient processing with lower operational costs in industrial applications.

Equipment and Reactor Designs for Acoustic Cavitation

Acoustic cavitation equipment primarily utilizes ultrasonic transducers and ultrasonic horns to generate intense sound waves that induce bubble formation and collapse within liquids. Reactor designs for acoustic cavitation often feature flow-through ultrasonic reactors or batch systems equipped with multiple transducers to ensure uniform cavitation distribution and process scalability. Optimization of reactor geometry, frequency, and power density is critical for maximizing cavitation intensity and operational efficiency in applications such as wastewater treatment, chemical synthesis, and material processing.

Comparative Analysis: Energy Efficiency and Operational Costs

Hydrodynamic cavitation generates vapor bubbles through fluid pressure changes in a flow system, offering higher energy efficiency by utilizing existing hydraulic energy with minimal external input. Acoustic cavitation relies on ultrasonic waves, which consume significant electrical power, resulting in higher operational costs and lower energy efficiency. Comparative studies show hydrodynamic cavitation systems can reduce energy consumption by up to 40% compared to acoustic cavitation, making them more cost-effective for large-scale industrial applications.

Impact on Chemical Reaction Enhancement and Process Intensification

Hydrodynamic cavitation generates controlled vapor bubbles through pressure variations in fluid flow, leading to intense localized shear and turbulence that significantly enhance chemical reaction rates and process intensification by improving mass transfer and promoting radical formation. Acoustic cavitation uses high-frequency ultrasonic waves to induce bubble oscillation and collapse, producing localized hotspots with extreme temperatures and pressures that accelerate chemical transformations and improve process efficiency. Both methods intensify chemical reactions but hydrodynamic cavitation is often preferred for scalable industrial applications due to its energy efficiency and easier integration into continuous flow systems.

Applications in Wastewater Treatment and Pollution Control

Hydrodynamic cavitation generates localized high temperatures and pressures through fluid flow constrictions, enhancing the breakdown of organic pollutants and improving biodegradability in wastewater treatment. Acoustic cavitation, induced by ultrasonic waves, produces intense microbubbles that implode and generate reactive radicals capable of degrading complex contaminants and disinfection of pathogens. Both methods offer sustainable solutions for advanced oxidation processes, with hydrodynamic cavitation favored for large-scale continuous operations and acoustic cavitation for targeted pollutant removal in industrial effluents.

Challenges, Limitations, and Future Prospects

Hydrodynamic cavitation faces challenges such as scalability issues and high energy consumption, limiting its broader industrial application. Acoustic cavitation is constrained by difficulties in controlling bubble dynamics and localized energy distribution, affecting process uniformity. Future prospects include integrating computational fluid dynamics for optimized designs and combining hydrodynamic and acoustic methods to enhance efficiency and reduce operational costs.

Bubble dynamics

Hydrodynamic cavitation generates bubble collapse through liquid flow velocity changes causing low-pressure zones, while acoustic cavitation uses ultrasonic waves to create oscillating bubble dynamics, affecting bubble size, collapse intensity, and frequency.

Pressure oscillations

Hydrodynamic cavitation generates pressure oscillations through fluid flow velocity changes causing bubble collapse, whereas acoustic cavitation induces pressure oscillations via high-frequency ultrasonic waves leading to bubble formation and implosion.

Liquid-phase microjets

Hydrodynamic cavitation generates high-velocity liquid-phase microjets through fluid flow constrictions, whereas acoustic cavitation produces microjets via bubble collapse induced by ultrasonic waves.

Collapse intensity

Hydrodynamic cavitation generates higher collapse intensity due to rapid pressure changes in fluid flow, whereas acoustic cavitation produces comparatively lower collapse intensity through ultrasonic wave-induced bubble oscillations.

Energy dissipation

Hydrodynamic cavitation generates higher localized energy dissipation rates through rapid liquid pressure changes and bubble collapse compared to acoustic cavitation, which relies on ultrasonic waves to induce cavitation.

Sonochemical effects

Hydrodynamic cavitation generates intense shear forces and localized hotspots through liquid flow-induced bubble collapse, while acoustic cavitation produces oscillating bubbles via ultrasonic waves, both enhancing sonochemical effects such as accelerated chemical reactions and pollutant degradation.

Vortex-induced cavitation

Vortex-induced cavitation in hydrodynamic cavitation generates intense localized pressure drops through vortex formation, offering more controlled and energy-efficient bubble collapse compared to the ultrasonic wave-driven bubble dynamics of acoustic cavitation.

Ultrasonic frequency

Ultrasonic frequency acoustic cavitation generates high-intensity microbubbles through rapid pressure fluctuations, whereas hydrodynamic cavitation creates vapor bubbles via fluid velocity changes without relying on ultrasonic waves.

Shear stress gradients

Hydrodynamic cavitation generates higher shear stress gradients than acoustic cavitation, enhancing mass transfer and reaction rates in fluid processing applications.

Reactor hydrodynamics

Hydrodynamic cavitation generates vapor bubbles through pressure fluctuations in fluid flowing within a reactor, offering controlled and scalable reactor hydrodynamics compared to the ultrasonic wave-induced bubble formation in acoustic cavitation reactors.

hydrodynamic cavitation vs acoustic cavitation Infographic

njnir.com

njnir.com